Purification of organic compounds by surfactant mediated preparative HPLC

A technology for surfactants and organic compounds, applied in the field of purification of organic compounds, can solve the problems of increased purified products, expensive and affordable column hardware, laborious development, etc., to achieve reduced waste treatment, low equipment scale, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

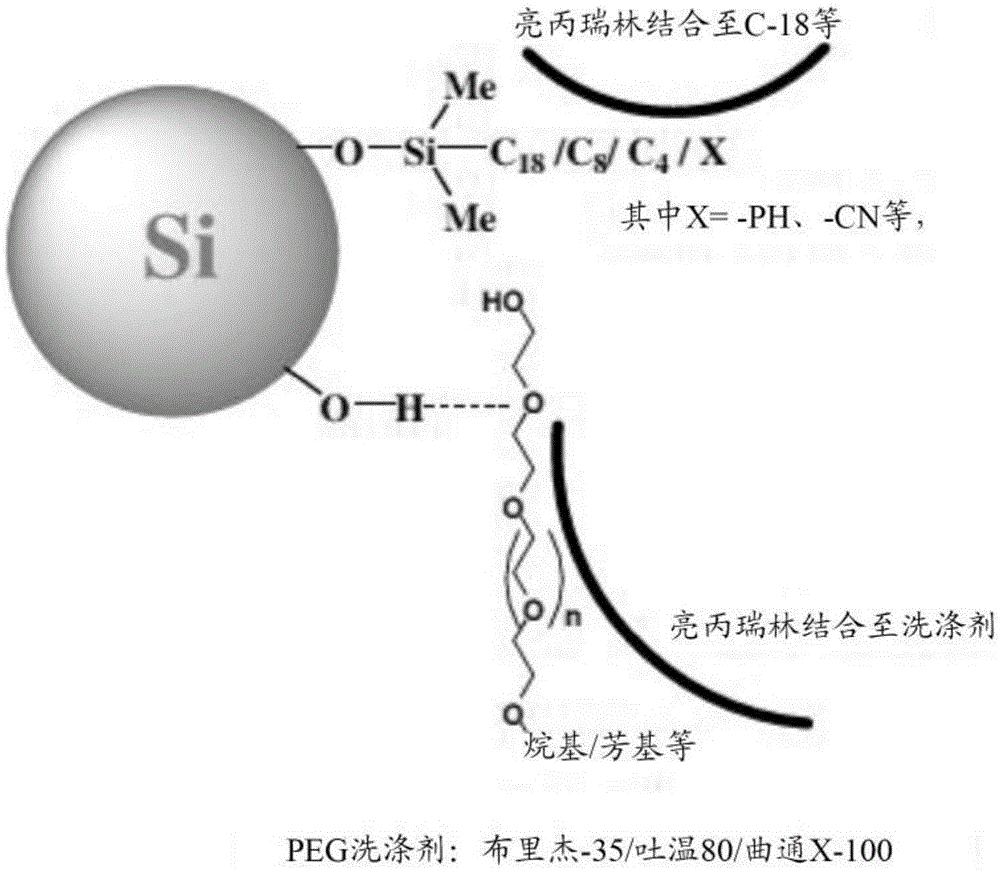

Method used

Image

Examples

Embodiment -1

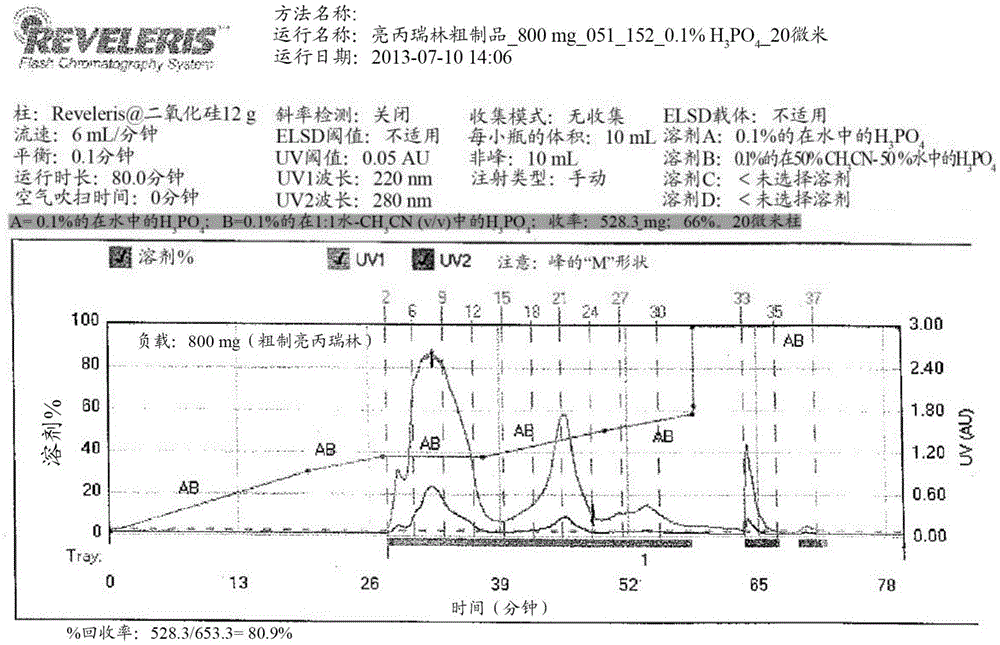

[0151] Example-1: Prep-RP-HPLC of Leuprolide Acetate Using Triton X-100 as Additional Stationary Phase and Aqueous Phosphate Buffer:

[0152] C-18 reverse phase column (RevelerisC-18, 12g, 40μ, Pore size) was saturated with Triton X-100 (12 g dissolved in 500 mL water). Excess unbound surfactant was washed with 90% aqueous acetonitrile containing 0.1% trifluoroacetic acid to remove unbound surfactant. Next, the column was equilibrated with 5 column volumes (CV) of 0.1% phosphoric acid in water (buffer A). Crude leuprolide (800 mg, net weight by Edelhoch method) dissolved in buffer A was loaded onto the column. The column was washed with 5 CV's of buffer A. Analytical RP-HPLC analysis of the "flow through" eluate revealed the absence of leuprolide. When this proceeding step was omitted, premature elution of crude API was observed because excess surfactant was present at a concentration above its critical micelle concentration. Next, start the gradient elution process. ...

Embodiment 2

[0154] Example 2: Prep-RP-HPLC of Leuprolide Acetate Using Triton X-100 as Additional Stationary Phase and 0.1 mM Cetyltrimethylammonium Bromide Buffer:

