Diamond compact and manufacturing method thereof

A technology of diamond composite sheet and manufacturing method, which is applied in the field of diamond composite sheet for drilling industry and its preparation, can solve problems such as cracks easily appearing on the interface of composite sheet, achieve the effects of reducing production cost, reducing the amount of diamond micropowder, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

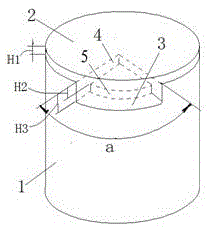

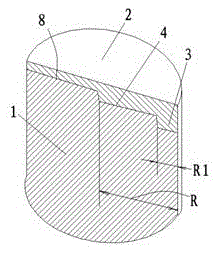

[0045] by attaching Figure 1-4 It can be seen that the present invention relates to a diamond composite sheet, comprising a cemented carbide substrate 1 and a diamond layer 2, and the diamond layer 2 is compounded on the cemented carbide substrate 1, which is characterized in that the diamond layer at the working edge part 3 of the diamond composite sheet The thickness is greater than the thickness of the diamond layer at the non-cutting edge, and the thickness of the diamond layer is only increased at the working edge part 3 of the diamond composite sheet. By locally increasing the thickness of the diamond layer, the overall performance of the diamond composite sheet can be changed, and the overall impact resistance can be improved. And reduce the wear of the mud on the substrate.

[0046] The diamond layer thickness of the working edge part 3 of the diamond composite sheet is greater than the diamond layer thickness of the non-edge part according to the degree of the diamon...

Embodiment 2

[0062] The basic structure of embodiment two is the same as that of embodiment one, except that the part of the bonding surface joined by the cemented carbide substrate and the diamond layer is made into a gap shape, which is to make the part participating in the cutting operation into a three-layer stepped shape (such as attached Figure 5 shown); in the cemented carbide substrate 201, a three-layer stepped notch groove 205 is made on the part 203 participating in the cutting operation, which are respectively the first stepped layer 204, the second stepped layer 207 and the third stepped layer 206; the diamond Layer 202 is made into a three-layer stepped protruding block by the part participating in the cutting operation, and the fan-shaped three-layer stepped protruding block of the diamond layer matches the fan-shaped three-layer stepped notch groove on the cemented carbide substrate; the surface thickness of the diamond layer is 0.5mm, the thickness of the first stepped la...

Embodiment 3

[0064] The basic structure of the third embodiment is the same as that of the first embodiment, except that the part 303 of the bonding surface where the cemented carbide substrate 301 and the diamond layer are bonded is made into a notch, and the part that participates in the cutting operation is made into a fan-shaped oblique block 304 (as attached Image 6 As shown); in the cemented carbide substrate 301, the fan-shaped oblique block gap groove is made on the part that participates in the cutting operation, and the fan-shaped oblique block protruding block is made on the part of the diamond layer 302 that participates in the cutting operation, and the fan-shaped oblique block of the diamond layer protrudes The blocks fit into the scalloped block notch grooves on the cemented carbide substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com