Composite material with nano-nickel particles and nano-palladium particles on graphene and preparation method of composite material

A composite material and nano-nickel technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of undiscovered graphene and missing carbon atoms, etc. To achieve the effect of short experiment period, good dispersion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

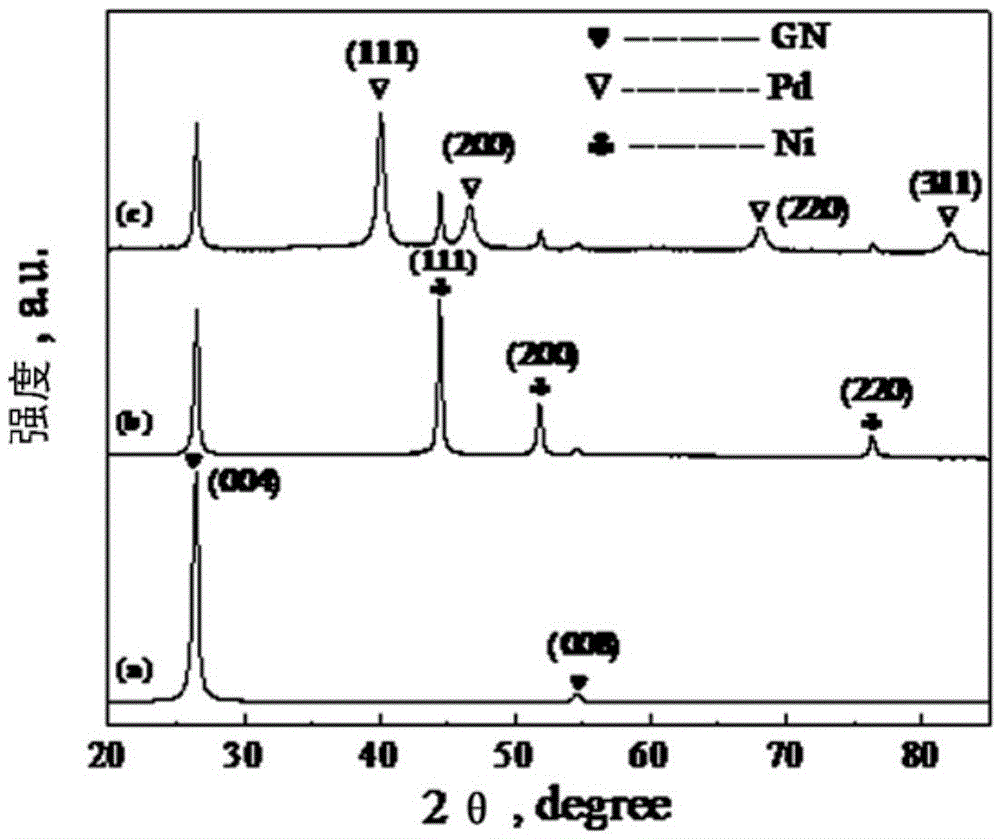

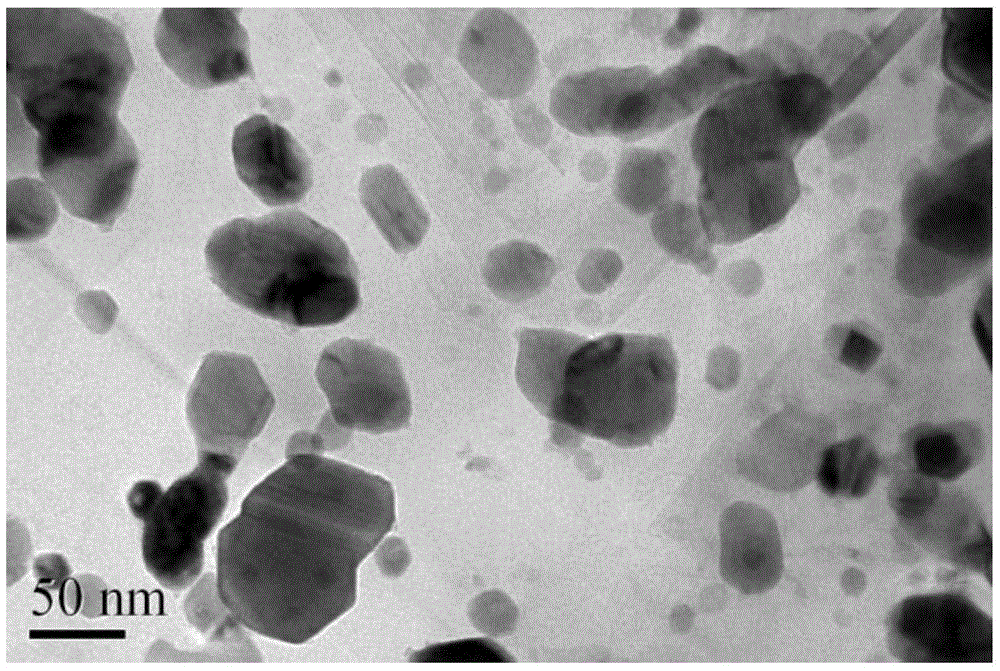

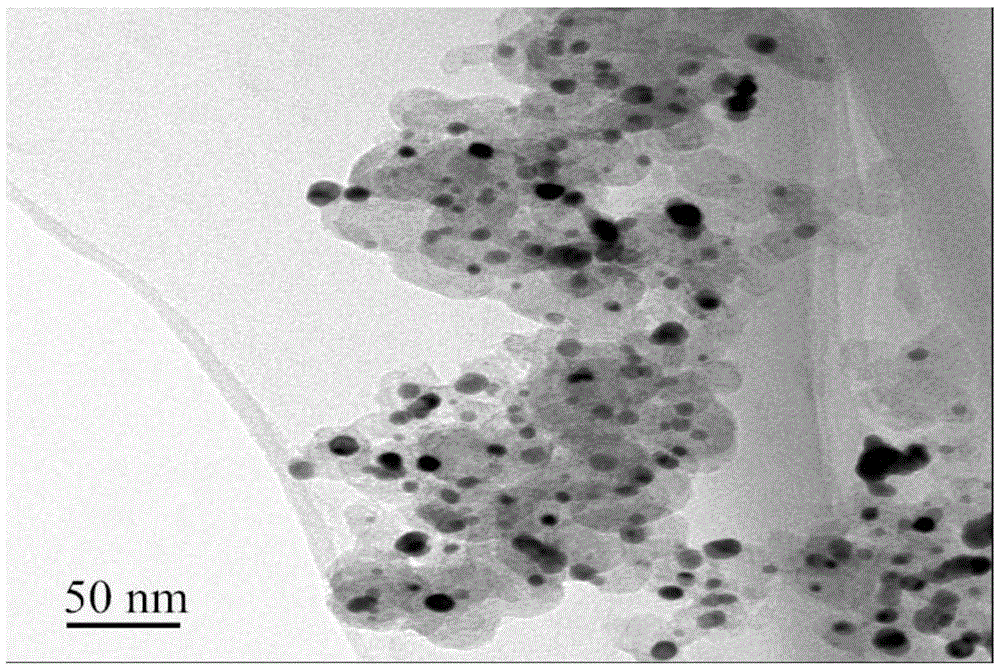

[0048] This embodiment prepares a graphene-loaded nano-nickel particle and palladium particle composite material, wherein the mass ratio of the nano-nickel particle, nano-palladium particle and graphene is 1:1:8, and the nano-nickel particle loaded on the graphene surface The average particle sizes of nickel particles and palladium particles are respectively 21nm and 9nm, which are prepared by the following method:

[0049] (1) Put graphene nanosheets into concentrated HNO 3 In the solution, reflux at 140°C for 8h, cool to room temperature, wash with deionized water until neutral and dry, wherein the drying temperature is 80°C to obtain functionalized graphene powder;

[0050] (2) 0.8g functionalized graphene powder and 0.4955gNi(NO 3 ) 2 ·6H 2 O (the mass ratio of nickel to graphene is 1:8) was added to 30mL of acetone reagent, mixed ultrasonically and then dried at 80°C; the dried powder was placed in an argon atmosphere at 400°C Calcined for 4 hours, then reduced in a h...

Embodiment 2

[0056] This embodiment prepares a graphene-loaded nano-nickel particle and palladium particle composite material, wherein the mass ratio of the nano-nickel particle, nano-palladium particle and graphene is 1:1:3, and the nano-nickel particle loaded on the graphene surface The average particle size of nickel particle and palladium particle is respectively 22nm, 9nm, and it adopts following method to prepare:

