Measuring mechanism of resistance distribution in model test of ship jet drag reduction

A model test, resistance distribution technology, applied in ship construction, ship design, ship components, etc., can solve the problems of large difference, affecting the accuracy of test volume, gas escape and rapid diffusion, etc., to increase stability and improve measurement. Accuracy and reliability, the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

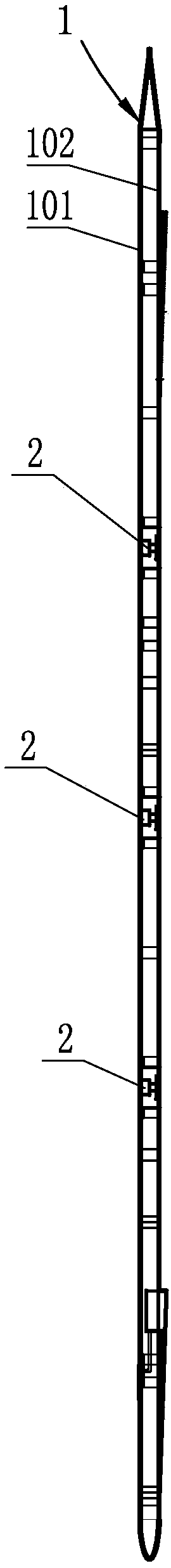

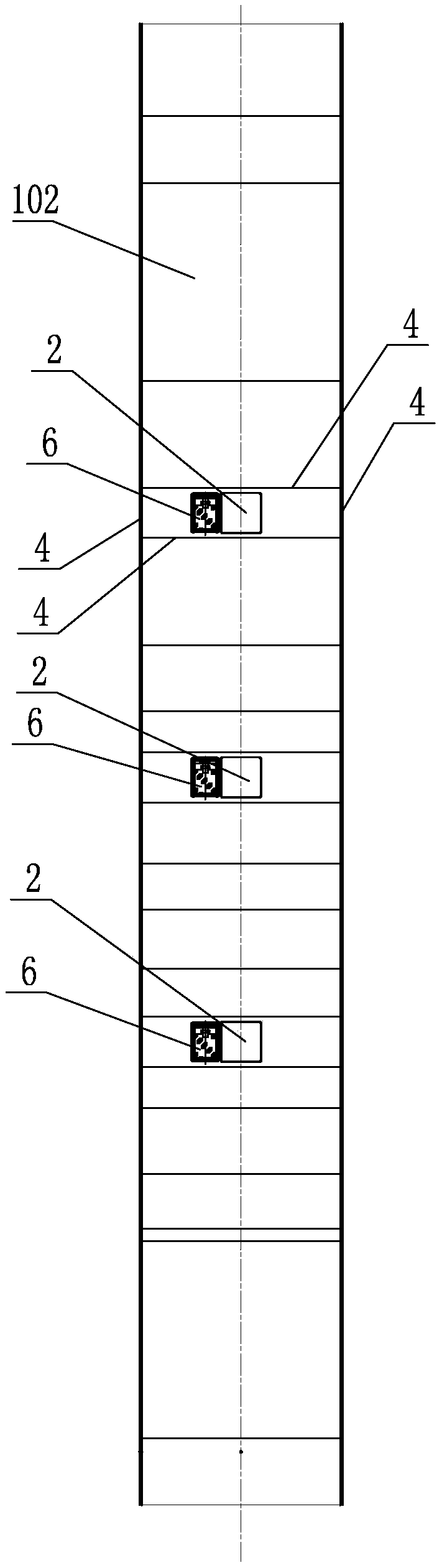

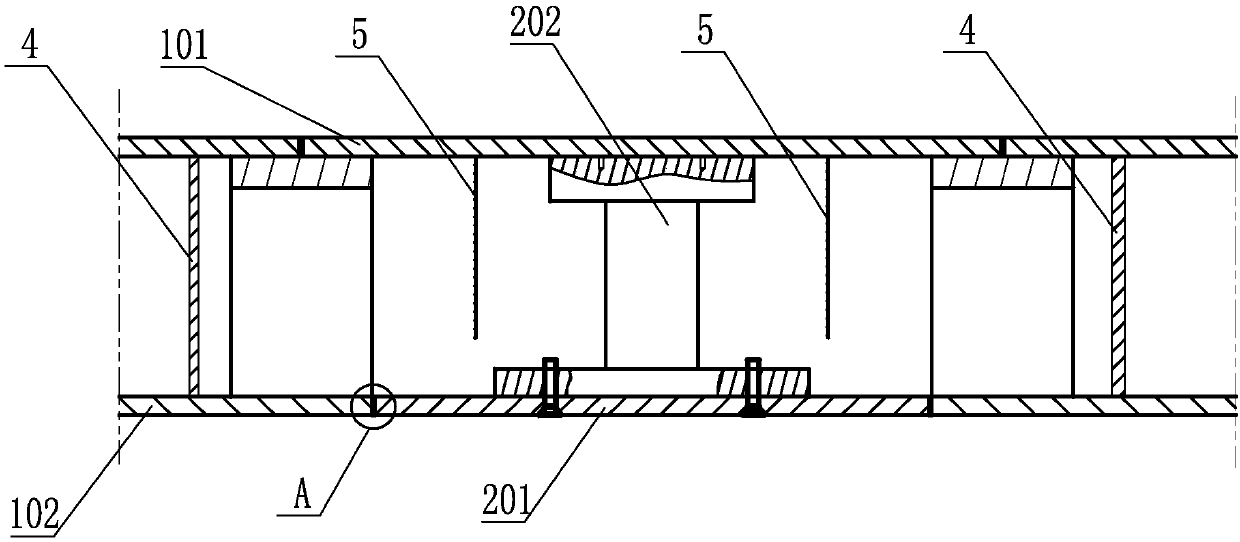

[0031] See figure 1 , figure 2 The resistance distribution measuring mechanism in the ship air jet drag reduction model test of the present invention includes at least three force-measuring units 2 arranged at intervals along the longitudinal direction of the model to be tested 1, and all force-measuring units 2 are distributed at least at the head of the model to be tested 1 in the longitudinal direction. Parts, middles and tails; see image 3 , Figure 4 , the force-measuring unit 2 includes a force-measuring plate 201 and a force-measuring sensor 202 affixed to the top of the force-measuring plate 201. 101 is fixed, and the lower plate 102 of the model to be tested 1 is provided with a through installation groove, the force measuring plate 201 is suspended in the installation groove, and there is an air gap around the force measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com