Organic glass seamless polymerization device and method

A plexiglass and polymerization device technology, which is applied in the field of glass polymerization, can solve the problems of high labor cost, difficult to guarantee quality, low body and other problems, and achieve the effects of high automation, cost saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

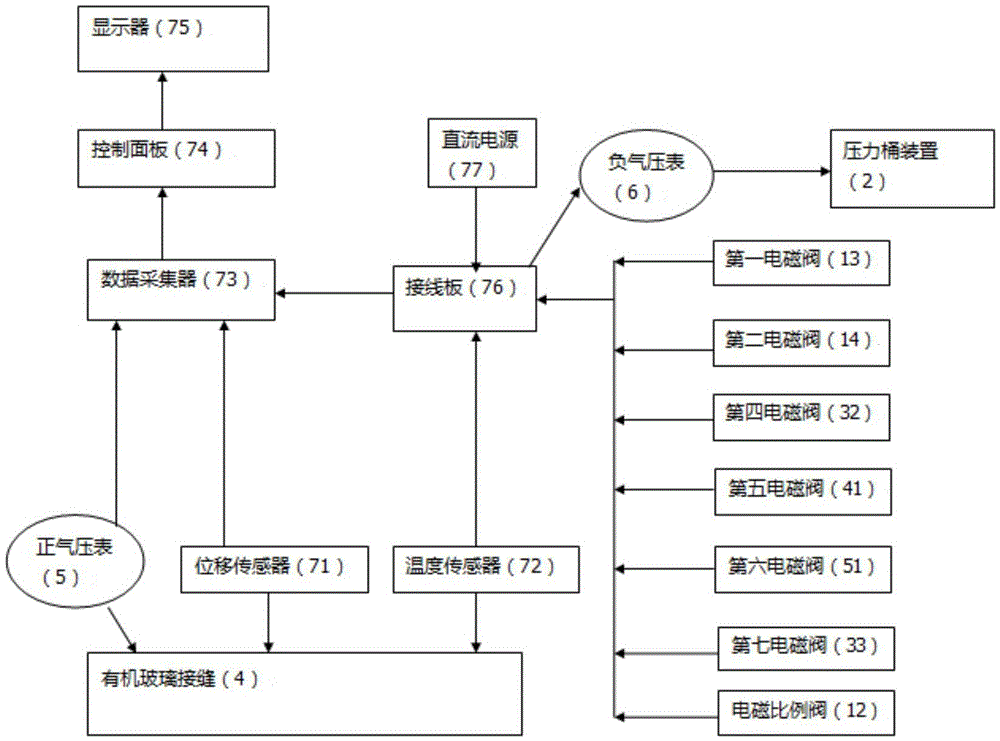

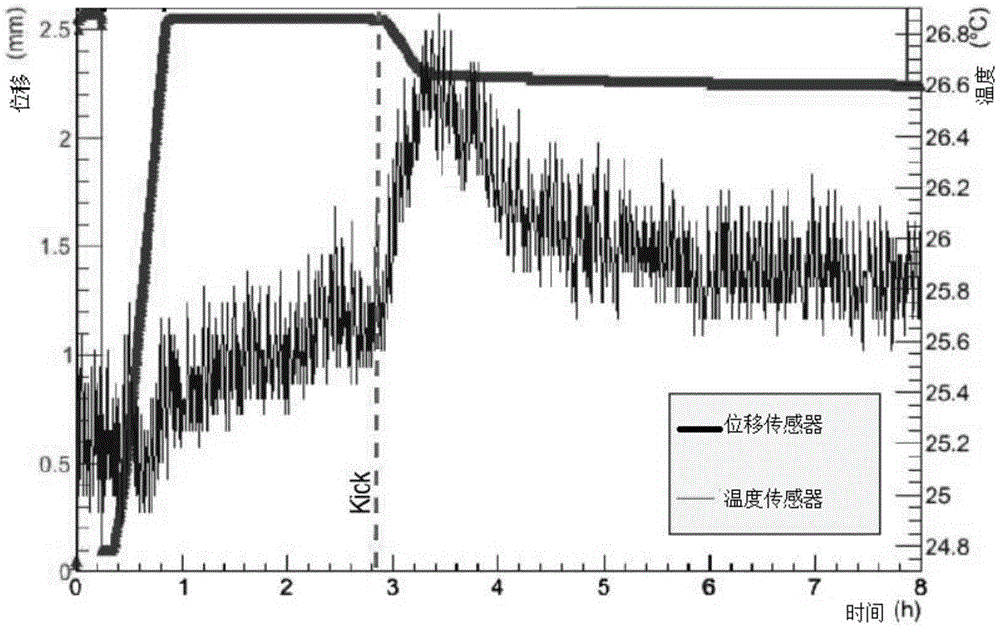

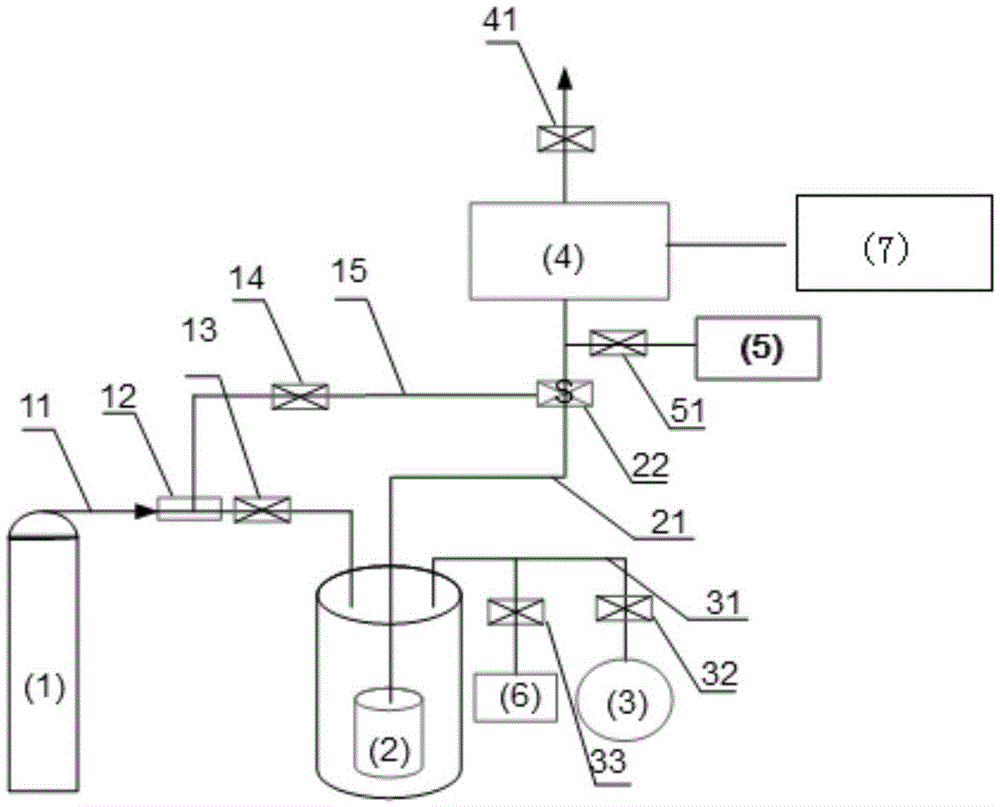

[0051] like Figure 1 ~ Figure 4 As shown, the plexiglass seamless polymerization device of the present invention includes a tooling construction system, a glue injection system, and a control system. film at the slit, and the fixture fixes the film on the surface of the plexiglass.

[0052] Described frock fixture comprises fixed frame 42, the adjustment plate 43 that is arranged on the fixed frame; Between described adjustment plate 43 and fixed frame 42, connect by screw 45, on described screw 45, be positioned at described fixed frame 42 and adjustment plate 43 A first nut 48 and a second nut 47 are arranged between them, the first nut is close to the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com