Polypropylene/polylactic acid interwoven composite pelvic floor mesh and preparation method thereof

A polylactic acid and polypropylene technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as stiffness in hand, achieve stable mechanical properties, reduce recurrence rate, and improve quality of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

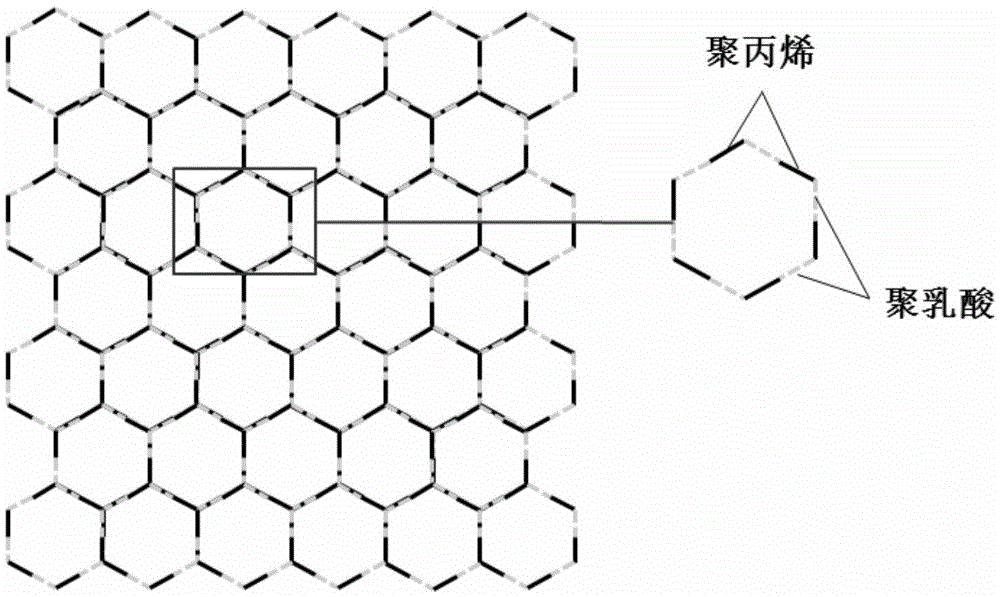

[0029] (1) Patch weaving: use polypropylene monofilament (medical grade) with a diameter of 0.1mm and polylactic acid monofilament (medical grade) with a diameter of 0.12mm as raw materials, and the machine number is 20E, 2 bar raschel Weave on the warp knitting machine to make a patch with a hexagonal mesh structure, and the movement number of the second comb pad yarn is:

[0030] GB1: 2-1 / 3-4 / 2-1 / 2-3 / 1-0 / 1-2 / 1-0 / 2-3 / / one through one empty polypropylene monofilament

[0031] GB2: 2-3 / 1-0 / 2-3 / 2-1 / 3-4 / 3-2 / 3-4 / 2-1 / / one through one empty polylactic acid monofilament

[0032] (2) Washing of patches: Gently rinse in cold water to remove surface impurities, and dry naturally at room temperature.

[0033] (3) Heat setting of the patch: the heat setting temperature is 130°C, and the heat setting time is 10 minutes.

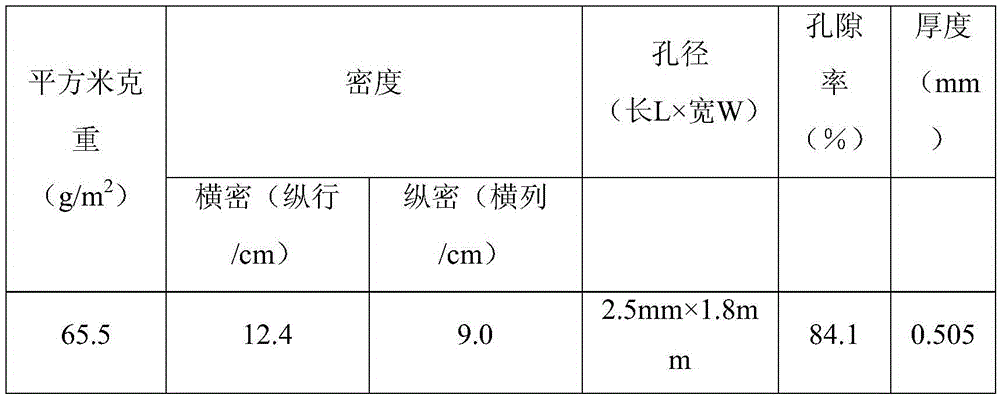

[0034] The polypropylene pelvic floor patch prepared by the above process, such as figure 1 shown. Its main structural parameters are shown in Table 1.

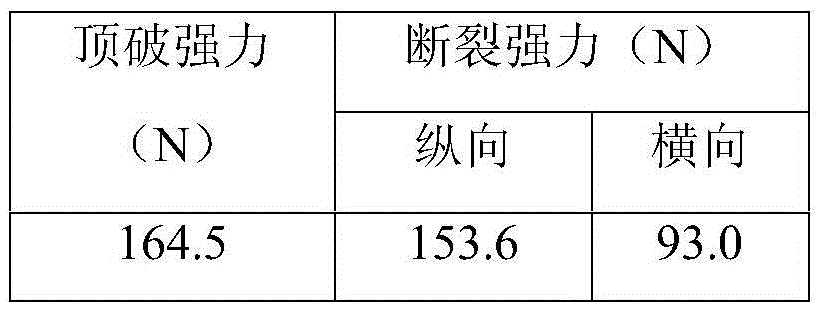

[0035] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com