Squeezing type juicer

A juicer and extrusion technology, applied in the field of juicer, can solve the problems of high installation requirements, easy failure, complex structure, etc., and achieve the effects of convenient positioning, reduced failure rate, and smooth slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

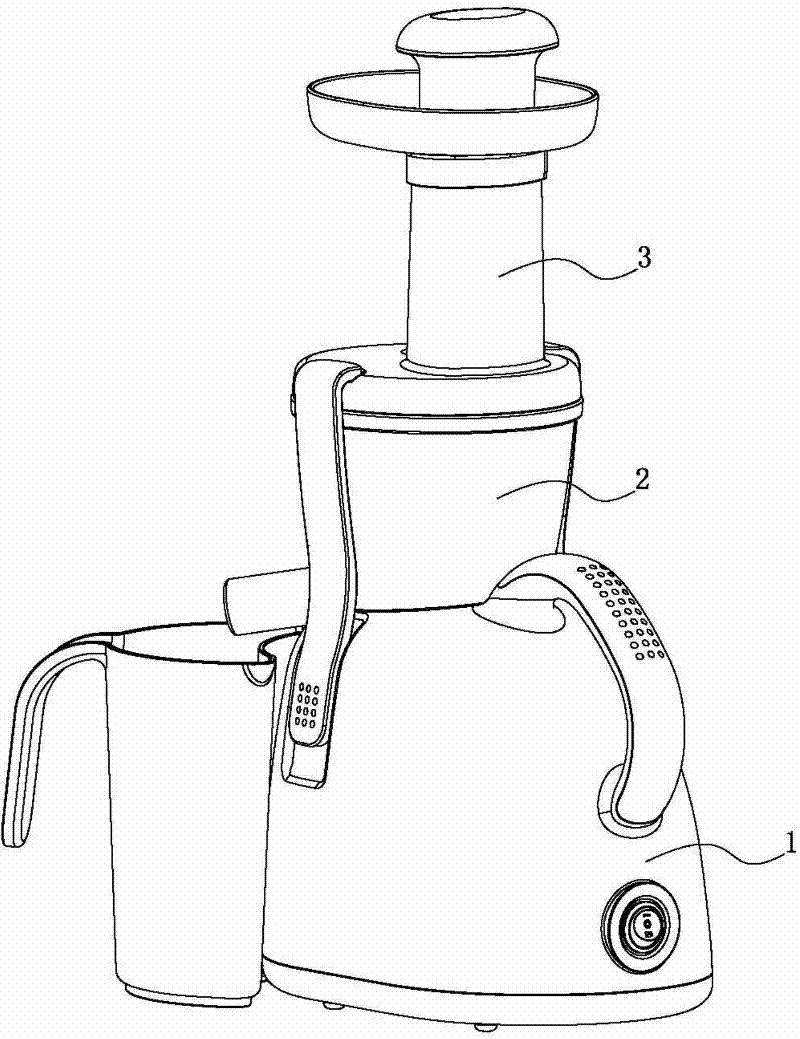

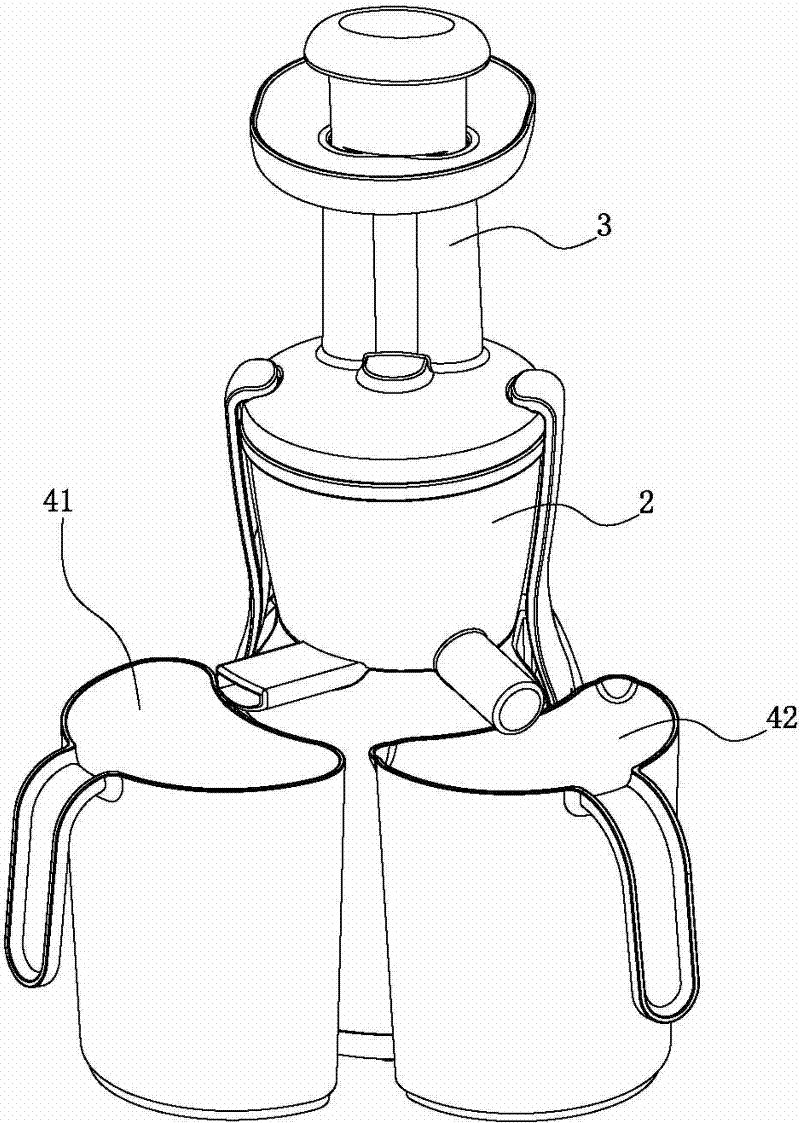

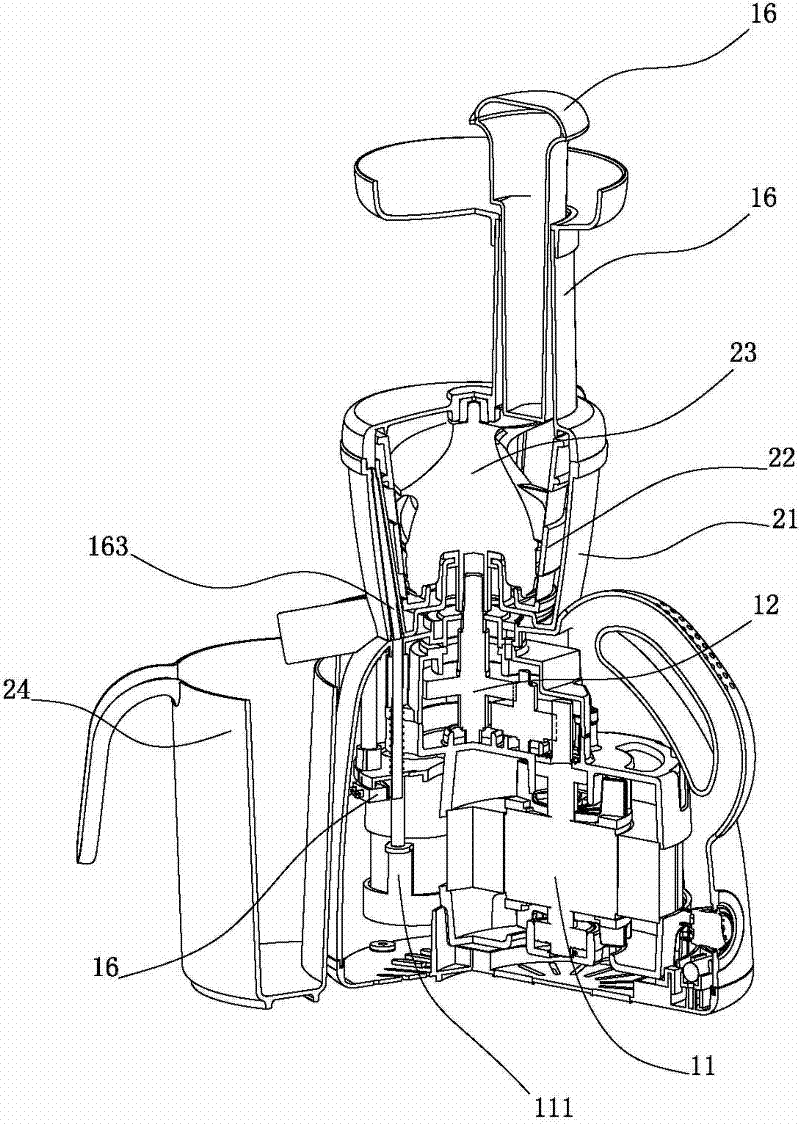

[0064] see Figure 1 to Figure 6 , an embodiment of a squeeze juice extractor provided in the present invention includes a base 1, a squeeze assembly 2 and a feed assembly 3, the base 1 is provided with a driving part 11, and the base 1 is provided with a driving shaft 12, the driving part 11 drives the driving shaft 12 to rotate; the extruding assembly 2 is installed on the base 1; the feeding assembly 3 is fastened to the extruding assembly 2 on.

[0065] see Figure 1 to Figure 6 , Figure 8 to Figure 23 , the extrusion assembly 2 includes a cup body 21, a mesh barrel 22 fixedly installed in the cup body 21 and a screw rod 23 located in the mesh barrel 22, the cup body 21 is provided with a juice outlet 24 and a slag discharge channel 25, the screw 23 is connected to the drive shaft 12, an extrusion space is formed between the mesh barrel 22 and the screw 23, and the bottom of the cup body 21 is formed with a juice collecting ring Groove 211, the juice collecting annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com