Arc welding power source current double-closed-loop control method

A technology of double closed-loop control and arc welding power supply, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that the output current cannot be adjusted accurately, and achieve the effect of improving response speed and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the patent of the present invention are described below in conjunction with the accompanying drawings.

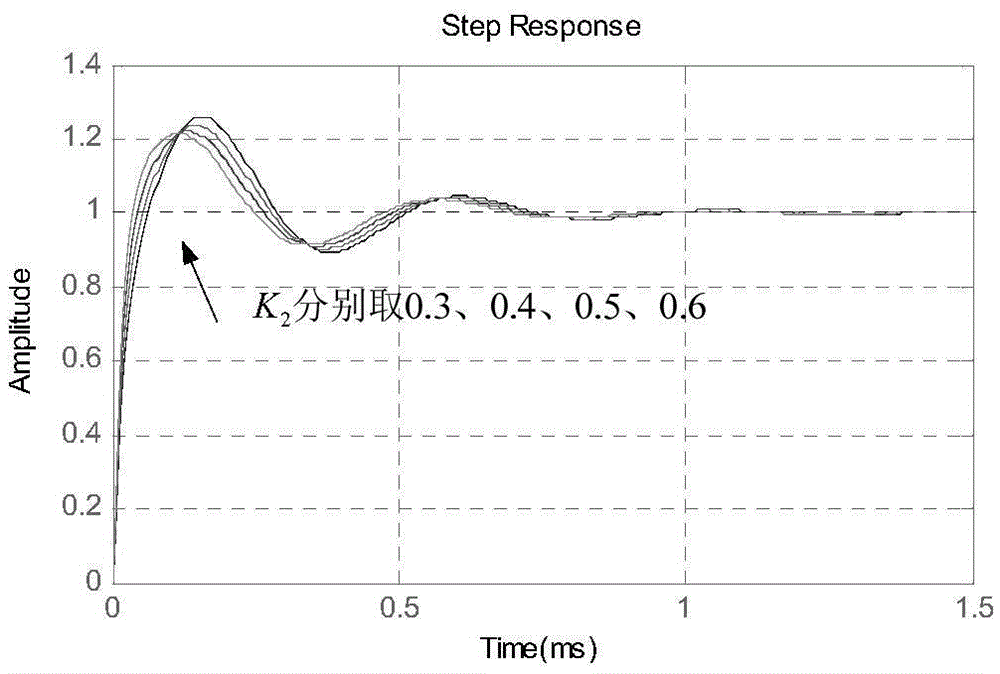

[0027] like figure 1 The topology of the arc welding inverter power supply shown is shown in the figure. The main circuit can be regarded as a DC-DC conversion process. The current control system mainly consists of the following parts: current sampling and conditioning circuit, current control module, current drive circuit, and current double closed loop respectively. It is the current outer loop with current feed-forward control and the current inner loop to realize the current regulation of the main circuit. The arc welding inverter power supply of the present invention complies with the ZX7-400 standard, and the main parameters of the system are shown in Table 1.

[0028] Table 1 The main parameters of the system

[0029] parameters

value

Input voltage U i / V

540

Switching frequency f s / k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com