A hydroacoustic cavitation loop reactor

A loop reactor and acoustic cavitation technology, applied in chemical instruments and methods, water pollutants, reflux water treatment, etc., can solve the problems of ultrasonic cavitation application limitations, difficulty in industrialization, and low cavitation intensity, and achieve enhanced The effects of sewage treatment capacity, easy management, and simple technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

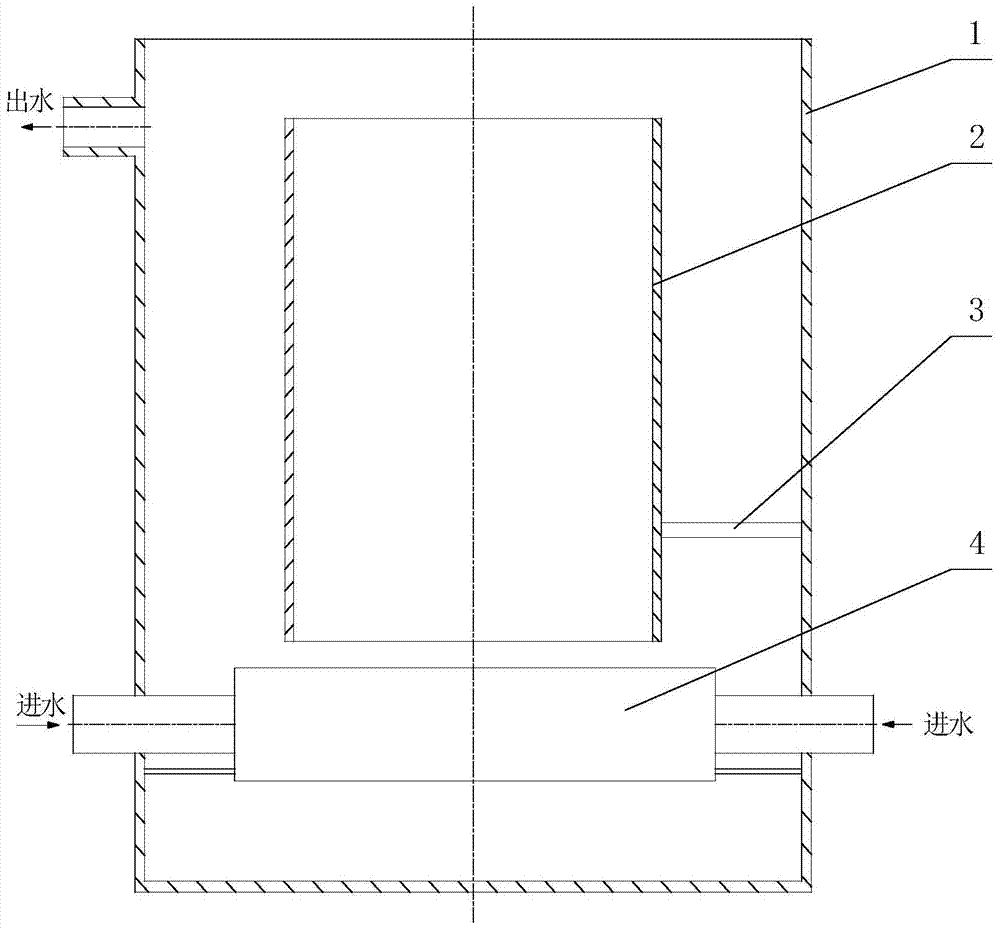

[0022] Depend on figure 1 It can be seen that the hydroacoustic cavitation loop reactor of this embodiment is composed of an outer cylinder 1 , a guide cylinder 2 , a fixed rod 3 and a cavitation nozzle 4 .

