A cloth-free rubber air-guiding long bellows and its forming device and forming method

A molding device and bellows technology, applied in the field of rubber products, can solve the problems of inability to conduct gas normally, inability to bend and use at will, and increase the risk of use, so as to avoid the risk of use, improve the vulcanization effect, and achieve excellent air tightness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

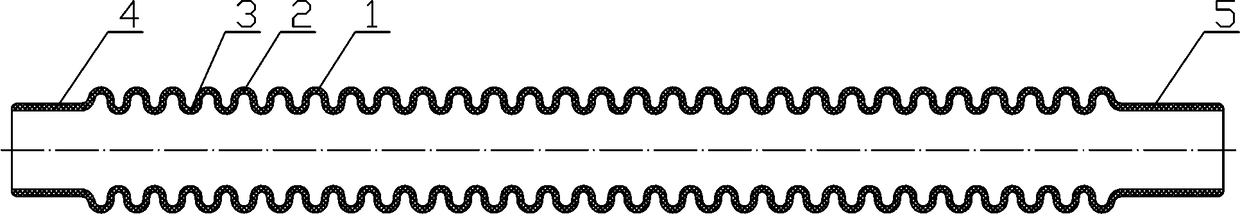

[0041] Such as figure 1 As shown, a long corrugated pipe without cloth rubber air guide includes a corrugated pipe body 1, and the corrugated pipe body 1 includes a pipe body wave crest 2 and a pipe body wave valley 3, and the pipe body wave peak 2 and pipe body wave valley 3 together form a corrugated pipe For the corrugated section of the pipe, the left end of the corrugated pipe body 1 is a left straight section 4, and the right end is a right straight section 5. The above-mentioned corrugated structure can ensure that the bellows has good flexibility, and at the same time can be easily bent, thereby ensuring that the bellows can ventilate normally even when bent by 180°, thereby ensuring its safety.

[0042] Further, the bellows body 1 is made of cloth-free rubber material. By using non-cloth rubber material for molding, it can effectively avoid the problem that although the rubber bellows with cloth has high strength, this method adds one or more processes, which is more...

Embodiment 2

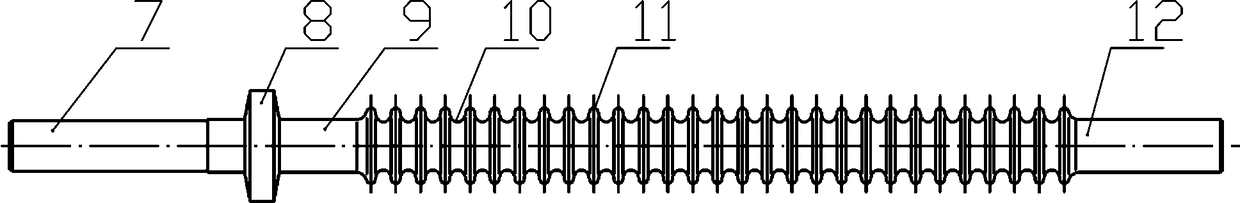

[0053] Such as Figure 1-5 As shown, a forming device for forming a cloth-free rubber air-conducting long bellows, which includes: a flat vulcanizer, a corrugated mandrel, a film pressing device and a demoulding device.

[0054] Further, the corrugated core mold includes a core mold extension section 7, and the right side of the core mold outer body section 7 is provided with a positioning collar 8, and the right side of the positioning collar 8 is the No. 1 optical axis section 9, and the No. 1 optical axis The right side of section 9 is the corrugated section; the corrugated section is composed of core mode peaks 11 and core mode troughs 10 ; the right side of the corrugated section is the second optical axis section 12 .

[0055] Further, wherein, the material of the corrugated mandrel rod is general-purpose mold steel, and the mold material of the air-conducting long tube of the supporting demoulding device is general-purpose mold steel, and the length of the mold and the ...

Embodiment 3

[0063] see Figure 6 A method for forming a cloth-free rubber air-conducting long corrugated pipe with a forming device for forming a non-cloth rubber air-conducting long bellows comprises the following steps:

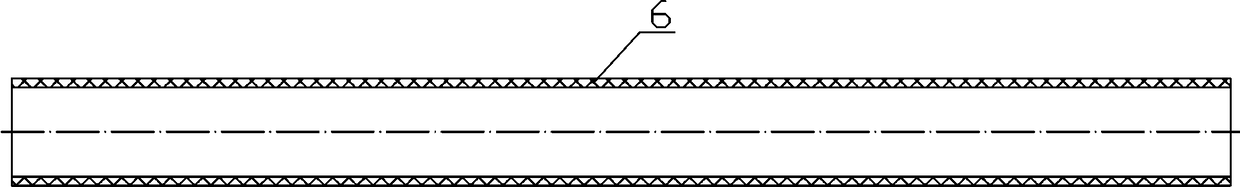

[0064] 1) Extrude the refined mixed rubber from the special mouth of the screw extruder into a straight pipe 6, the wall thickness of the straight pipe 6 extruded by the special mouth should be the same as the wall thickness of the air guide long bellows body 1, And cut into sections according to the length requirements of the air guide tube.

[0065] 2) Put the straight pipe 6 on the corrugated mandrel, and then put the corrugated mandrel with the straight pipe 6 into the laminating device with the long air guide tube, and then perform vulcanization molding on the vulcanizing machine. During the vulcanization process The vulcanization treatment is carried out by a vacuum-pumped flat vulcanizer, the vulcanization temperature is 165°C, and the vulcanization time is 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com