Method for extracting micro-fine-particle iron ore concentrate from tailings obtained after primary iron separation

A technology of iron concentrate and microfine particles, which is applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of improved recovery rate, high economic benefits, and friendly operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

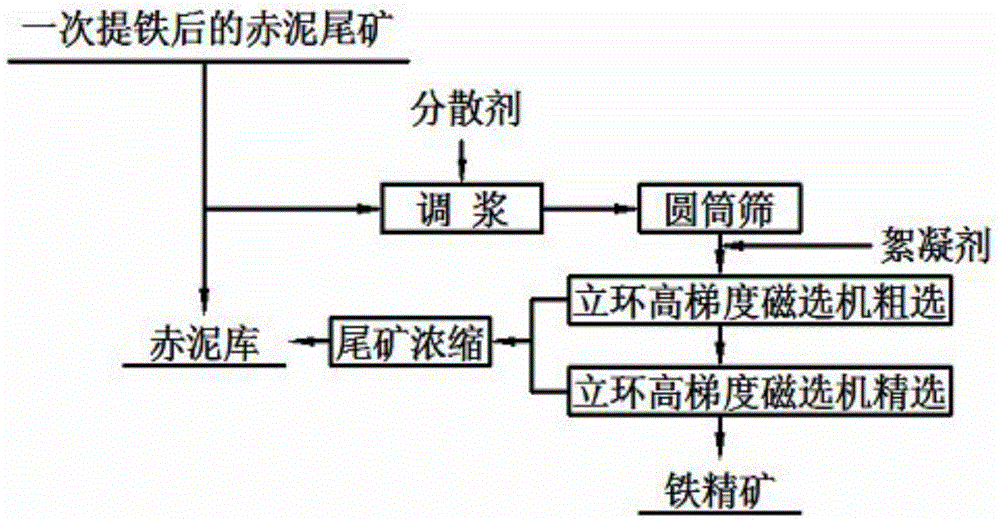

[0030] An example of the method for extracting microfine grain iron ore concentrate from primary iron dressing tailings described in the present invention, comprises the following steps:

[0031] Short-circuit the pipeline before the tailings are sent to the thickening workshop by the underflow of the iron thickening machine, and the tailings are transported to the slurry tank of the iron processing plant through the pipeline Φ5000×5500mm. Add NSF type dispersant to the dry ore, and then use the hydraulic pressure difference on the slurry tank to make the red mud slurry flow to the cylindrical sieve by itself, and the sieve residue with a particle size greater than 500 μm is discharged into the tailings thickener as tailings, and the red mud with a particle size of less than 500 μm Enter DLS-250 vertical-ring pulsating high-gradient magnetic separator for rough separation, the magnetic field strength is 1-2T, and the iron ore concentrate obtained from the rough selection enters...

Embodiment 2

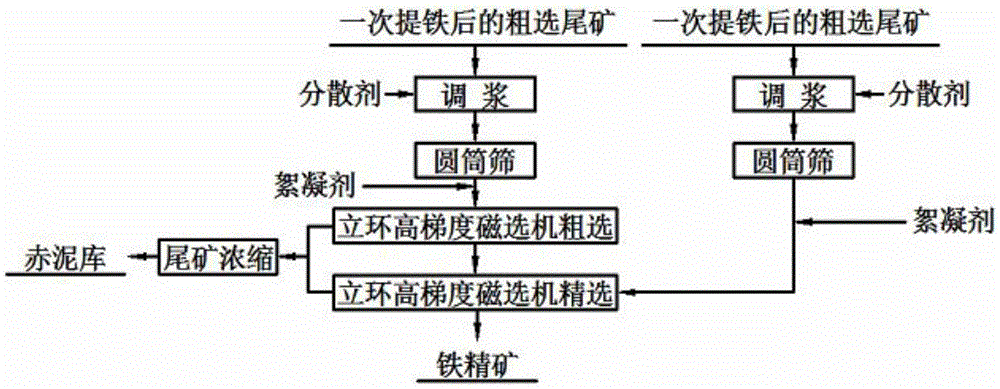

[0033] Another example of the method for extracting microfine grain iron concentrate from the primary iron dressing tailings of the present invention comprises the following steps:

[0034]Short-circuit the pipeline that transports the tailings to the thickener from the primary iron extraction coarse and fine-tuning magnetic separator through the pipeline, and use the pipeline to transport the rough and fine-tuning tailings to the slurry tank of the iron dressing plant Φ5000×5500mm, and adjust the slurry During the process, 10-25g / t of dry ore is added with NSF type dispersant, and then the red mud slurry is automatically flowed to the cylindrical sieve by using the hydraulic pressure difference on the slurry tank, and the sieve residue with a particle size greater than 500 μm is discharged into the tailings denser as tailings. machine, the rougher tailings red mud with a particle size of less than 500μm enters the DLS-250 vertical ring pulsating high gradient magnetic separato...

Embodiment 3

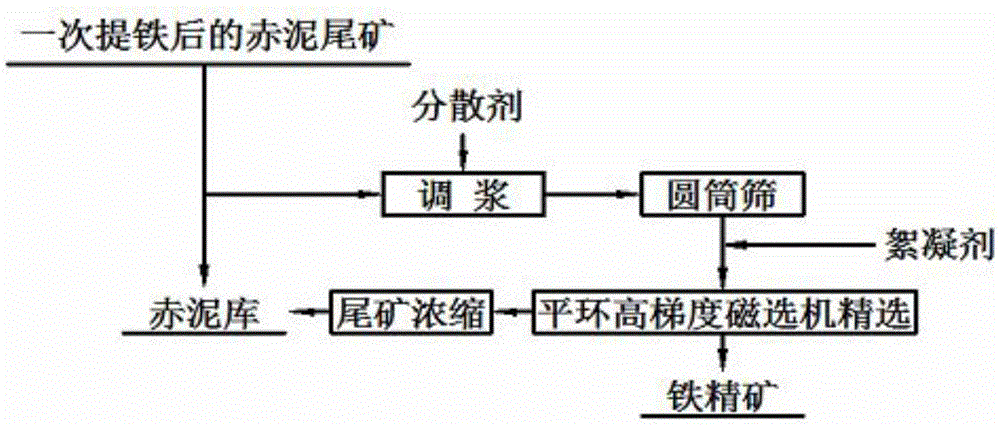

[0036] Another example of the method for extracting microfine grain iron concentrate from the primary iron dressing tailings of the present invention comprises the following steps:

[0037] Short-circuit the pipeline before the tailings are sent to the thickening workshop by the underflow of the iron thickening machine, and the tailings are transported to the slurry tank of the iron processing plant through the pipeline Φ5000×5500mm. Add NSF type dispersant to the dry ore, and then use the hydraulic pressure difference on the slurry tank to make the red mud slurry flow to the cylindrical sieve by itself, and the sieve residue with a particle size greater than 500 μm is discharged into the tailings thickener as tailings, and the red mud with a particle size of less than 500 μm Enter the ZH2600 flat-ring pulsating high-gradient magnetic separator for magnetic separation, the medium field strength is greater than 3.2T, and the magnetic field gradient is greater than 106mm. Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com