Moisture-proof cable

A moisture-proof cable and wrapping technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of shortening the service life of cables, inconvenient transportation and wiring, and aggravated cable damage, so as to facilitate transportation, reduce maintenance work intensity, and save materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

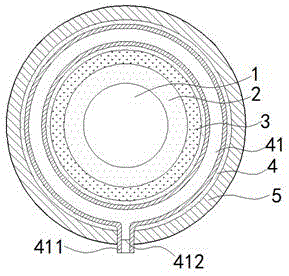

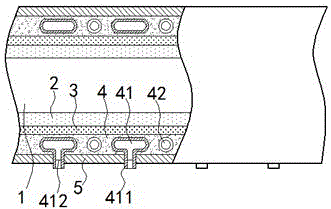

[0014] exist figure 1 , figure 2 In the shown embodiment, the moisture-proof cable includes a conductor core 1, and an insulating protection layer 2 is wrapped outside the conductor core 1; a blocking layer 3 is also wrapped outside the insulation protection layer 2, and the The barrier layer 3 is made of elastic material, and the outer peripheral wall of the barrier layer 3 is coated with non-stick water glue; the outside of the barrier layer 3 is wrapped with a moisture-proof tube 4, and the The exterior is wrapped with an outer sheath 5 with a water-proof function; the moisture-proof tube 4 is made of porous water-absorbing swelling material; Negative pressure tube 41 is arranged, capillary holes are provided on the tube wall of said negative pressure tube 41; There is also an air extraction valve 411 next to it, and the air extraction valve 411 stretches out from the outer sheath 5; the air extraction valve 411 is made of a transparent material, and a dipping Water dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com