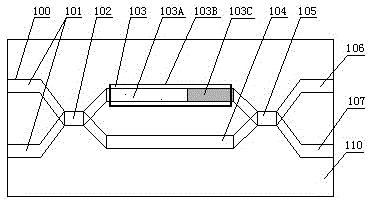

Optical switch based on plane waveguide and manufacturing method thereof

A technology of a planar waveguide and a manufacturing method, which is applied in the field of optical fiber communication equipment, can solve the problems of crosstalk between different waveguide branches, reduced device performance, inconsistent phase difference, etc., and achieves the effect of compact structure, small volume, and easy system integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] 1. Determine the core length of the main waveguide 103 and the branch waveguide 104: Calculate the fiber core length according to the selected material, if the first waveguide branch 103A of the main waveguide 103 and the fused silica material of the branch waveguide 104 have a refractive index n1=n3=1.445 , the thermo-optic coefficients at 1310nm and 1550nm are both small A1=A3=0.86*10^-5, the chiral azo polymer refractive index of the second waveguide branch 103C of the main waveguide 103 is material n2=1.479, The thermo-optic coefficients A2 at 1310nm and 1550nm are -10.8*10^-4 and -11.23*10^-4 respectively. Set the temperature rise of the thermal switch to ?T2=50 degrees, the length of the heated polymer waveguide 104 is L2, and the length of the waveguide 103 is L1; in order to realize the half-wavelength phase deviation, formula (1) should be satisfied:

[0057] L2*50*-11.23*10^-4+L1*50*0.86*10^-5=-1550 / 2(4)

[0058] At the same time, in order to achieve the stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com