Preparation method of flake silver graphite electrical contact material

A technology of electric contact material, silver graphite, applied in circuits, electric switches, electrical components, etc., can solve problems such as direct contact with brittle phase graphite, achieve excellent mechanical and physical properties and processing properties, and the preparation method is simple and reduces direct contact. The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

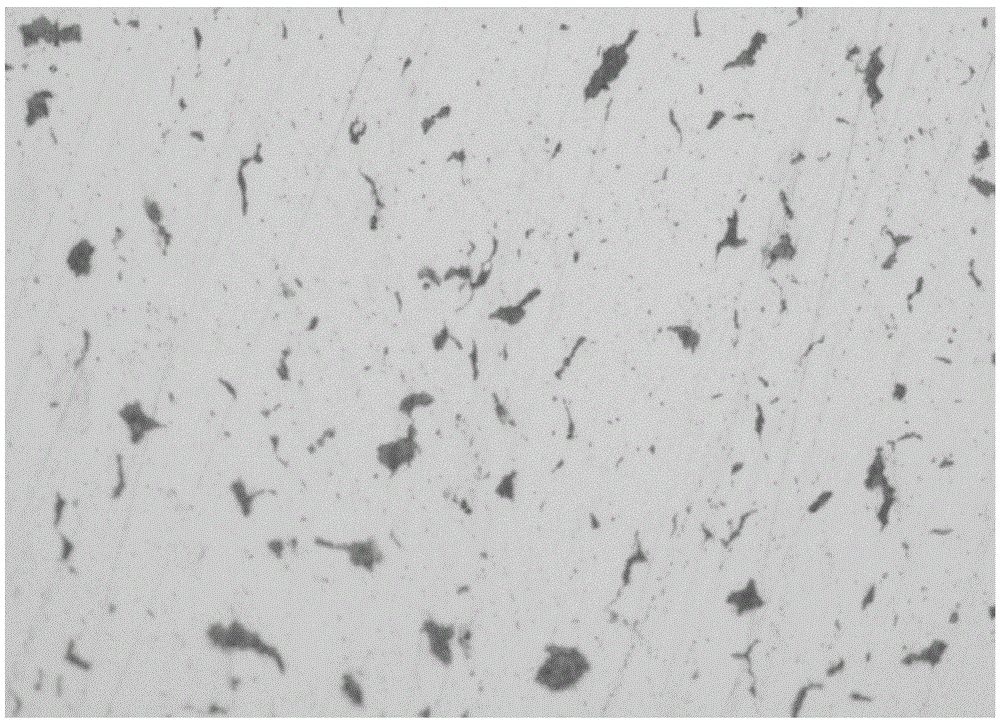

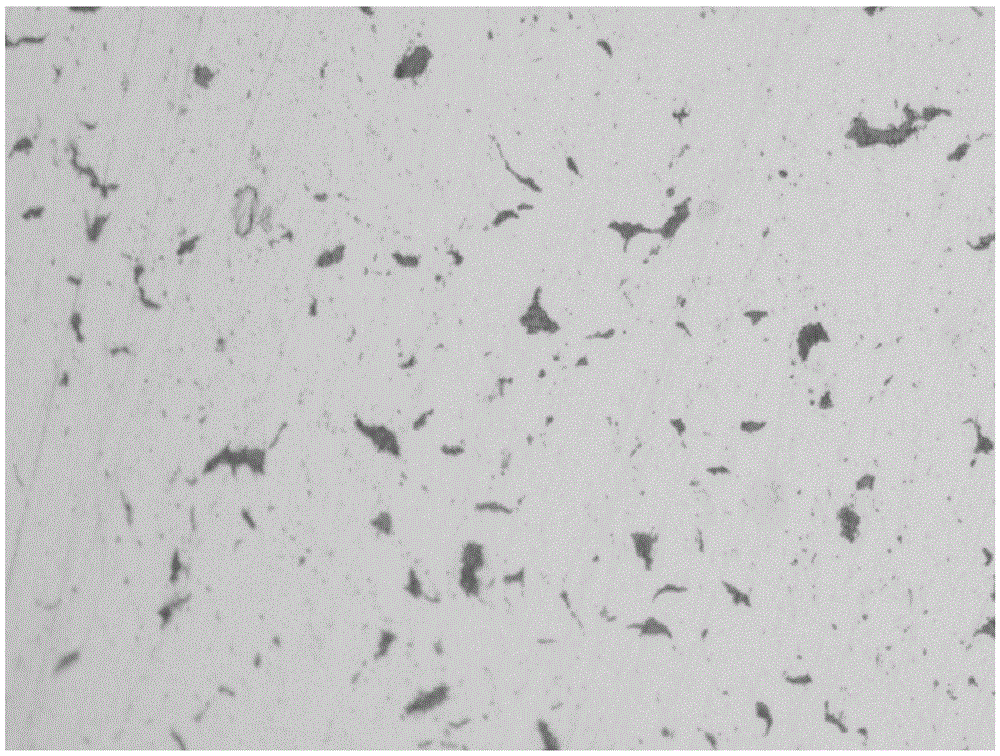

Image

Examples

Embodiment 1

[0028] 1) First calculate the required silver carbonate (Ag 2 CO 3 ) powder and graphite powder (C) consumption, take silver carbonate powder (average particle size is 6 μ m) 12.65kg, graphite powder (average particle size is 5 μ m) 0.1kg, standby;

[0029] 2) above-mentioned silver carbonate powder and graphite powder are carried out powder mixing on double-cone mixer, rotating speed 25r / min, time 2h, obtain silver carbonate graphite (Ag 2 CO 3 C) mixed powder;

[0030] 3) the silver carbonate graphite mixed powder after the above-mentioned mixed powder is molded on an isostatic press, and the molding pressure is 120MPa, and the silver carbonate graphite blank ingot after molding is placed in vacuum with 150 ℃ of temperature roasting 4h, obtains silver graphite ( AgC) ingot;

[0031] 4) the silver graphite ingot that above-mentioned roasting obtains is placed in hydrogen (H 2 ) sintering at 880°C for 8 hours in an atmosphere;

[0032] 5) decarburizing the above-mentione...

Embodiment 2

[0036] 1) First calculate the required silver carbonate (Ag 2 CO 3 ) and graphite powder (C) consumption, take silver carbonate powder (average particle size is 6 μ m) 12.01kg, graphite powder (average particle size is 5 μ m) 0.6kg, standby;

