Method for improving solubility of concentrated protein powder by means of fatty acid combination or by removing calcium in casein micelle

A casein glue and milk protein concentration technology, applied in the field of milk powder processing, can solve the problems of poor rehydration, low MPC solubility index, etc., achieve easy preservation, improve storage stability and texture and other properties, and the process operation is green and simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] A kind of is with MPC485 as raw material, utilizes the method that ricinoleic acid combines calcium to improve MPC485 dissolubility, and its concrete processing steps are as follows:

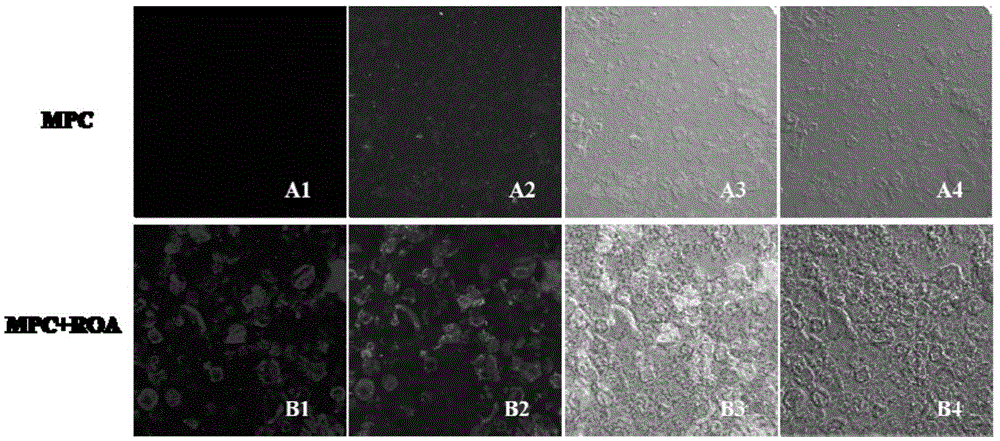

[0025] Example 1: Take 500g of commercial concentrated milk protein MPC485 and rehydrate, adjust the pH of the solution to 7.0, and then add 78.7g of ricinoleic acid and ultrapure water to a total mass of 3.6kg at 50°C in a constant temperature shaking water bath for 1 hour, stir well, and pre-homogenize After massaging for 2 minutes, homogenize continuously for 4 times in an ultra-high pressure homogenizer with a homogenization pressure of 28Mpa, and finally spray dry at 105°C / 65°C. In addition, MPC485 was prepared from a solution without ricinoleic acid as a control group. In order to ensure the repeatability of the process, each type of solution was paralleled once, and the microstructure of the two milk powders obtained was characterized by laser confocal images ( figure 1 ), where f...

Embodiment example 2

[0027] A method for improving the solubility of milk powder by using fresh milk as a raw material through decalcification of oleic acid, the specific process steps are as follows:

[0028] Take 1L of commercially available fresh milk as the raw material, adjust the pH of the solution to 7.0, add 5.8g of oleic acid in a constant temperature shaking water bath at 50°C for 1 hour, stir evenly, pre-homogenize for 2 minutes, and then homogenize continuously for 4 times in an ultra-high pressure homogenizer. The homogeneous pressure is 28Mpa, and it is finally spray-dried at 105°C / 65°C. In addition, the fresh solution without adding oleic acid was used as the control group, and the decalcification rate reached 24.4%.

Embodiment example 3

[0030] A method for improving the solubility of milk powder by using commercially available whole milk as a raw material and utilizing linoleic acid decalcification, the specific process steps are as follows:

[0031] Take 1L of commercially available fresh whole fat as raw material, adjust the pH of the solution to 7.0, add 35g of linoleic acid in a constant temperature shaking water bath at 50°C for 1 hour, stir evenly, pre-homogenize for 2 minutes, and then homogenize continuously for 4 times in an ultra-high pressure homogenizer , the homogeneous pressure is 28Mpa, and finally it is spray-dried at 105°C / 65°C. In addition, the fresh solution without adding linoleic acid was used as the control group, and the decalcification rate reached 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com