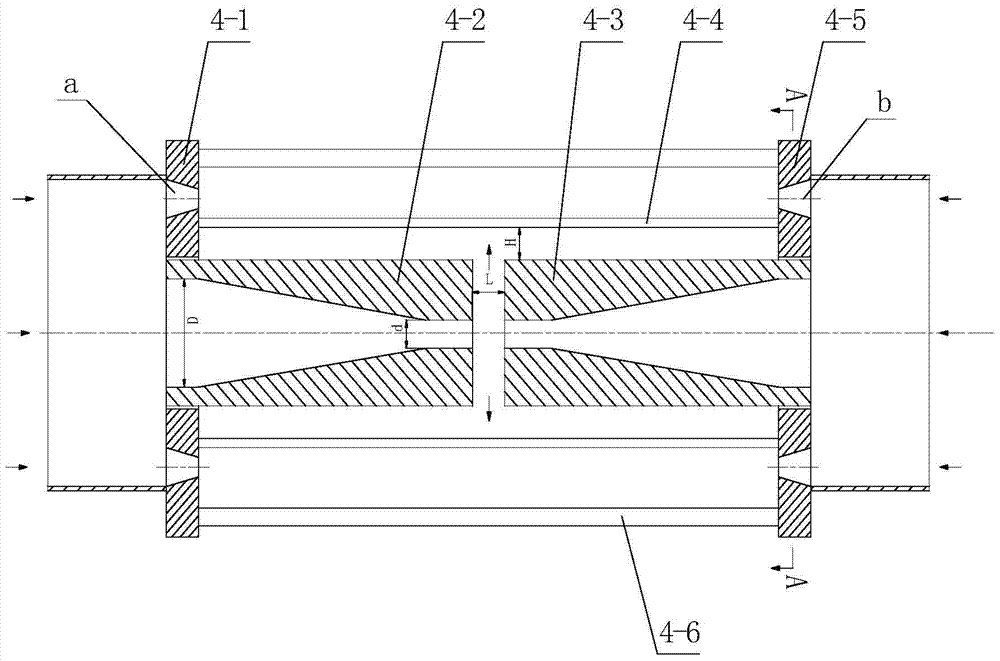

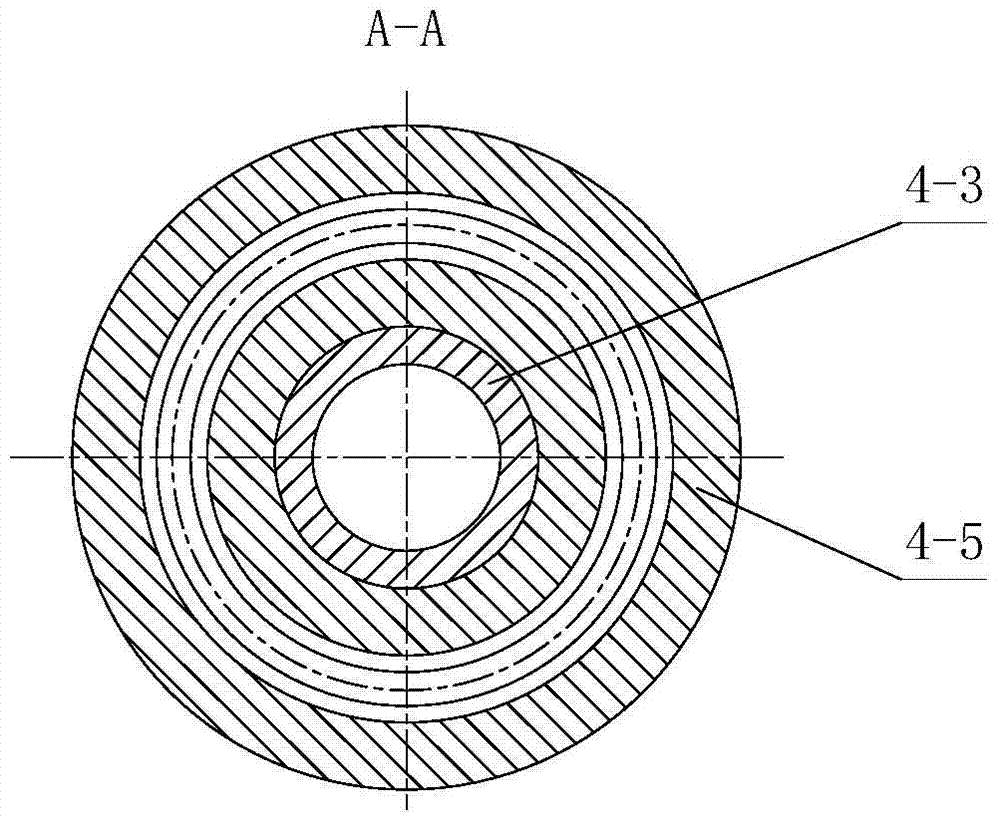

[0023] The outer cylinder 1 of the present embodiment is a cylindrical structure with a diameter of 60 cm. A water outlet is opened on the upper side wall of the outer cylinder 1. The inner cavity of the outer cylinder 1 is 45 cm from the bottom of the outer cylinder 1 through the fixed rod 3 and the outer cylinder 1. The threaded fastener is fixedly installed with a guide tube 2 with a diameter of 50 cm. The central axis of the guide tube 2 coincides with the central axis of the outer tube 1. The rod 3 is fixedly equipped with a cavitation nozzle 4, see figure 2 and 3 , the cavitation spray head 4 of the present embodiment is composed of the first fixed plate 4-1, the first nozzle 4-2, the second nozzle 4-3, the vibrating rod 4-4, the second fixed plate 4-5 and the co...

Embodiment 2

[0027] see Figure 4In this embodiment, a guide tube 2 with a diameter of 46 cm is fixedly installed at a position where the inner cavity of the outer tube 1 is 45 cm from the bottom of the outer tube 1 through a fixed rod 3 and a threaded fastener, and the lower port of the guide tube 2 is outside the The height of the bottom of the tube 1 is 20 cm, and a circular installation hole is processed on the opposite side walls of the bottom of the guide tube 2, and two oppositely arranged joints 5 are respectively threaded on the circular installation holes. Joint 5 is a coaxial annular double-channel structure composed of a central channel and an annular channel. It is a commercially available standard joint. The two joints 5 are connected through the cavitation nozzle 4. The other ends of the joint 5 are connected to 1 The external water inlet pipe is connected.

[0028] The cavitation nozzle 4 of the present embodiment is composed of a first fixed plate 4-1, a first nozzle 4-2,...

Embodiment 3

[0032] In this embodiment, a guide tube 2 with a diameter of 48 cm is fixedly installed in the inner cavity of the outer cylinder 1 through a fixed rod 3 and a threaded fastener. The central axis of the guide tube 2 coincides with the central axis of the outer cylinder 1. A cavitation nozzle 4 is fixedly installed directly below the guide cylinder 2 through a fixed rod 3 welded on the inner wall of the outer cylinder 1 .

[0033] The cavitation nozzle 4 of the present embodiment is composed of a first fixed plate 4-1, a first nozzle 4-2, a second nozzle 4-3, a vibrating rod 4-4, a second fixed plate 4-5 and a connecting rod 4- 6 components, the first fixed plate 4-1 and the second fixed plate 4-5 are arranged oppositely and connected into an integral structure through three connecting rods 4-6, the first fixed plate 4-1 and the second fixed plate 4-5 The outer wall is fixed to the inner wall of the outer cylinder 1 through the fixing rod 3, and a nozzle installation hole is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com