A method for preparing hollow ptpd nanomaterials using cuprous oxide as a template

A technology of cuprous oxide and nanomaterials, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of severe redox reaction, inability to accurately copy template morphology, rough surface of final product, etc., and achieve the effect of precise composition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

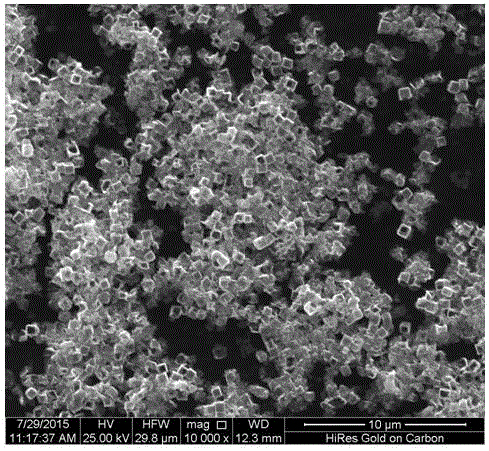

[0029] The method for preparing hollow PtPd nanomaterials with cuprous oxide as a template of embodiment 1 may further comprise the steps:

[0030] (1) Ultrasonically disperse 10 mg of cuprous oxide with a cubic structure in 10 ml of water, and add 20 mM H 2 PtCl 6 aqueous solution and 33mM Na 2 PdCl 4 aqueous solution, so that the atomic ratio Pt / Pd in the reaction solution is 4:1, PtCl 6 2 - and PdCl 4 2 -The mol ratio of the sum and cuprous oxide is 1.4: 1, stirring and reacting 60min at this temperature;

[0031] (2) Move the reaction system in step (1) into a heating device and heat it to 60°C at a heating rate of 1°C / min, and continue to react at this temperature for 120min;

[0032] (3) After the reaction is completed, the product is centrifuged at 5000 rpm for 5 min, and 20% ammonia water is added to complex and remove the cuprous oxide nucleus, and then 0.1mol / L nitric acid is added to react at 25° C. to remove the copper produced by the disproportionation re...

Embodiment 2

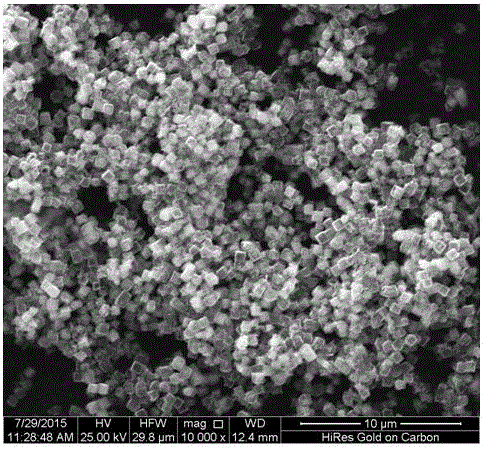

[0034] The method for preparing hollow PtPd nanomaterials with cuprous oxide as a template of embodiment 2 comprises the following steps:

[0035] (1) Ultrasonically disperse 10 mg of cuprous oxide with a cubic structure in 10 ml of water, and add 20 mM H 2 PtCl 6 aqueous solution and 33mM Na 2 PdCl 4 aqueous solution, so that the atomic ratio Pt / Pd in the reaction solution is 4:1, PtCl 6 2 - and PdCl 4 2 -The mol ratio of sum and cuprous oxide is 2.0: 1, stirring reaction 50min at this temperature;

[0036] (2) Move the reaction system of step (1) into a heating device and heat it to 62°C at a heating rate of 2°C / min, and continue to react at this temperature for 100min;

[0037] (3) After the reaction is completed, the product is centrifuged at 8000 rpm for 4 min, and 25% ammonia water is added for complexation to remove the cuprous oxide nucleus, and then 0.2 mol / L of nitric acid is added to react at 20° C. to remove the copper produced by the disproportionation re...

Embodiment 3

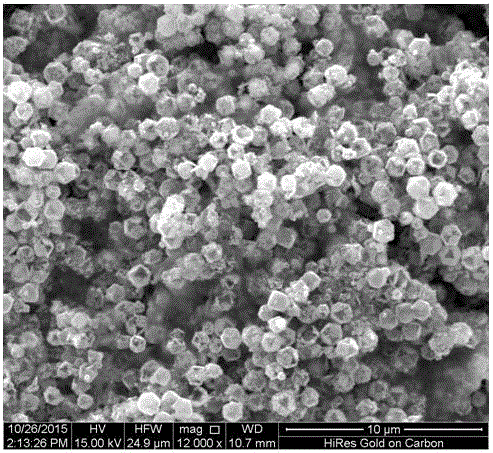

[0039]The method for preparing hollow PtPd nanomaterials with cuprous oxide as a template of embodiment 3 may further comprise the steps:

[0040] (1) Ultrasonically disperse 10 mg of cuprous oxide with a cubic structure in 10 ml of water, and add 20 mM H 2 PtCl 6 aqueous solution and 33mM Na 2 PdCl 4 aqueous solution, so that the atomic ratio Pt / Pd in the reaction solution is 4:1, PtCl 6 2 - and PdCl 4 2 -The mol ratio of the sum and cuprous oxide is 2.3: 1, stirring reaction 30min at this temperature;

[0041] (2) Move the reaction system in step (1) into a heating device and heat it to 65°C at a heating rate of 3°C / min, and continue to react at this temperature for 90min;

[0042] (3) After the reaction is completed, the product is centrifuged at 10,000 rpm for 3 min, and 25% of ammonia water is added to complex and remove the cuprous oxide nucleus, and then 0.5 mol / L of nitric acid is added to react at 10° C. to remove the copper produced by the disproportionation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com