Method for preparing gold nanorod material through reduction of hydroquinone under double surfactants

A dual-surfactant, hydroquinone technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems affecting the monodispersity and practicability of products, and many impurities, etc. Achieve the effect of monodispersity and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

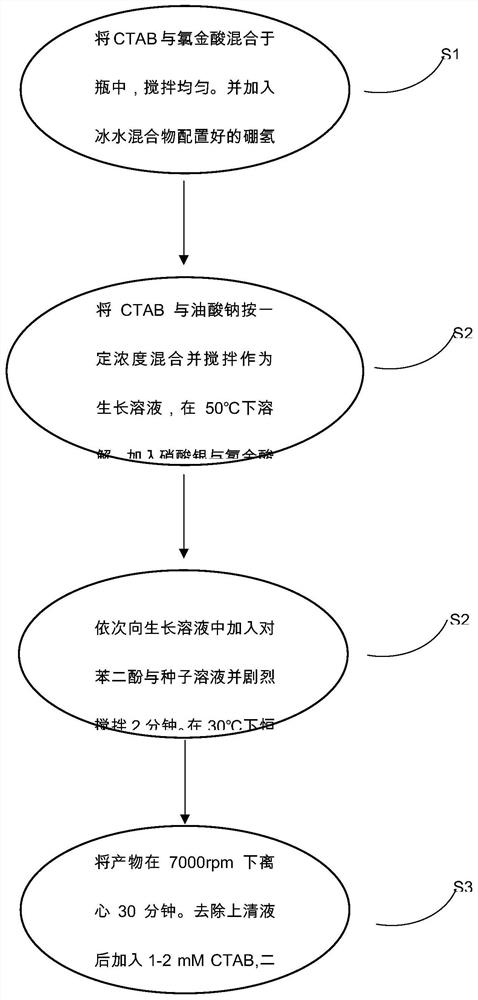

[0024] see figure 1 , as the preparation method of the gold nanomaterials grown under the low surfactant concentration that the present invention proposes, specifically comprise the following steps

[0025] Step S1, preparing a seed solution.

[0026] Step S2, preparing a growth solution and performing growth. The C-C double bond in sodium oleate will grow Au in solution 3+ Reverted to Au + , adding hydroquinone to Au + reduced to Au, Ag +

[0027] The purpose is to adjust the conversion rate and morphology of gold nanorods, and interact with CTAB to make gold nanocrystals grow into rods along both ends.

[0028] Step S3, washing and purifying the growth solution, extracting gold nanorod samples by centrifugation,

[0029] Dispersed in surfactant solution to prevent agglomeration.

[0030] Wherein, the step S1 includes the following steps:

[0031] S10: Mix 10mL 0.1M CTAB with 0.25mL 10mM HAuCl 4 Mix in the bottle, use the ice-water mixture and weighed a certain amou...

Embodiment 1

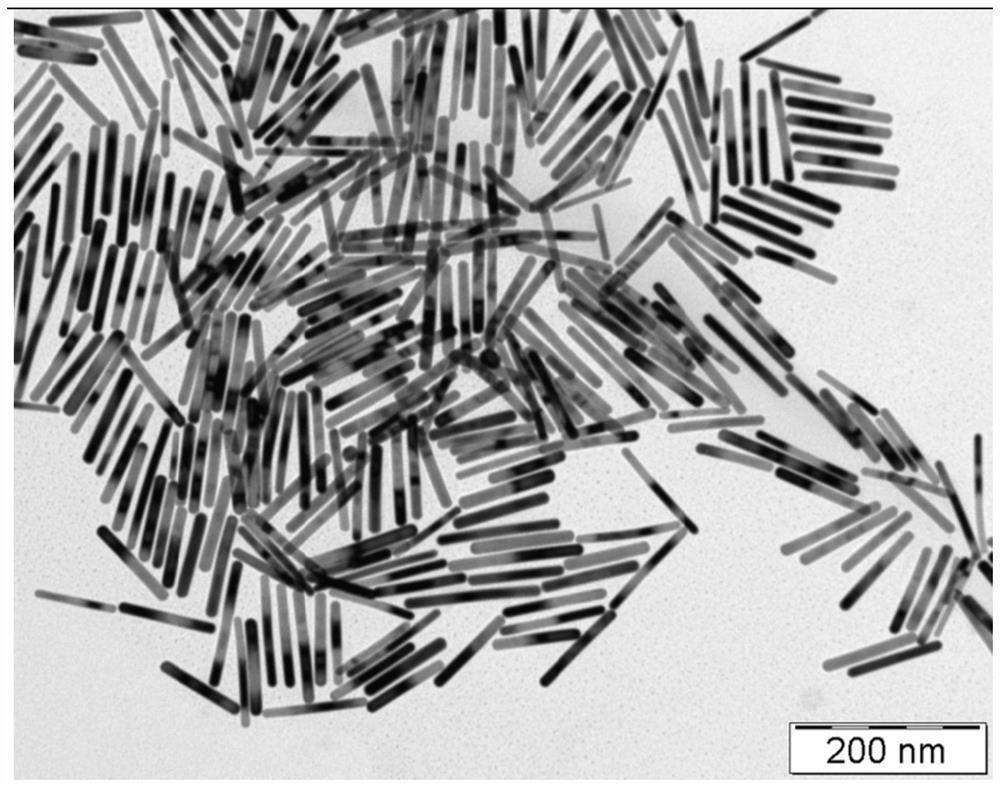

[0039] Mix 10mL CTAB (0.1M) with 0.25mL HAuCl 4 (10mM) is mixed in the bottle, and a certain mass of NaBH 4Mix to form a 0.01M solution, and add 0.6mL to the bottle and stir vigorously. The solution turns from golden yellow to brown, which is the seed solution. 18.5 mL of CTAB (0.1 M) and 0.124 g of NaOL were dissolved in 29 mL of water at 50°C. After dissolution, the solution was cooled to 30 °C, and then 1.8 mL of AgNO was added 3 (4mM) solution. and kept at 30°C for 15 minutes, then added 0.5mL HAuCl 4 (10mM). After 60-90 minutes of stirring (400 rpm), the solution changed from golden yellow to colorless. This is the growth solution. To the growth solution was added sequentially 800 μL hydroquinone solution (0.1 M), 80 μL seed solution with vigorous stirring (1200 rpm). The final solution was left to stand for 12 hours in a 30°C water bath.

Embodiment 2

[0041] Mix 10mL CTAB (0.1M) with 0.25mL HAuCl 4 (10mM) is mixed in the bottle, and a certain mass of NaBH 4 Mix to form a 0.01M solution, and add 0.6mL to the bottle and stir vigorously. The solution turns from golden yellow to brown, which is the seed solution. 18.5 mL of CTAB (0.1 M) and 0.124 g of NaOL were dissolved in 29 mL of water at 50°C. After dissolution, the solution was cooled to 30 °C, and then 1.8 mL of AgNO was added 3 (4mM) solution. and kept at 30°C for 15 minutes, then added 0.5mL HAuCl 4 (10mM). After 60-90 minutes of stirring (400 rpm), the solution changed from golden yellow to colorless. This is the growth solution. 1000 μL of hydroquinone solution (0.1 M), 80 μL of seed solution were added sequentially to the growth solution with vigorous stirring (1200 rpm). The final solution was left to stand for 12 hours in a 30°C water bath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com