A fixed-bed pure oxygen continuous gasification device and process suitable for various coal qualities

A gasification device and fixed bed technology, applied in the field of coal gasification, can solve the problems of high residual carbon content in ash, low effective conversion rate, and high raw material requirements, and achieve the effects of protecting the environment, reducing raw material consumption, and high steam decomposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

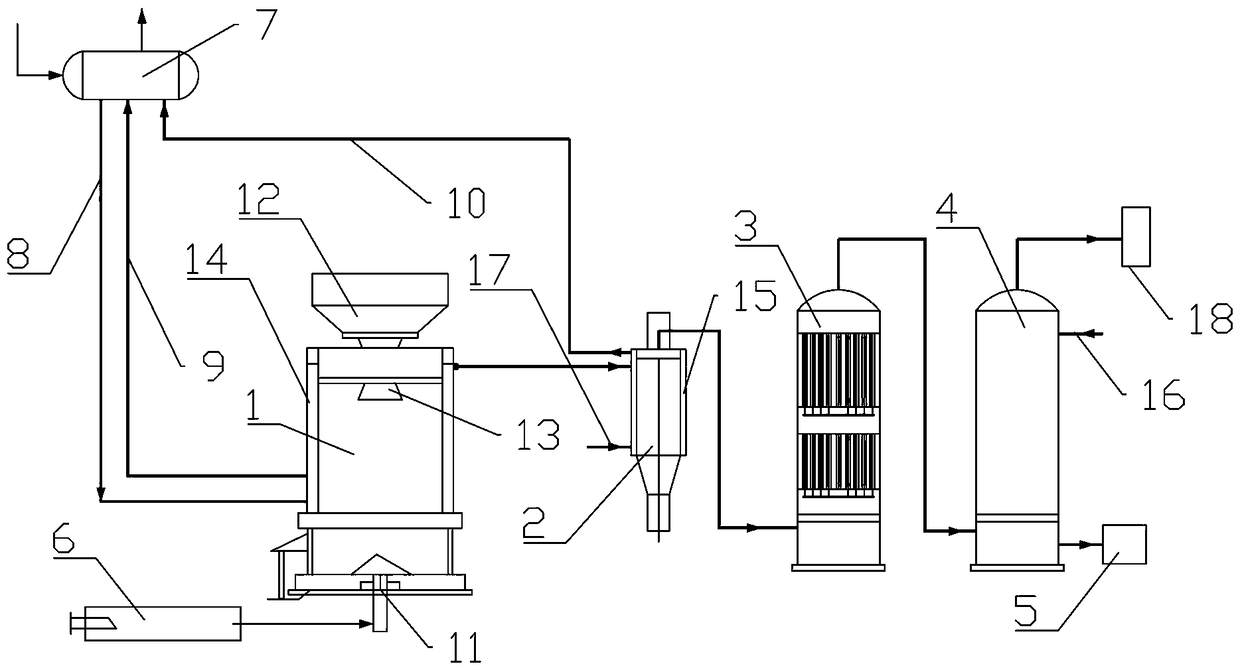

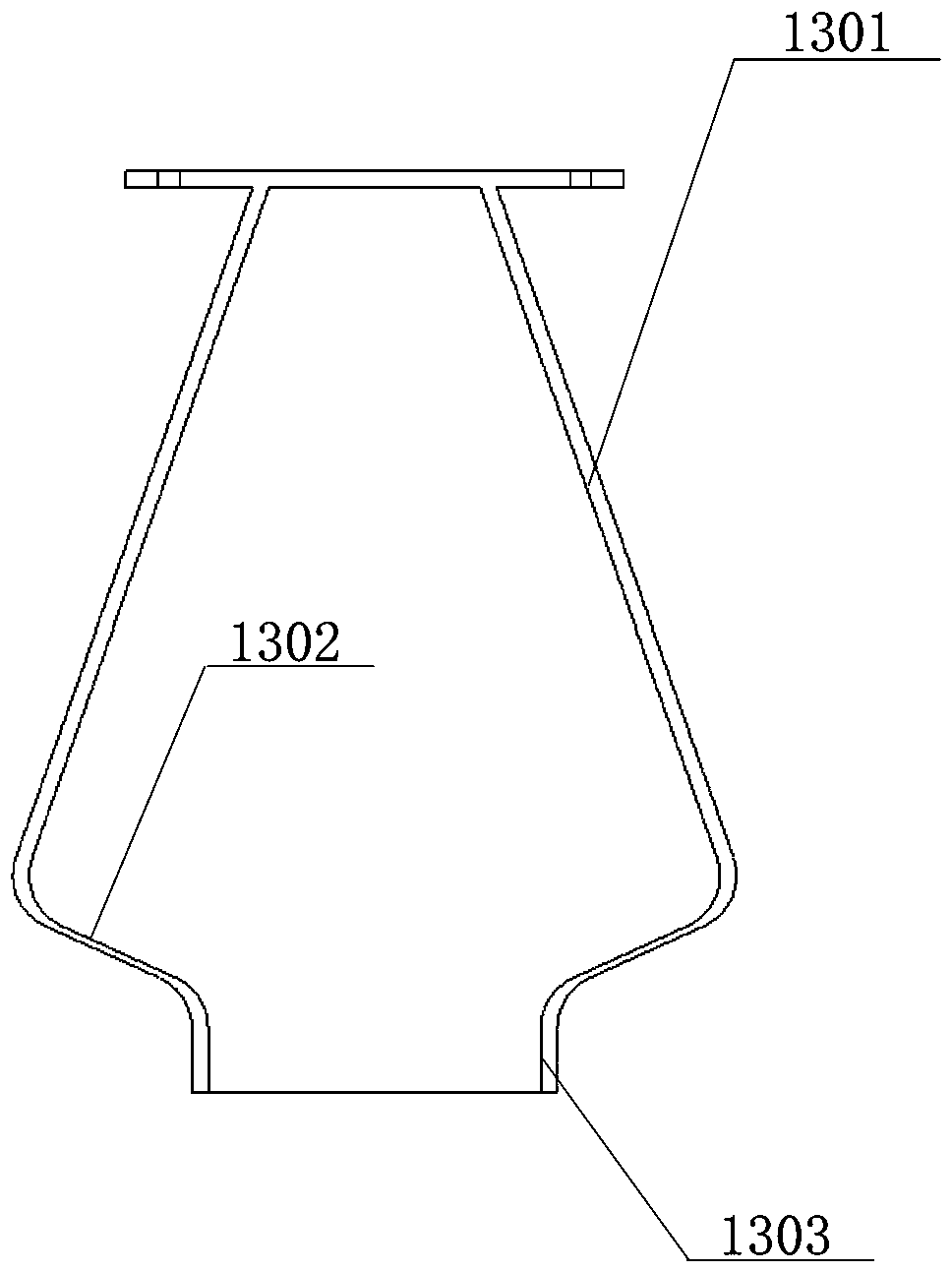

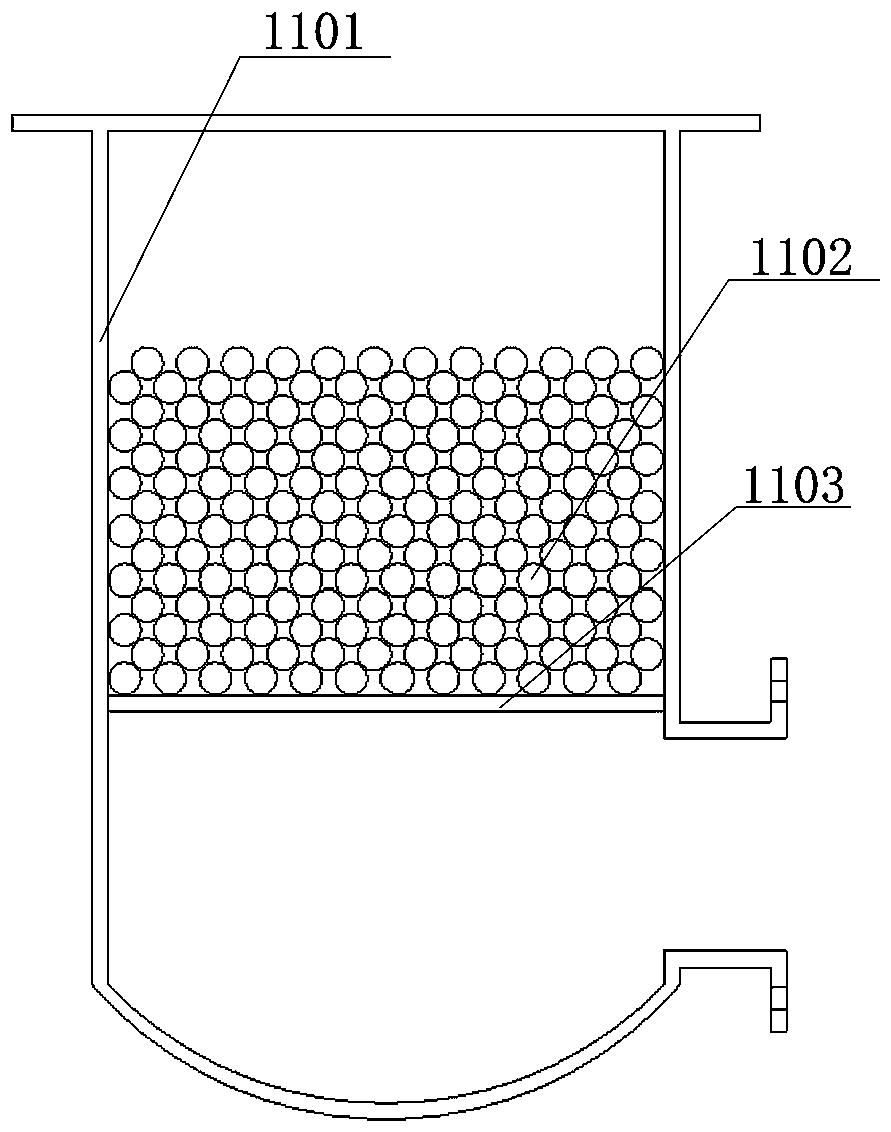

[0020] Such as figure 1 As shown in -3, a fixed-bed pure oxygen continuous gasification device suitable for various coal qualities, including gas mixer 6, fixed-bed coal gasifier 1, cyclone dust collector 2, heat pipe heat exchanger 3 and gas Washing tower 4; the top of the gas washing tower 4 is connected to a gas tank 18, a feed bin 12 is arranged above the fixed-bed coal gasifier 1, and an anti-deviation device 13 is arranged in the fixed-bed coal gasifier 1, and the bottom of the feed bin 12 and the anti-deviation device The top of the deflection device 13 is connected through a flange; the fixed bed coal gasifier 1 is provided with a water wall 14 outside, and the cyclone dust collector 2 is provided with a water cooler 15 outside.

[0021] The fixed-bed pure oxygen continuous gasification device a...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is that the pressure in the fixed bed coal gasifier is 20kPa, and the raw coal is anthracite lump coal.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is that the pressure in the fixed bed coal gasifier is 80kPa, and the raw coal is briquette.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com