[0057] (1) Put graphene nanosheets into concentrated HNO 3 In the solution, reflux at 140°C for 8 hours, cool to room temperature, wash with deionized water to neutrality and dry to obtain functionalized graphene powder;

[0058] (2) 0.6g functionalized graphene powder and 0.9910gNi(NO 3 ) 2 ·6H 2 O (the mass ratio of nickel to graphene is 1:3) was added to 30mL of acetone reagent, mixed ultrasonically and then dried; the dried powder was calcined in an argon atmosphere at 400°C for 4h, and then heated at 450°C Reduction in a hydrogen atmosphere for 4 hours, and final...

Embodiment 3

[0063] This embodiment prepares a graphene-loaded nano-nickel particle and palladium particle composite material, wherein the mass ratio of the nano-nickel particle, nano-palladium particle and graphene is 3:3:4, and the nano-nickel particle loaded on the graphene surface The average particle size of nickel particle and palladium particle is respectively 24nm, 12nm, and it adopts following method to prepare:

[0064] (1) Put graphene nanosheets into concentrated HNO 3 In the solution, reflux at 140°C for 8 hours, cool to room temperature, wash with deionized water to neutrality and dry to obtain functionalized graphene powder;

[0065] (2) 0.4g functionalized graphene powder and 1.4865gNi(NO 3 ) 2 ·6H 2 O (the mass ratio of nickel to graphene is 3:4) was added to 30mL of acetone reagent, mixed ultrasonically and then dried; the dried powder was calcined in an argon atmosphere at 400°C for 4h, and then heated at 450°C Reduction in a hydrogen atmosphere for 4 hours, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com