Non-packaged LED flashing light, driving chip thereof, and manufacturing method

A technology for driving chips and flashing lights, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increased leakage current of driving chips, and achieve the effect of solving the increase of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

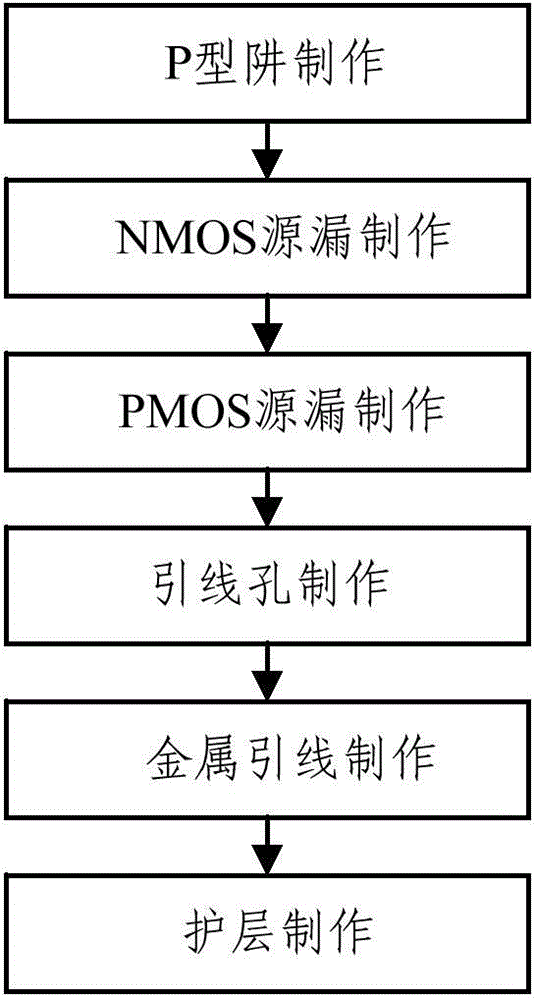

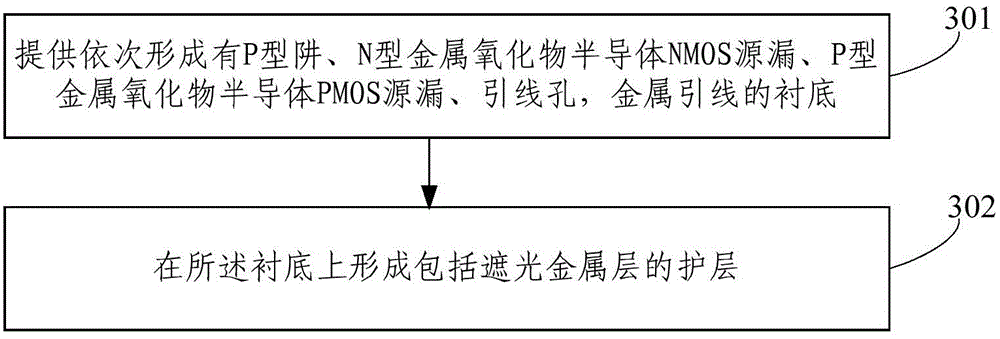

[0034] image 3 It shows a schematic flow chart of the manufacturing method of the driving chip of the unpackaged LED flashlight provided by the first embodiment of the present invention, as shown in figure 1 As shown, the manufacturing method of the driver chip of the unpackaged LED flashlight of this embodiment is as follows.

[0035] 301. Provide a substrate on which a P-type well, an N-type metal oxide semiconductor NMOS source and drain, a P-type metal oxide semiconductor PMOS source and drain, lead holes, and metal leads are sequentially formed.

[0036] It can be understood that the method of sequentially forming a P-type well, NMOS source and drain, PMOS source and drain, lead holes, and metal leads in this step is the same as figure 1 The corresponding steps in the shown prior art are the same, and the details thereof will not be repeated here.

