Processing technology of low-caffeine, high-aroma and non-astringent tea

A low-caffeine, processing technology, applied in the directions of tea spice, pre-extraction tea treatment, tea reduction of alkali content, etc., can solve problems such as affecting the taste of tea leaves, reduce stimulation and influence on sleep, reduce production costs, and improve The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

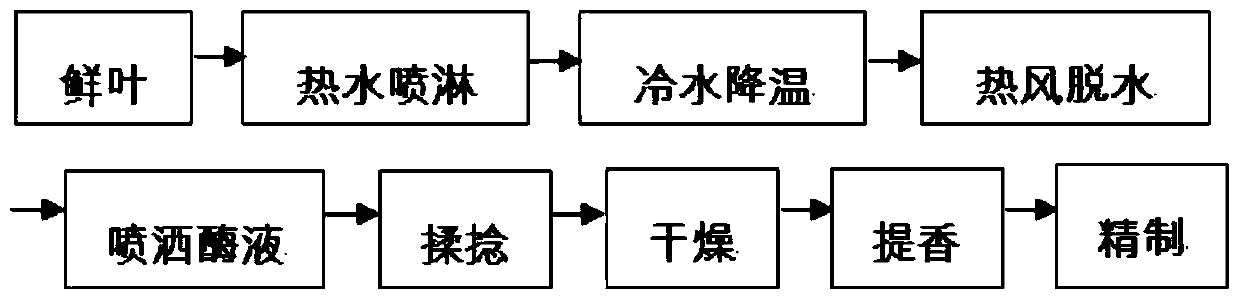

[0061] Such as figure 1 As shown, the processing technology of the low-caffeine high-scented and non-astringent mouthfeel tea described in the present embodiment comprises the following steps:

[0062] (1) Hot water spray: Take 1kg of freshly picked green tea leaves, and spray them with hot water at about 92°C without spreading them out. The spray flow rate of the hot water is 2.5L / min. Drenching for 2 minutes;

[0063] (2) Cooling with cold water: Spray the fresh tea leaves after the hot water spraying treatment with cold water immediately, the spraying cold water flow rate is 0.5L / min, carry out the spraying treatment for 3 minutes, and cool down until the temperature of the leaves drops to about 25°C;

[0064] (3) Hot air dehydration: place the cooled tea leaves in hot air dehydration equipment for hot air dehydration, control the hot air temperature to 200°C, and dry until the moisture content of the leaves is 45-50%;

[0065] (4) Spray enzyme liquid: take cellulase and ...

Embodiment 2

[0071] Such as figure 1 As shown, the processing technology of the low-caffeine high-scented and non-astringent mouthfeel tea described in the present embodiment comprises the following steps:

[0072] (1) Hot water spray: Take 1 kg of freshly picked green tea leaves, and spray them with hot water at about 100°C without spreading them. The spray flow rate of the hot water is 0.3L / min, Drenching for 5 minutes;

[0073] (2) Cooling with cold water: Spray the fresh tea leaves treated with hot water immediately with cold water at a flow rate of 0.5 L / min, spray for 1 min, and cool down until the temperature of the leaves drops to 35°C;

[0074] (3) Hot air dehydration: place the cooled tea leaves in hot air dehydration equipment for hot air dehydration, control the hot air temperature to 120°C, and bake until the moisture content of the leaves is 45-50%;

[0075] (4) Spray enzyme liquid: take cellulase, β-glucosidase, papain to make enzyme liquid, and according to the ratio of e...

Embodiment 3

[0081] Such as figure 1 As shown, the processing technology of the low-caffeine high-scented and non-astringent mouthfeel tea described in the present embodiment comprises the following steps:

[0082] (1) Hot water spray: Take 1 kg of freshly picked green tea leaves, and spray them with hot water at about 96°C without spreading them out. The spray flow rate of the hot water is 0.5L / min, Drenching for 3 minutes;

[0083] (2) Cooling with cold water: Spray the fresh tea leaves after the hot water spraying treatment with cold water immediately, the spraying cold water flow rate is 0.5L / min, carry out the spraying treatment for 2min, and cool down until the temperature of the leaves drops to 30°C;

[0084] (3) Hot air dehydration: place the cooled tea leaves in hot air dehydration equipment for hot air dehydration, control the hot air temperature to 150°C, and bake until the moisture content of the leaves is 45-50%;

[0085] (4) Spray enzyme liquid: take pectinase, tannase, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com