Preparation method of wear-resistant adhesive tape

A technology of adhesive tape and mass parts, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of acid and alkali corrosion resistance, high cost, poor ductility, etc., to improve wear resistance and tensile performance , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

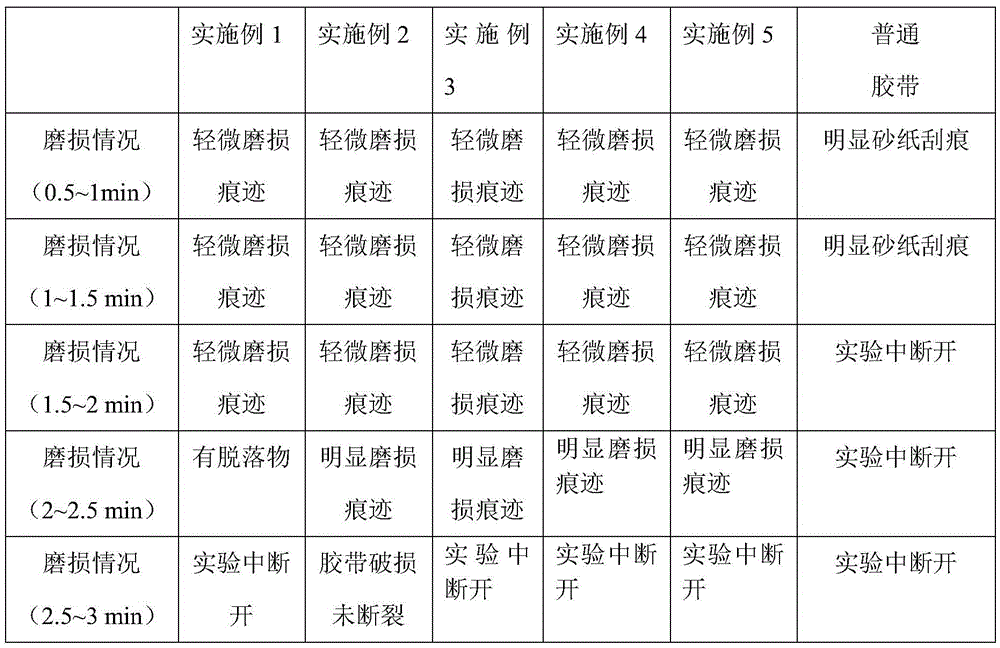

Examples

Embodiment 1

[0027] A preparation method of wear-resistant adhesive tape, is characterized in that, comprises the following steps:

[0028] (1) 40 mass parts styrene-butadiene rubber, 30 mass parts natural rubber, 15 mass parts high styrene resin, 1 mass part cobalt naphthenate, 2 mass parts UV-9, 20 mass parts diisononyl phthalate Ester, 2 parts by mass of N-phenyl-α-aniline, 15 parts by mass of polyester staple fiber, 5 parts by mass of length 10 μm, calcium carbonate whiskers with an aspect ratio of 15, mix uniformly to obtain a mixture;

[0029] (2) Plasticize the mixture for 6 minutes through a double-roll mill, and the plasticizing temperature is 75°C; then enter the extruder and plasticize for 6 times to obtain the first material;

[0030] (3) The first material passes through a five-roll calender, and is repeatedly rolled into a film substrate in the same direction, and the temperatures of rolls 1 to 5 are respectively 70°C, 72°C, 72°C, 74°C, and 76°C;

[0031] (4) Coating the adh...

Embodiment 2

[0034] A preparation method of wear-resistant adhesive tape, is characterized in that, comprises the following steps:

[0035] (1) With 50 mass parts styrene-butadiene rubber, 20 mass parts natural rubber, 15 mass parts phenolic resin, the mixture of 2 mass parts cobalt naphthenate and zinc diethyldithiocarbamate, 4 mass parts zinc oxide, 30 Parts by mass of dioctyl phthalate, 3 parts by mass of N-phenyl-α-aniline, 20 parts by mass of polyester staple fiber, 6 parts by mass of calcium carbonate whiskers with a length of 15 μm and an aspect ratio of 20, mixed uniformly get the mixture;

[0036] (2) Plasticize the mixture for 7 minutes through a double-roll mill, and the plasticizing temperature is 80° C.; then enter the extruder and plasticize 8 times to obtain the first material;

[0037] (3) The first material passes through a five-roll calender, and is repeatedly rolled into a film substrate in the same direction, and the temperatures of rolls 1 to 5 are respectively 70°C, ...

Embodiment 3

[0041] A preparation method of wear-resistant adhesive tape, is characterized in that, comprises the following steps:

[0042] (1) with 48 mass parts styrene-butadiene rubber, 26 mass parts natural rubber, 18 mass parts high styrene resins, 2 mass parts cobalt isooctanoate, 3 mass parts titanium oxide, 25 mass parts diisononyl phthalate, 3 parts by mass of N-phenyl-α-aniline, 18 parts by mass of polyester staple fiber, 6 parts by mass of length 18 μm, calcium carbonate whiskers with an aspect ratio of 17, and mix uniformly to obtain a mixture;

[0043] (2) Plasticize the mixture for 6 minutes through a double-roll mill, and the plasticizing temperature is 80° C.; then enter the extruder and plasticize 6 times to obtain the first material;

[0044] (3) The first material passes through a five-roll calender, and is repeatedly rolled into a film substrate in the same direction, and the temperatures of rolls 1 to 5 are respectively 72°C, 73°C, 73°C, 74°C, and 76°C;

[0045] (4) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com