Double-tube type electromagnetic induction RH device and method for heating molten steel and removing inclusions

A technology of electromagnetic induction and inclusions, applied in the field of iron and steel metallurgy, can solve the problems that the removal rate is not particularly obvious, the purity of molten steel is affected, and the operation process is complicated, and the effect of low noise, high heating efficiency and uniform chemical composition can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

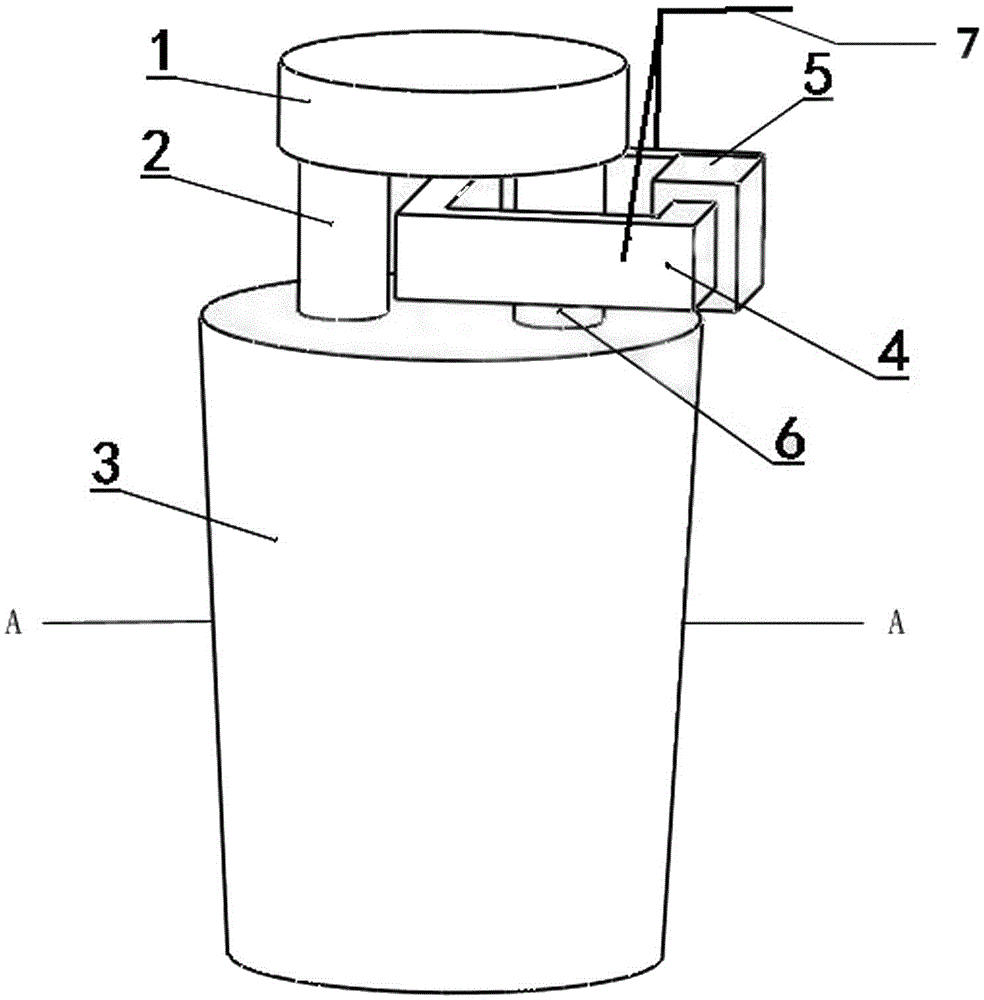

[0020] A double-tube electromagnetic induction heating RH device for heating molten steel and removing inclusions, such as Figure 1~2 As shown, it includes a ladle 3, a vacuum chamber 1, an ascending pipe 2, a descending pipe 6, an iron core 4 and an induction coil 5, wherein the bottom of the vacuum chamber 1 is provided with an ascending pipe 2 and a descending pipe 6, and the ascending pipe 2 and the descending pipe 6 are The port communicates with the ladle 3, the iron core 4 is a solid square structure, and is arranged around the riser 2 or the downcomer 6, the coil 5 is wound on the iron core part outside the downcomer 6, and the axis of the coil 5 is in line with the axis of the downcomer 6 Keep it vertical.

[0021] The iron core 4 is provided with a support rod 7, which is connected with an external bracket and used for fixing the iron core....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com