An equivalent method for cross-scale thermal analysis of fiber-toughened composites with multiple criteria

A composite material and fiber toughening technology, applied in the effective field, can solve the problems such as the inability to fully reflect the physical properties and dispersion of CMC materials, the difficulty of obtaining a single type of RVE, and the lack of scholars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The multi-criteria fiber toughened composite material cross-scale thermal analysis equivalent method of the present invention comprises the following steps:

[0040] Step 1: Establish a representative unit (PRVE) with randomly distributed reinforcement phases for the internal structure of the composite material, and the side length of the unit is 20 times the diameter of the fiber reinforcement phase;

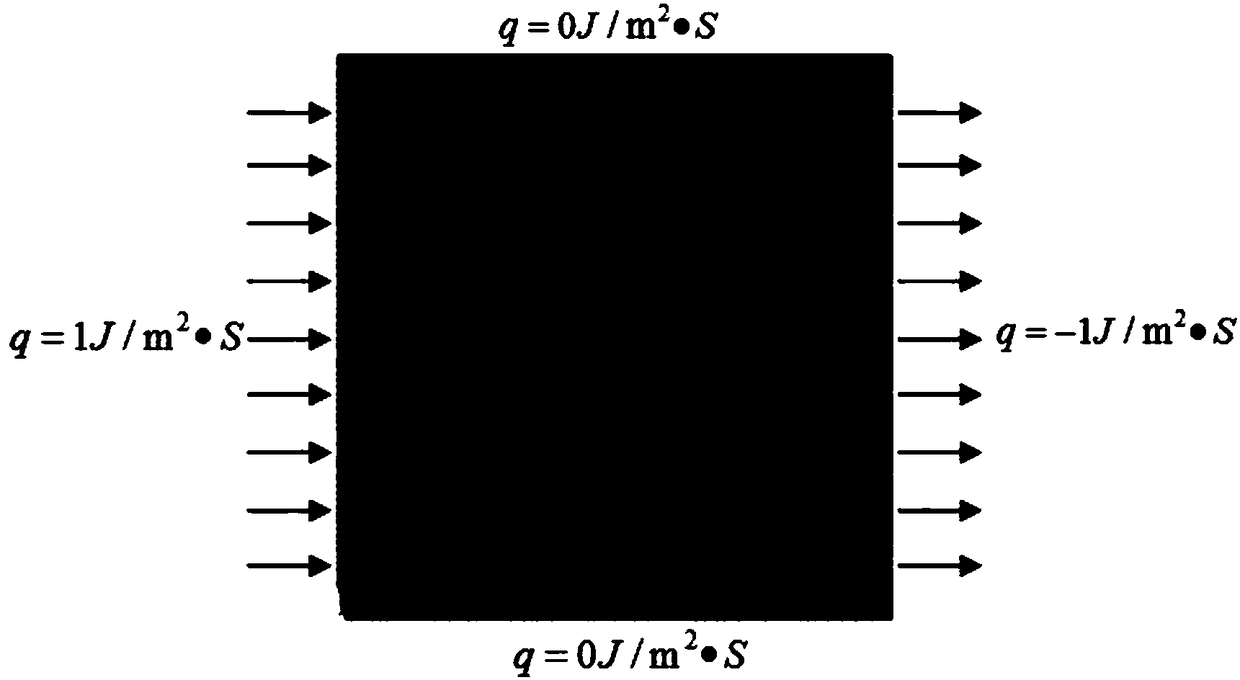

[0041] Step 2: Apply constant heat flow boundary conditions on the left and right sides of the PRVE, and apply adiabatic boundaries on the upper and lower sides;

[0042] Step 3: Use the finite element method to calculate the temperature field distribution of the unit, and obtain the corresponding material temperature gradient field, heat flux density field, and equivalent thermal conductivity through post-processing calculations;

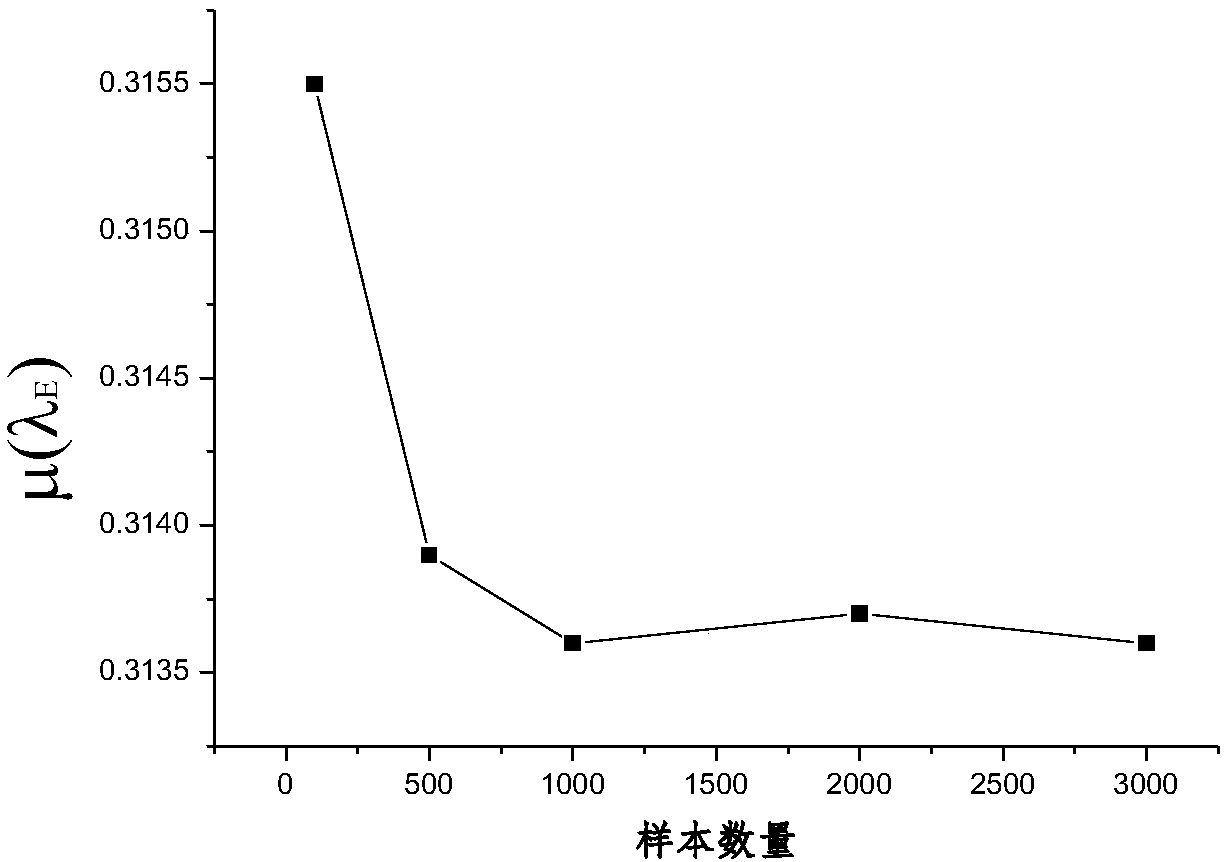

[0043] Step 4: Randomly generate representative units multiple times and use the finite element method to calculate to obtain the statistica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com