Air-assisting atomized urea spraying system and control method thereof

A urea injection system and air-assisted technology, which is applied to the electrical control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., can solve the problems of high cost and low system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

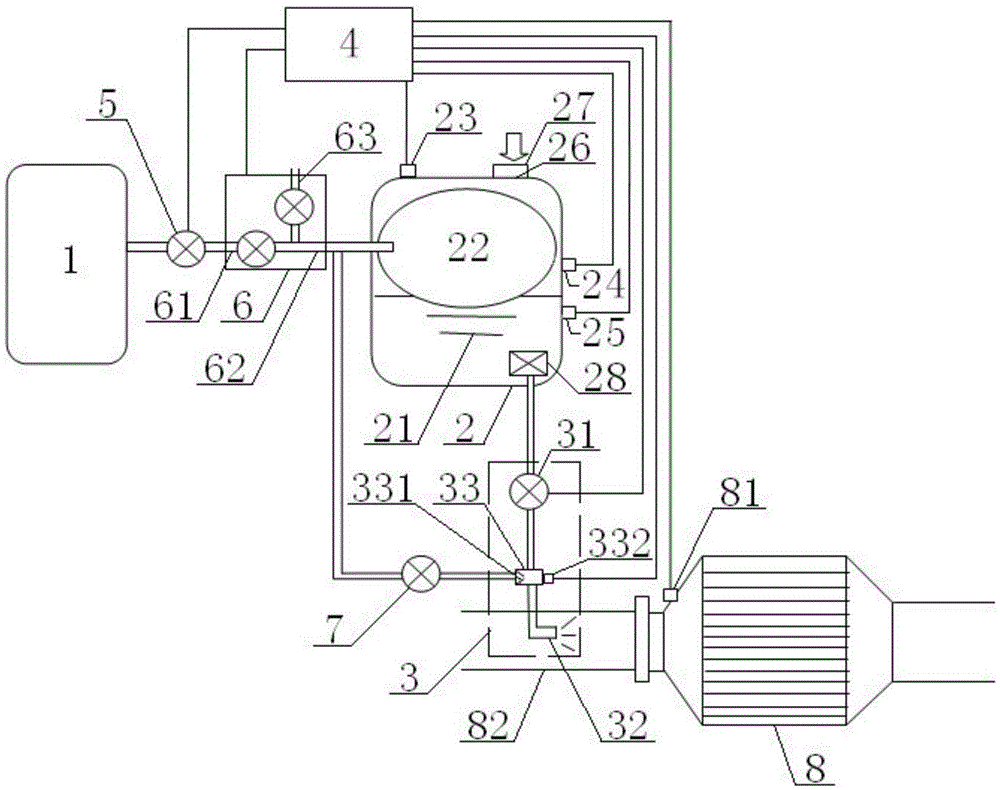

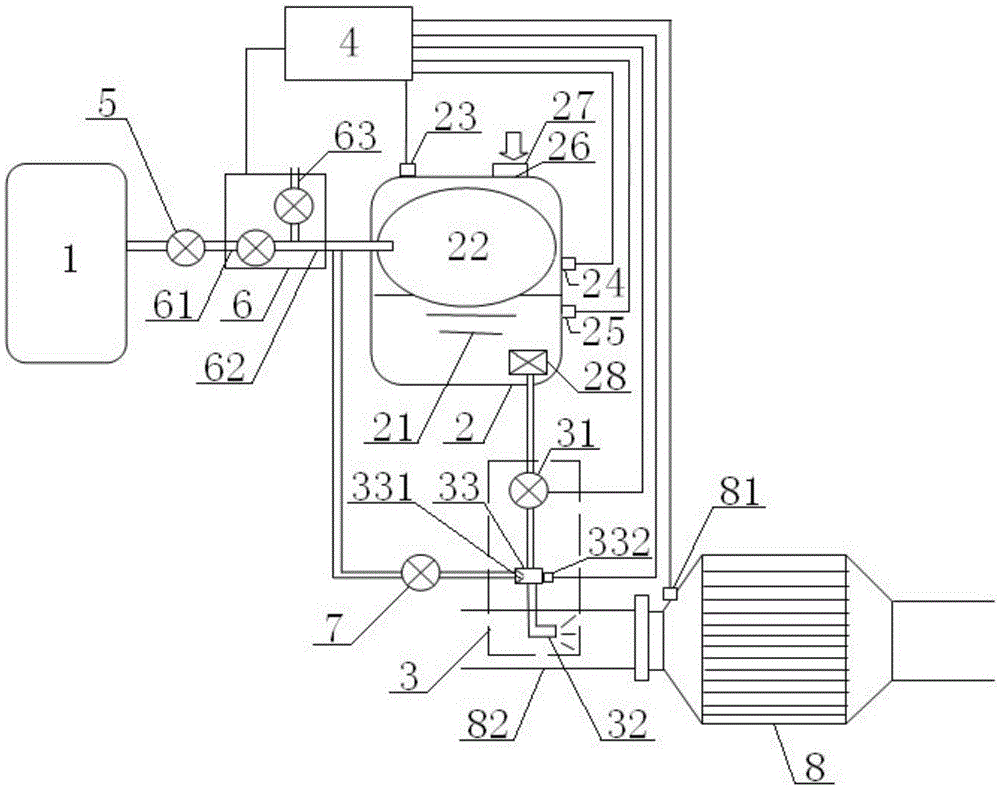

[0063] see Figure 1 to Figure 2 , an air-assisted atomized urea injection system, comprising an air source 1, an airbag pressure tank 2, and an injection pipeline system 3, the air source 1 is connected to the airbag pressure tank 2 through an air circuit, and the airbag pressure tank 2 is connected to the injection pipeline system 3 Liquid connection, the injection pipeline system 3 is connected with the control unit 4 for signals, the inside of the air bag pressure tank 2 is provided with a urea solution area 21 and an air bag 22, and the urea solution area 21 is provided with an air bag 22, and the air bag 22 is sequentially passed through two The air outlet 62 of the one-position three-way valve 6, the air inlet 61 of the two-position three-way valve 6, and the pressure-stabilizing valve 5 are connected to the air path of the air source 1, and the air bag 22 passes through the air outlet 62, The exhaust port 63 of the two-position three-way valve 6 communicates with the a...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] see Figure 1 to Figure 2 , the air bag pressure tank 2 is provided with a pressure sensor 23, a liquid level sensor 24, a temperature sensor 25, and the pressure sensor 23, the liquid level sensor 24, and the temperature sensor 25 are all connected with the control unit 4 signals; The top is provided with a liquid increasing port 26, the liquid increasing port 26 is provided with a liquid increasing port cover 27, and the bottom of the air bag pressure tank 2 is provided with a filter 28 connected to the metering valve 31 in a liquid way.

Embodiment 3

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] see Figure 1 to Figure 2 , the inside of the mixing chamber 33 is provided with an orifice 331 connected to the air path of the pneumatic switching valve 7, the mixing chamber 33 is provided with a mixing chamber pressure sensor 332, and the mixing chamber pressure sensor 332 is connected to the control unit 4 for signals; The air-assisted atomizing urea injection system also includes an SCR post-processor 8, the air inlet of the SCR post-processor 8 is connected to the gas path of the exhaust pipe 82, and the exhaust pipe 82 passes through the nozzle 32, the mixing chamber 33, and the metering valve 31 in turn. It is connected to the urea solution area 21 in a liquid way, and the SCR post-processor 8 is provided with an SCR post-processor temperature sensor 81 , and the SCR post-processor temperature sensor 81 is connected to the control unit 4 for signals.

[0071] The control air source 1 is spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com