[0037] 302. Form a protective layer including a light-shielding metal layer on the substrate.

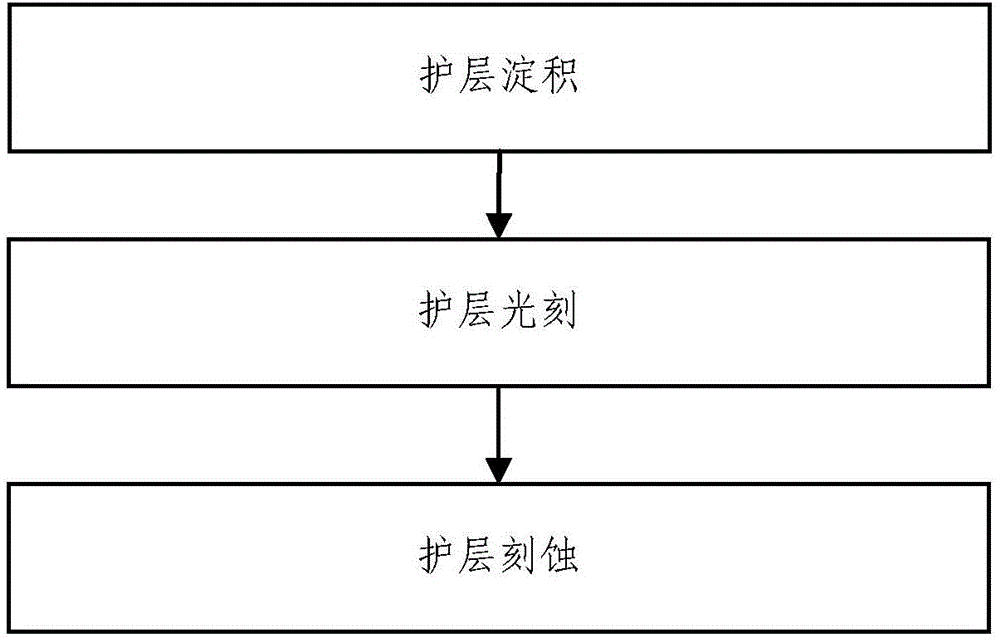

[0038] Preferably, the m...

no. 2 example

[0057] Figure 4 It shows a schematic flow diagram of the manufacturing method of the driving chip of the unpackaged LED flash lamp provided by the second embodiment of the present invention, as shown in Figure 4 As shown, the manufacturing method of the driver chip of the unpackaged LED flashlight of this embodiment is as follows.

[0058] 401. Provide a substrate on which a P-type well, an NMOS source and drain, a PMOS source and drain, a lead hole, and a metal lead are sequentially formed.

[0059] It can be understood that the method of sequentially forming a P-type well, NMOS source and drain, PMOS source and drain, lead holes, and metal leads in this step is the same as figure 1 The corresponding steps in the shown prior art are the same, and the details thereof will not be repeated here.

[0060] 402. Form a protective film on the substrate.

[0061] 403. Form a light-shielding metal layer film on the protective film.

[0062] In specific applications, this step ca...

no. 3 example

[0074] The driver chip for an unpackaged LED flashlight provided by the third embodiment of the present invention includes: a P-type well, an NMOS source and drain, a PMOS source and drain, lead holes, metal leads and a protective layer, and the protective layer includes a light-shielding metal layer.

[0075] Preferably, the material of the light-shielding metal layer in this embodiment may be aluminum, but this embodiment does not limit it, it is only for illustration and can be selected according to actual needs.

[0076] The driver chip of the non-encapsulated LED flashing lamp of the present embodiment adds a layer of light-shielding metal layer on the protective layer of the driver chip in the prior art. Due to the reflective effect of the metal, after adding the light-shielding metal layer, both can not It affects the appearance and brightness of the terminal product, and can effectively solve the problem of increased leakage current of the driver chip caused by light. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com