Integrated interface-less solid electrolyte lithium ion battery and preparation methods thereof

A solid-state electrolyte and lithium-ion battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems such as poor contact tightness, low lithium-ion conductivity, and increased battery internal resistance. Achieve the effect of reducing the internal resistance of the battery, increasing the conductivity, and increasing the degree of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

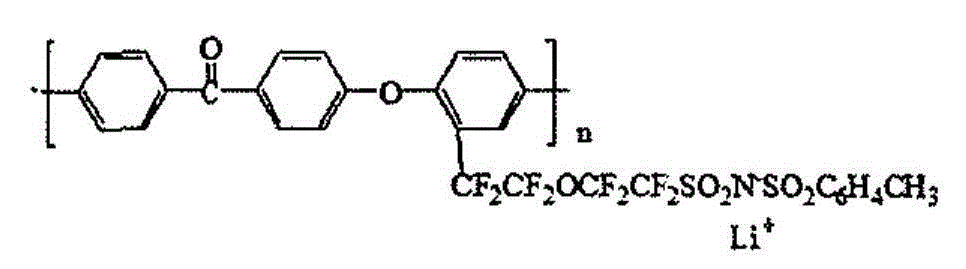

[0050] In this example, an integrated lithium-ion battery was prepared by a coating method. In the integrated non-interface solid electrolyte lithium-ion battery, the positive current collector is aluminum foil, and the positive active material layer on the positive current collector is made of LiFePO 4 , SuperP, and binder; the negative electrode current collector is copper foil, and the negative electrode active material layer on the negative electrode current collector is composed of graphite, SuperP, and binder; the solid electrolyte material and the binder material both contain fluorine in the side chain The polyaryl ether sulfone lithium salt of sulfonimide group, its structural formula is as follows:

[0051]

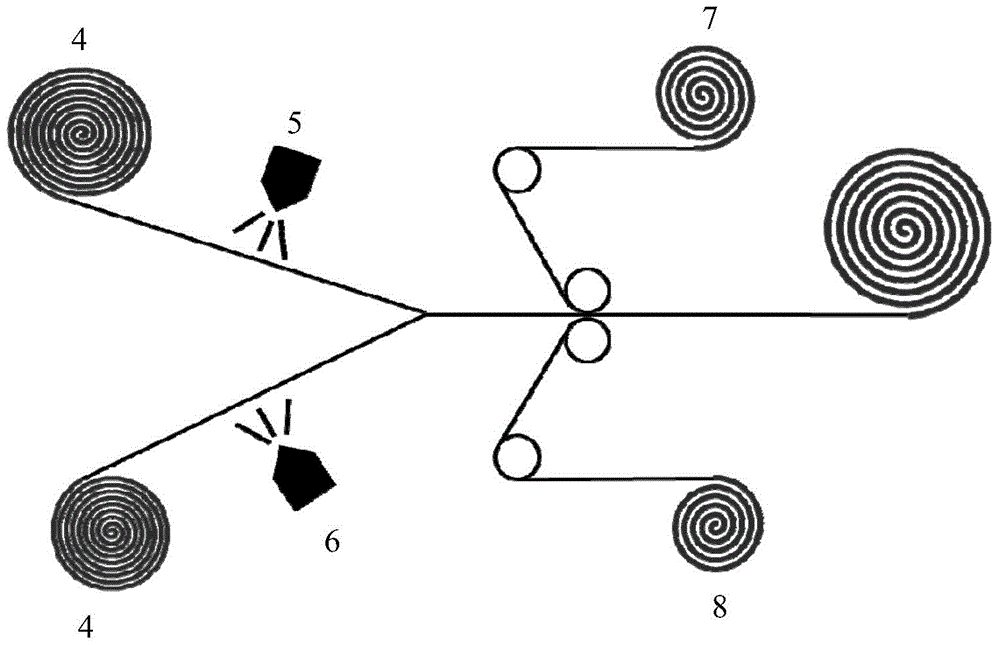

[0052] The preparation method of the integrated non-interface solid electrolyte lithium ion battery is as follows: figure 1 shown, including the following

[0053] step:

[0054] (1) Preparation of binder solution

[0055] Dissolve the polyarylethersulfone...

Embodiment 2

[0063] In this example, the preparation method of the integrated non-interface solid-state electrolyte lithium-ion battery is basically the same as in Example 1, except that the solid-state electrolyte material and the binder are both poly(5-sulfonyl chloride-3-oxa) Perfluorosulfonamide polymer lithium salt, wherein the thickness of the solid electrolyte membrane is still about 150 μm.

Embodiment 3

[0065] In this example, the preparation method of the integrated non-interface solid electrolyte lithium-ion battery is basically similar to Example 2, except that the binder material is a heterogeneous material but poly(5-sulfonyl chloride-3-oxa ) a mixture of perfluorosulfonamide polymer lithium salt and polyvinylidene fluoride (PVDF) in a mass ratio of 1:1.

[0066] The preparation method of the integrated non-interface solid electrolyte lithium ion battery is as follows: figure 1 shown, including the following steps:

[0067] (1) Preparation of binder solution

[0068] Poly(5-sulfonyl chloride-3-oxa) perfluorosulfonamide polymer lithium salt is mixed with polyvinylidene fluoride (PVDF) at a mass ratio of 1:1; the mixture is dissolved in N- In methylpyrrolidone, after fully stirring for 12 hours, a binder solution based on fluorine-containing sulfonimide-based polymer was prepared.

[0069] (2) Making positive and negative pole pieces

[0070] 80 parts by weight of pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com