[0155] A Reveleris silica derivatized C-18 column (12 g of stationary phase, 40 micron diameter particles, and 60 Angstrom pore size) was chosen and saturated with 12 g of Triton X-100 dissolved in water.

[0156] Excess unbound surfactant was removed by washing with 90% aqueous acetonitrile containing 0.1% trifluoroacetic acid. When this step was omitted, premature elution of crude API was observed because excess surfactant was present at a concentration above its critical micelle concentration.

[0157] Next, the crude API was loaded (81.7% leuprolide at 800 mg, corrected weight of leuprolide was 653.3 mg) and washed with 5 CVs of buffer A (0.1 mM cetyl bromide in water trimethylammonium and 0.1 mM sodium bicarbonate) to wash the column. Analytical RP-HPLC analysis of the "flow through" eluate revealed the absence of leu...

Embodiment 3

[0160] Example 3: Prep-RP-HPLC of Leuprolide Acetate Using Tween 80 as Additional Stationary Phase and 0.1 mM Cetyltrimethylammonium Bromide Buffer:

[0161] A Reveleris silica derivatized C-18 column (12 g of stationary phase, 40 micron diameter particles, and 60 Angstrom pore size) was selected and saturated with 12 g of Tween-80 dissolved in water.

[0162] Excess unbound surfactant was removed by washing with 90% aqueous acetonitrile containing 0.1% trifluoroacetic acid. When this step was omitted, premature elution of crude API was observed because excess surfactant was present at a concentration above its critical micelle concentration.

[0163] Next, the crude API was loaded (81.7% leuprolide at 800 mg, corrected weight of leuprolide was 653.3 mg) and washed with 5 CVs of buffer A (0.1 mM cetyl bromide in water trimethylammonium and 0.1 mM sodium bicarbonate) to wash the column. Analytical RP-HPLC analysis of the "flow through" eluate revealed the absence of leuprolid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com