[0037] 2) above-mentioned silver carbonate powder and graphite powder are carried out powder mixing on double-cone mixer, rotating speed 25r / min, time 2h, obtain silver carbonate graphite (Ag 2 CO 3 C) mixed powder;

[0038] 3) the silver carbonate graphite mixed powder after the above-mentioned mixed powder is molded on an isostatic press, and the molding pressure is 150MPa, and the silver carbonate graphite billet after the molding is placed in vacuum with 250 ℃ of temperature roasting 4h, obtains silver graphite ( AgC) ingot;

[0039] 4) the silver graphite ingot that above-mentioned roasting obtains is placed in hydrogen (H 2 ) sintering at 920°C for 4 hours in an atmosphere;

[0040] 5) Decarburizing the above-mentioned sinter...

Embodiment 3

[0044] 1) First calculate the required silver carbonate (Ag 2 CO 3 ) and graphite powder (C) consumption, take silver carbonate powder (average particle size is 6 μ m) 12.14kg, graphite powder (average particle size is 5 μ m) 0.5kg, standby;

[0045] 2) above-mentioned silver carbonate powder and graphite powder are carried out powder mixing on double-cone mixer, rotating speed 40r / min, time 2h, obtain silver carbonate graphite (Ag 2 CO 3 C) mixed powder;

[0046] 3) the silver carbonate graphite mixed powder after the above-mentioned powder mixing is formed on an isostatic press, and the molding pressure is 100MPa, and the silver carbonate graphite blank ingot after forming is placed in vacuum with 280 ℃ of temperature roasting 2h, obtains silver graphite ( AgC) ingot;

[0047] 4) the silver graphite ingot that above-mentioned roasting obtains is placed in hydrogen (H 2 ) sintering at 900°C for 5 hours in an atmosphere;

[0048] 5) Decarburizing the above-mentioned sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com