Cryogenic air-separation superconducting magnetic separator, separating device and separating method

A low-temperature air separation and superconducting magnetic technology, which is applied in the fields of separation devices, low-temperature air separation and superconducting magnetic separators, can solve the problems of low product purity and achieve the effects of high product purity, high gradient and increased magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

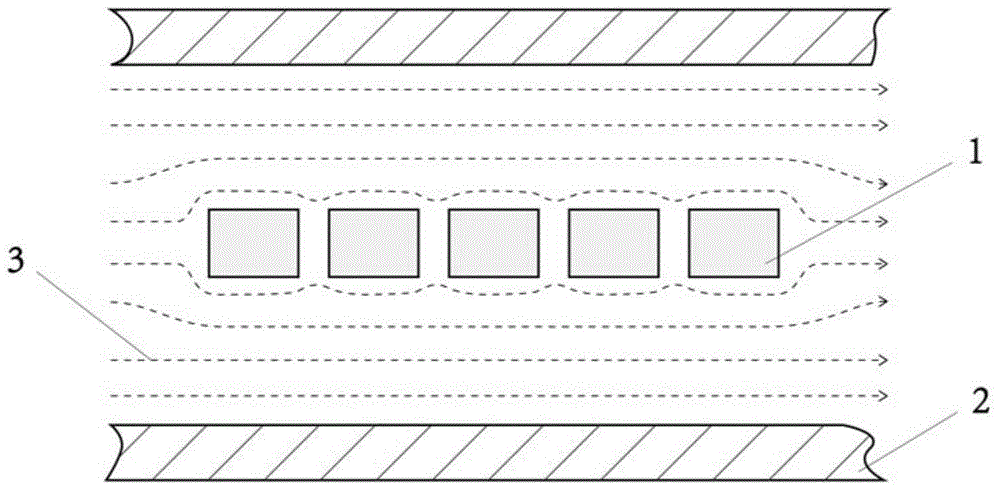

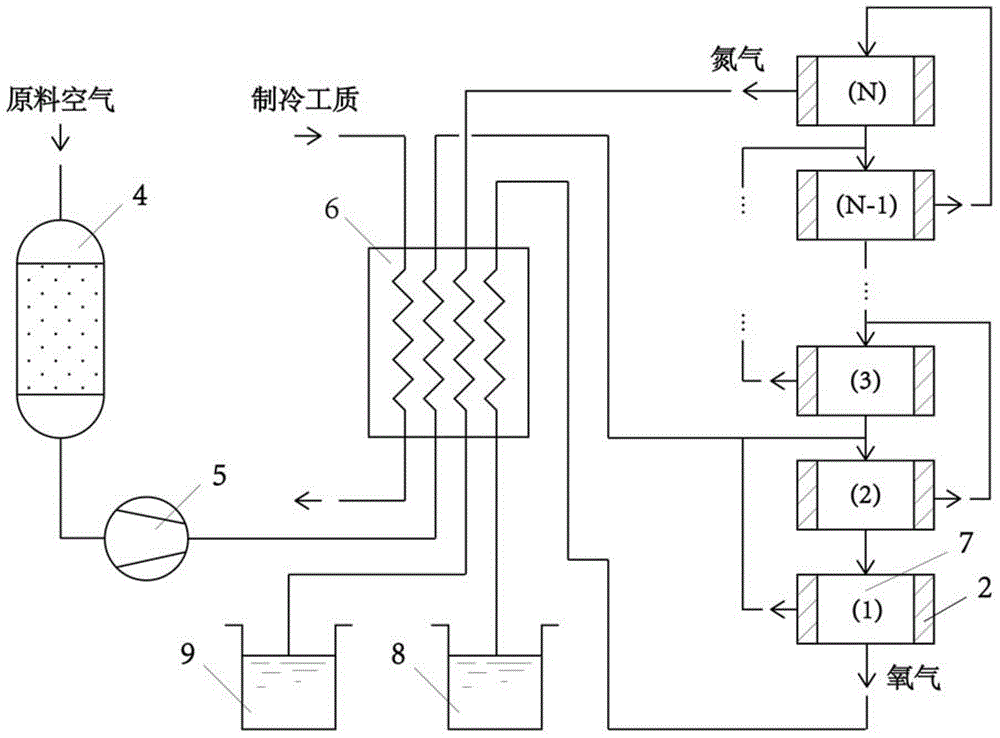

[0042] A method for low-temperature air separation using the superconducting Meissner effect, including allowing liquid or supercritical air to flow over the surface of a superconducting film. There are through micropores in the superconducting film, and a high-gradient magnetic field at the edge of the micropores An opposing force is provided for the oxygen molecules so that the fluid passing through the membrane is nitrogen and the trapped fluid is oxygen.

[0043] In the above method, the high gradient magnetic field at the edge of the micropore of the superconducting thin film can be provided by an external magnetic field. like figure 1 As shown, the superconducting film 1 is placed in the strong magnetic field provided by the superconducting magnet 2, and the film in the superconducting state will produce the Meissner effect under the external magnetic field, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com