Exhaust gas recycling device for vacuum pump

A technology of tail gas recovery and vacuum pump, which is applied to parts, pump elements, and steam condensation of elastic fluid pumping devices. It can solve problems such as incomplete sealing, solvent loss, and air pollution, and avoid air pollution. The effect of reducing the chance of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

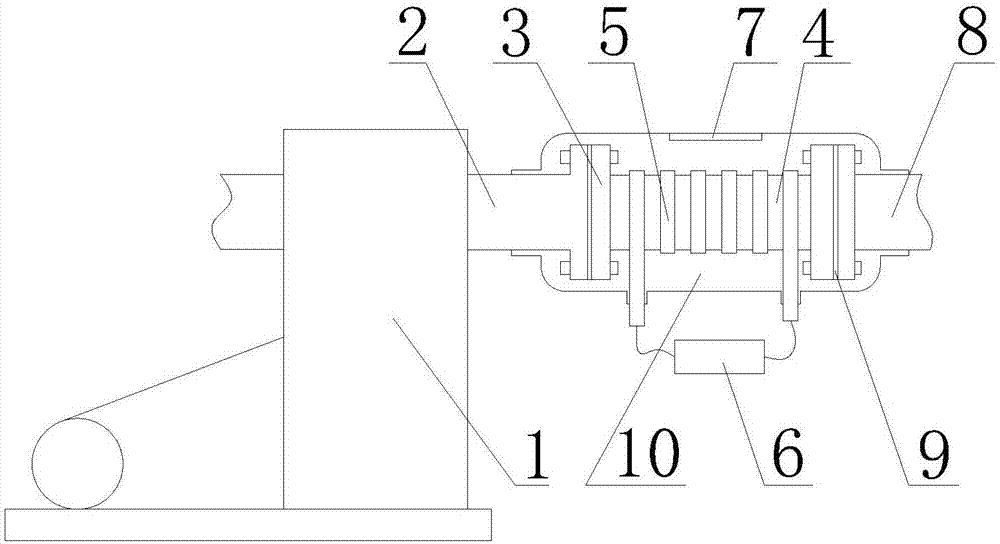

[0017] Such as figure 1 As shown, the present invention is used for the tail gas recovery device of vacuum pump, comprises vacuum pump 1, tail gas recovery pipe 8, exhaust pipe 4, condensing device (not shown in the figure) and safety bag 10, the tail gas discharge port 2 of vacuum pump 1 and tail gas The recovery pipe 8 is connected, and the exhaust pipe 4 is installed between the exhaust gas discharge port 2 of the vacuum pump 1 and the exhaust gas recovery pipe 8. The condensing device is composed of a condensing pipe 5 and a condenser 6 equipped with frozen brine, and the condensing pipe 5 is wound on the exhaust pipe. 4, the two ends of the condensation pipe 5 are respectively connected to the water inlet and the water outlet of the condenser 6, and a corrosion-resistant sealing ring 9 is installed between the joint 3 at the two ends of the exhaust pipe 4 and the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com