Tobacco stem processing system and method

A processing system and processing method technology, applied in the field of reconstituted tobacco leaf processing, can solve the problems of insufficient swelling of fibers, difficulty in absorbing moisture, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

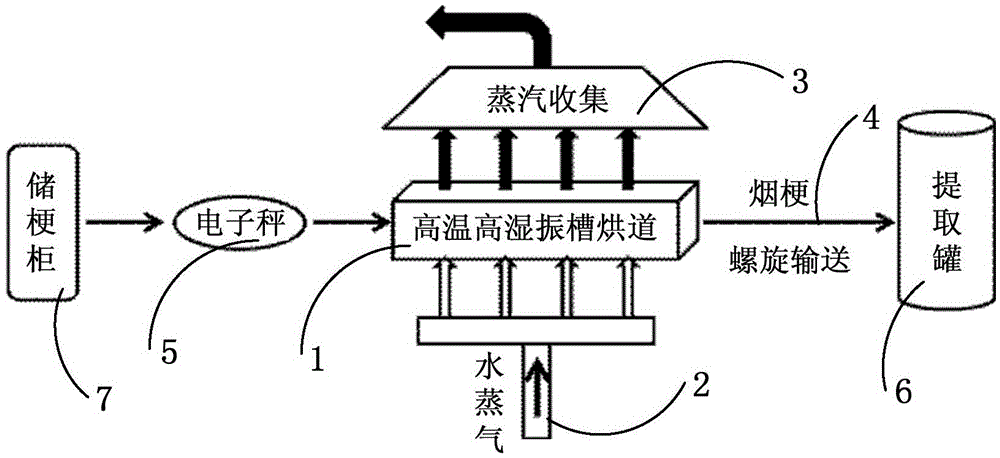

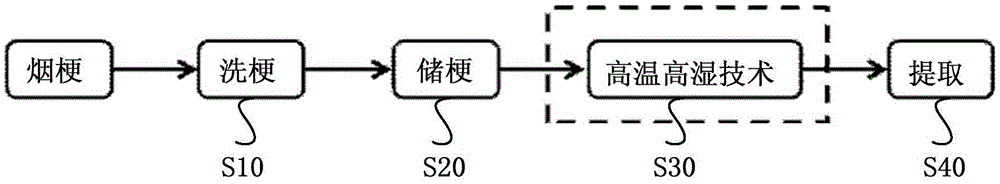

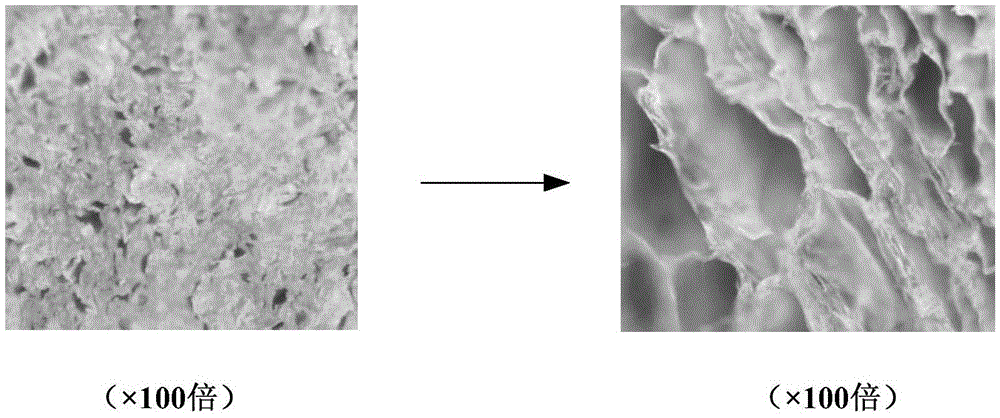

[0059] Example 1: Effects of High Temperature and High Humidity Treatment on the Microstructure and Sensory Quality of Tobacco Stems

[0060] Weigh the 2012 tobacco stems, 2013 tobacco stems, and 2014 tobacco stems in a mass ratio of 30:20:50, totaling 4000 kg, and mix them evenly. The mixed tobacco stems enter the storage cabinet after washing the stems, and then are sent to the high-temperature and high-humidity vibrating tank after being weighed by an electronic scale. After high-temperature and high-humidity treatment, it enters the extraction tank 6. Samples were taken before and after the high-temperature and high-humidity vibration tank, and the microstructure of the cross-section of the tobacco stem was observed with a laser confocal microscope, and the sensory evaluation of the samples was carried out.

[0061] 1 Using laser confocal microscope objective lens: TUPlanFluor10× / 0.30, DAPI light source

[0062] Microscopic observation was carried out on the above sample...

Embodiment 2

[0069] Example 2: Effect of High Temperature and High Humidity Treatment on Concentration Process Capability and Sensory Quality of Tobacco Stem Paste

[0070] Weigh the 2011 tobacco stems, 2012 tobacco stems, and 2014 tobacco stems in a mass ratio of 10:40:50, totaling 2500 kg, and mix them evenly. The mixed tobacco stems enter the storage cabinet after washing the stems, and then are sent to the high-temperature and high-humidity vibrating tank after being weighed by an electronic scale. After high-temperature and high-humidity treatment, it enters the extraction tank 6, and the extract enters the concentrator for concentration treatment. Follow-up sampling was carried out on the process capability control of the concentrated stem paste process, the change of the process capability of the solid content of the sample was detected, and the sensory evaluation was carried out on the sample.

[0071] (1) Based on the experimental basis of the reconstituted tobacco leaf productio...

Embodiment 3

[0078] Example 3: Effect of High Temperature and High Humidity Treatment on Fluctuation of Solid Content of Tobacco Stem Paste

[0079] Weigh the 2011 tobacco stems, 2013 tobacco stems, and 2014 tobacco stems in a mass ratio of 40:40:20, totaling 3000 kg, and mix them evenly. The mixed tobacco stems enter the storage cabinet after washing the stems, and then are sent to the high-temperature and high-humidity vibrating tank after being weighed by an electronic scale. After high-temperature and high-humidity treatment, it enters the extraction tank 6, and the extract enters the concentrator for concentration treatment. Sampling the concentrated stalk paste to measure the fluctuation of its solid content.

[0080] Based on the experimental basis of the reconstituted tobacco leaf production line, for 12 consecutive days, a sample of the production line stalk paste was taken every 8 hours, and the density and solid content of all samples were measured respectively. The solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com