Method for catalyzed synthesis of lubricating base oil from supported ionic liquid

A technology for synthesizing lubricating oil and ionic liquids, which is applied in chemical instruments and methods, preparation of organic compounds, catalytic reactions, etc., can solve unseen problems, achieve short reaction time, mild reaction conditions, and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

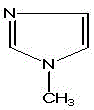

[0034] Embodiment 1 (synthesis of ionic liquid) the preparation method of imidazole acetate ionic liquid

[0035] Weigh 8.21g of N-methylimidazole and 6.01g of acetic acid with a molar ratio of 1:1 into a 250ml three-necked flask, add 2ml of water as a solvent, rotate and stir, and control the temperature at 80°C. Under these conditions, the reaction was carried out for 6h, and a pale yellow liquid was obtained.

[0036] The obtained light yellow liquid was subjected to vacuum distillation, the vacuum degree of vacuum distillation was controlled to be 0.07MPa, the top temperature was 92°C, and the distillation time was 3h, to obtain the imidazole acetate ionic liquid [Hmim]CH 3 COO.

Embodiment 2

[0037] Embodiment 2 (synthesis of ionic liquid) preparation method of imidazolium n-butyrate ionic liquid

[0038] Weigh 8.21g of N-methylimidazole and 8.82g of n-butyric acid with a molar ratio of 1:1 in a 250ml three-necked flask, add 2ml of water as a solvent, stir with a magnetic stirrer, heat with an electric heating mantle, and reflux the condensed water. The reaction temperature was controlled at 80° C., and the reaction was carried out for 7 hours to obtain a yellow liquid.

[0039] The obtained liquid was subjected to vacuum distillation, the vacuum degree was controlled to be 0.05MPa, the top temperature was about 75°C, and the distillation time was 4h. That is, the imidazolium n-butyrate ionic liquid [Hmim]C 4 h 7 o 2 .

Embodiment 3

[0040] Embodiment 3 (synthesis of ionic liquid) the preparation method of imidazolium phosphate ionic liquid

[0041] Weigh 16.4g of N-methylimidazole and 19.6g of phosphoric acid with a molar ratio of 1:1 in a 250ml three-necked flask, add 3ml of water as a solvent, stir with a magnetic stirrer, heat with an electric heating mantle, and reflux the condensed water. For the reaction, the reaction temperature was controlled at 80° C., and the reaction was carried out for 7 hours to obtain a yellow liquid.

[0042] Distill the obtained liquid under reduced pressure, control the vacuum degree to 0.05MPa, the top temperature is about 75°C, and the distillation time is 3h, to obtain the imidazole phosphate ionic liquid [Hmim]H 2 PO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com