Method for separation and enrichment of copper and arsenic in copper smelting acidic wastewater

A technology for copper smelting and arsenic separation, which is applied in the intersecting fields of metallurgical engineering and environmental engineering, can solve problems such as waste of resources, and achieve the effects of improving copper grade, economic efficiency, and activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

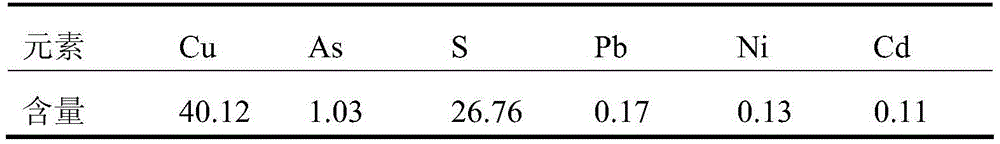

[0022] Take 500ml of polluted acid from a copper smelting enterprise, the main components are copper 2.6g / L, arsenic 7.8g / L, and sulfuric acid mass concentration 230g / L. Sodium sulfide was first added at a ratio of S / As molar ratio of 1.2, reacted at 30° C. for 1 hour, and then filtered to obtain sulfide slag. The obtained vulcanized slag is ball milled for 1 hour under the conditions of using water as the ball milling medium, the ball-to-material ratio is 1:5, and the ball milling speed is 500r / min, and the activated vulcanized slag is added into the Into 500ml of polluted acid wastewater, ultrasonic dispersion for 0.5h, ultrasonic frequency of 20kHz, reaction at 50°C for 2h, after filtration, copper-rich slag and arsenic-rich solution were obtained, the copper concentration in the solution was reduced to 9.7mg / L, and the copper recovery rate was 99.6 %. The main elements and content of copper-rich slag are shown in Table 1:

[0023] The main element and content (%) of tabl...

Embodiment 2

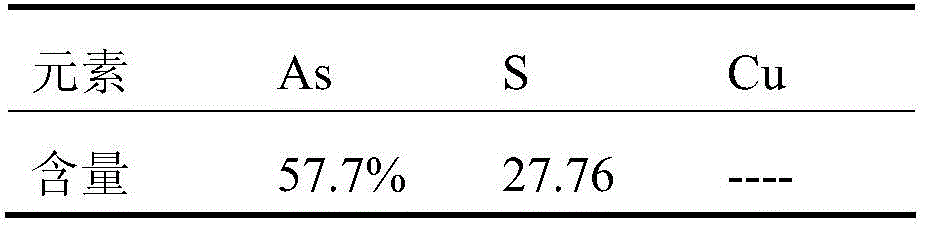

[0030] Take 500ml of polluted acid from a copper smelting enterprise, the main components are copper 3.6g / L, arsenic 8.9g / L, sulfuric acid mass concentration 180g / L. According to the ratio of S / As molar ratio of 1.1, hydrogen sulfide gas is first introduced, reacted at 40° C. for 1 hour, and then filtered to obtain sulfide slag. The obtained vulcanized slag is ball milled for 1 hour under the conditions of using water as the ball milling medium, the ball-to-material ratio is 1:8, and the ball milling speed is 600r / min. Into 500ml of polluted acid wastewater, ultrasonic dispersion for 1h, ultrasonic frequency is 40kHz, reaction at 40°C for 1.5h, after filtration, copper-rich slag and arsenic-rich solution are obtained, the copper content in the solution is 5.3mg / L, and the copper recovery rate is 99.7% . The copper grade in the copper-rich slag reaches 42.1%, and the arsenic content is 0.89%, while the arsenic sulfide slag is directly added to the polluted acid without mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com