Bagged high-viscosity asphalt as well as production method and device thereof

A high-viscosity asphalt, production device technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of long production cycle, low relative efficiency, material aging, etc., and achieve advanced production technology, increased polarity, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

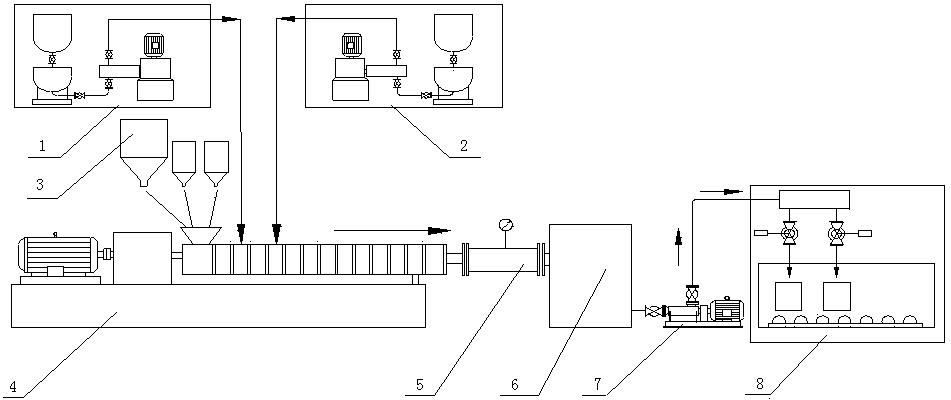

[0030] The production process of the present invention is as figure 1 shown.

[0031] Below further illustrate the present invention by embodiment:

[0032] 1. A bagged high-viscosity asphalt, which is composed of the following components in parts by weight: 85 parts of road asphalt; 8 parts of SBS; 5 parts of petroleum resin; 5 parts of aromatic oil (or rubber oil) (or base oil); polyethylene wax (or microcrystalline wax) 3 parts; antioxidant 1.0 part;

[0033] 2. The production equipment is ordered according to the following requirements:

[0034] Twin-screw extruder or reciprocating single-screw extruder 4 Purchase from the market, asphalt heating and weighing system 1, aromatic oil (or rubber oil) heating and weighing system 2 powder material weighing system 3 temperature, pressure regulator 5. Finished product tank 6, screw pump 7, filling and weighing system 8, according to the production capacity of twin-screw extruder or reciprocating single-screw extruder 4, by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com