Preparation method for bi-metal composite t-branch pipe

A tee and bimetal technology, which is applied to the preparation of bimetal composite tee and the field of tee preparation, can solve the problems of unfavorable popularization and application, long process flow, complicated process, etc., to achieve broad market prospects and reduce production. Cost, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

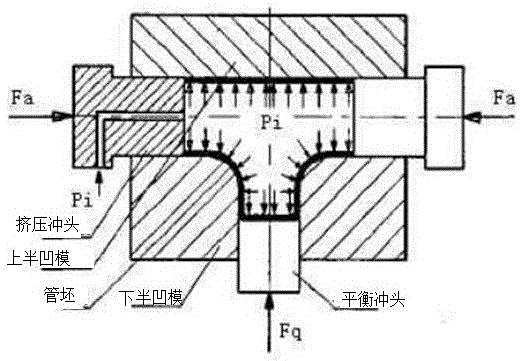

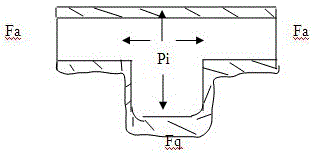

[0012] Example 1: A method for preparing a bimetal composite tee pipe, the method comprising the following steps: 1) preparing two inner and outer metal pipes of different materials to fit together; 2) placing the fitted metal pipes in a mold of a tee machine; 3) Inject liquid into the inner pipe, the liquid is pure water; 4) Open the mold of the three-way machine, provide the internal pressure Pi through the pressurization system of the equipment, and squeeze the pipe through the synchronous centering movement of the two horizontal side cylinders of the hydraulic press For the billet, the left and right oil cylinders provide pressure Fa, and the upper oil cylinder provides the balance force Fq at the end of the branch pipe. After the tube is squeezed, the volume becomes smaller, and the pressure of the liquid in the tube increases with the volume of the tube. Whether to pressurize or not can be determined according to the compounding and deformation of the tube billet), as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com