A kind of warm mix asphalt and preparation method thereof

A warm-mix asphalt and warm-mix agent technology, applied in building insulation materials, building components, climate change adaptation, etc., can solve the problem of reducing the viscosity or elongation of asphalt at 60°C, reducing the mixing temperature of asphalt mixture, and not giving a matrix Asphalt 135°C viscosity Asphalt viscosity and other problems, to improve the elongation of asphalt, the preparation process is simple, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

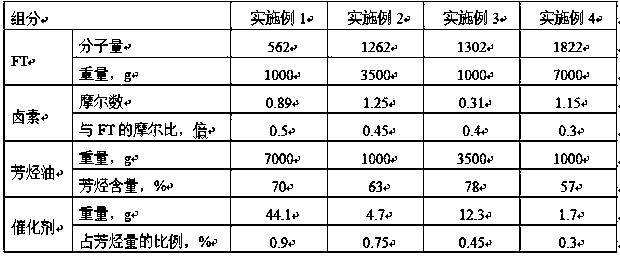

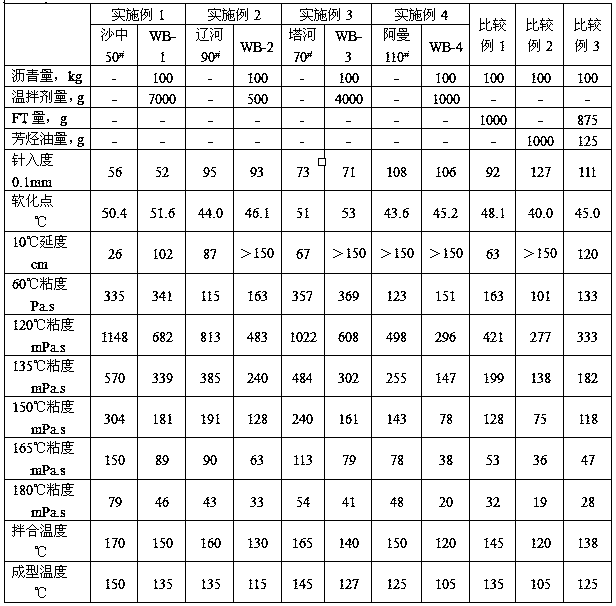

[0039] Put the FT with carbon number of 40, molecular weight of 562 and weight of 1000g obtained after coal gasification into a synthesis reaction into a closed container, heat to 250°C, introduce 0.89 moles of chlorine at this temperature, and stir for 60 minutes to obtain intermediate body; Weigh 7000g of the four-line extracted oil with an aromatics content of 70%, put it in another airtight container and heat it to 70°C, add 44.1g of anhydrous AlCl 3 , stirred for 45 min. Then spray the above-mentioned intermediate into the oil extracted from the four-line extraction in a state of stirring. After all the spraying, keep the temperature at 70°C, stir and react for 90 minutes, and obtain the special warm mixing agent used in the present invention. The distribution ratio of each group is shown in Table 1.

[0040] Weigh 7000g of the above-mentioned special warm mix agent, add it to Shazhong Crude Oil No. 50 solvent deoiled asphalt with a weight of 100 kg and a temperature of ...

Embodiment 2

[0042] The FT obtained by gasifying coal with a carbon number of 90, a molecular weight of 1262, and a weight of 3500g is placed in a closed container, heated to 370°C, and 1.16 moles of chlorine are introduced at this temperature, and stirred for 100 minutes to obtain intermediate body; Weigh 1000g of catalytic cracking oil slurry with an aromatic content of 63%, put it in another airtight container and heat it to 90°C, add 4.7g of anhydrous TiCl 4 , stirred for 35 min. Then, the above-mentioned intermediate is sprayed into the catalytic cracking oil slurry in the form of mist under stirring. After all the spraying is completed, the temperature is kept at 90°C, and the reaction is stirred for 160 minutes to obtain the special warm mixing agent used in the present invention. The distribution ratio of each group is shown in Table 1.

[0043] Weigh 500g of the above-mentioned special warm mix agent, add it to Liaohe Crude Oil No. 90 oxidized asphalt with a weight of 100 kg and ...

Embodiment 3

[0045] Put the FT obtained by the synthetic reaction of natural gas with a carbon number of 100, a molecular weight of 1302 and a weight of 1000g in an airtight container, heat it to 325°C, introduce 0.31 moles of fluorine at this temperature, stir for 120min, and obtain intermediate body; Weigh 3500g of phenolic refined extract oil with aromatics content of 78%, put it in another airtight container and heat it to 110°C, add 12.3g of anhydrous SbCl to it 3 , stirred for 40 min. Then spray the above-mentioned intermediate into the refined phenol extraction oil in the state of stirring. After spraying all the mixture, keep the temperature at 110°C and stir for 135 minutes to obtain the special warm mixing agent used in the present invention. The distribution ratio of each group is shown in Table 1.

[0046] Weigh 4000g of the above-mentioned special warm mix agent, add it to Tahe crude oil No. 70 blended asphalt with a weight of 100 kg and a temperature of 150°C, and stir for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com