Warp knitting and printing all-in-one machine

An all-in-one machine and warp knitting machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of difficult thermal transfer printing process, inability to complete accurate transfer printing, and time-consuming connection, so as to improve the efficiency of fabric printing , Simplified fabric printing process, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

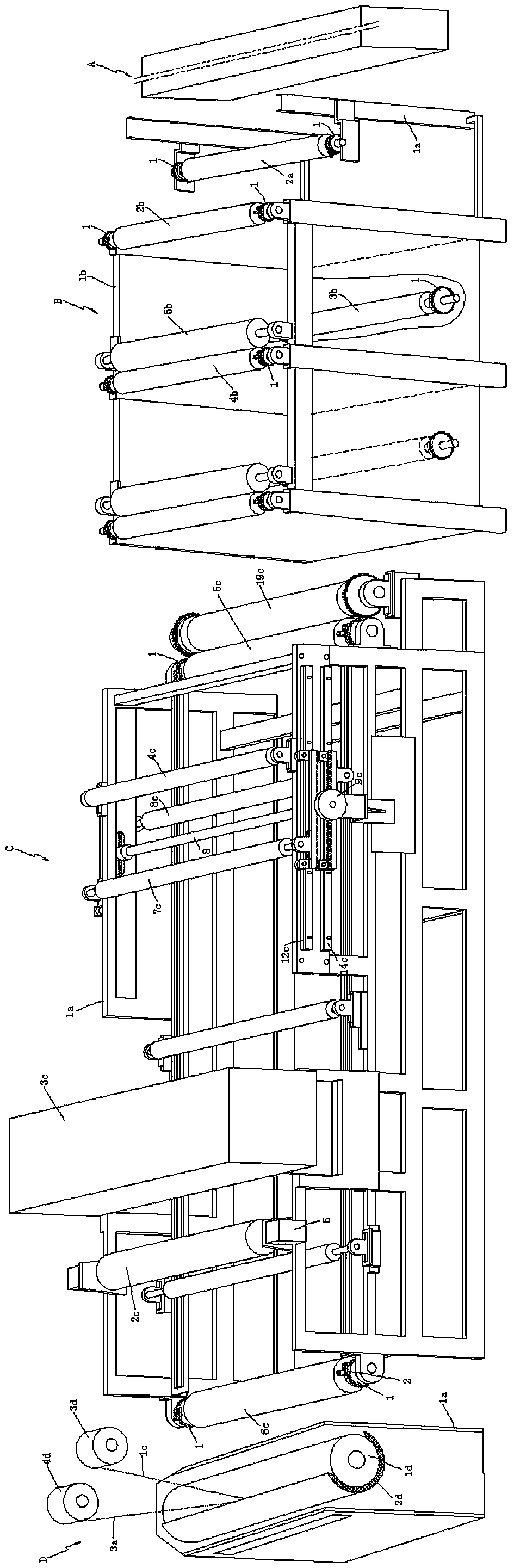

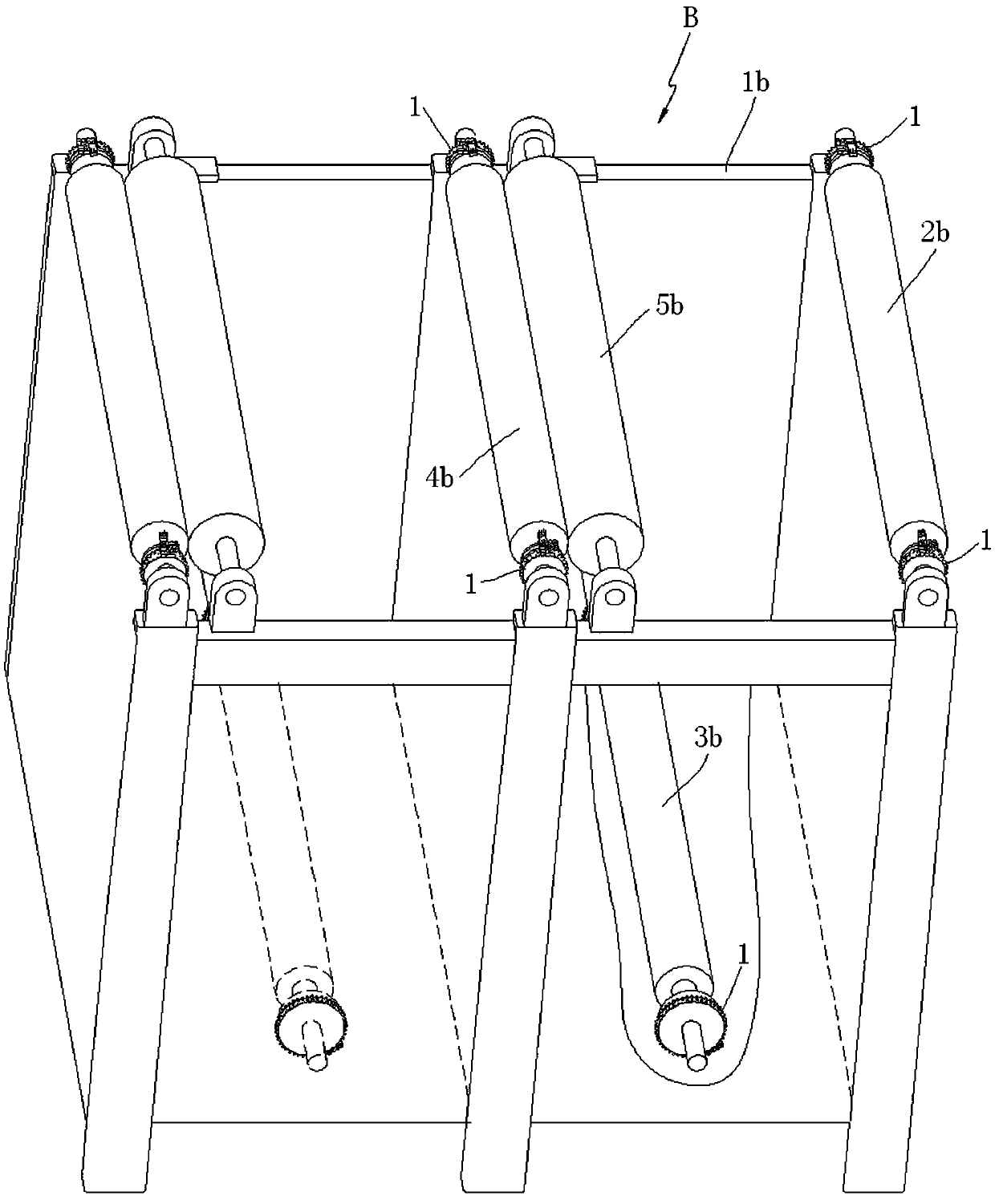

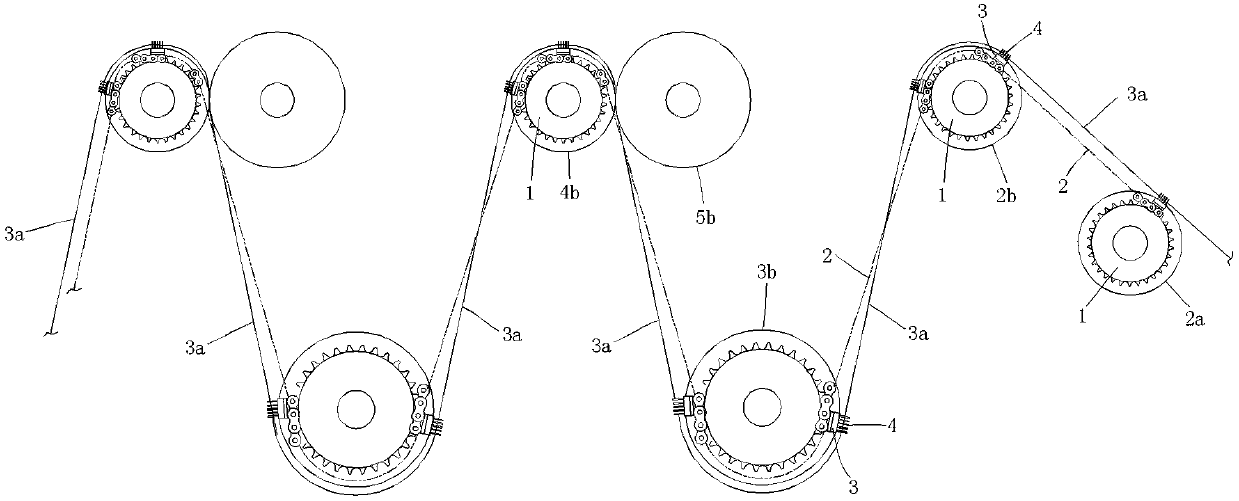

[0026] see Figure 1 to Figure 9 The warp knitting and printing integrated machine shown includes a warp knitting machine A and a frame 1a, and the warp knitting machine A includes a knitting mechanism that can knit the yarn in loops and pulls the fabric 3a that is finished by the knitting mechanism. The output first pulling roller 2a, the first pulling roller 2a is rotatably installed on the frame 1a through a bearing, and the warp knitting and printing machine also includes a A water washing mechanism B that washes the fabric 3a that is pulled out by the first pulling roller 2a, and combines the washed fabric with thermal transfer paper and with the pattern printed on the thermal transfer paper The print-to-flower mechanism C that matches the patterns, and the heat-transfer mechanism D that thermally transfers the combined fabric and heat-transfer paper to complete fabric printing.

[0027] In the present invention, as figure 1 , 2 , 3, the water washing mechanism B inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com