Preparation method of nitro-cobalt phthalocyanine/attapulgite composite photo-catalyst

A technology of nitrocobalt phthalocyanine and attapulgite, which is applied in the field of preparation of nitrocobalt phthalocyanine/attapulgite composite photocatalyst, can solve the problem that the catalytic efficiency is not very high, and achieves high yield, high purity, light Good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

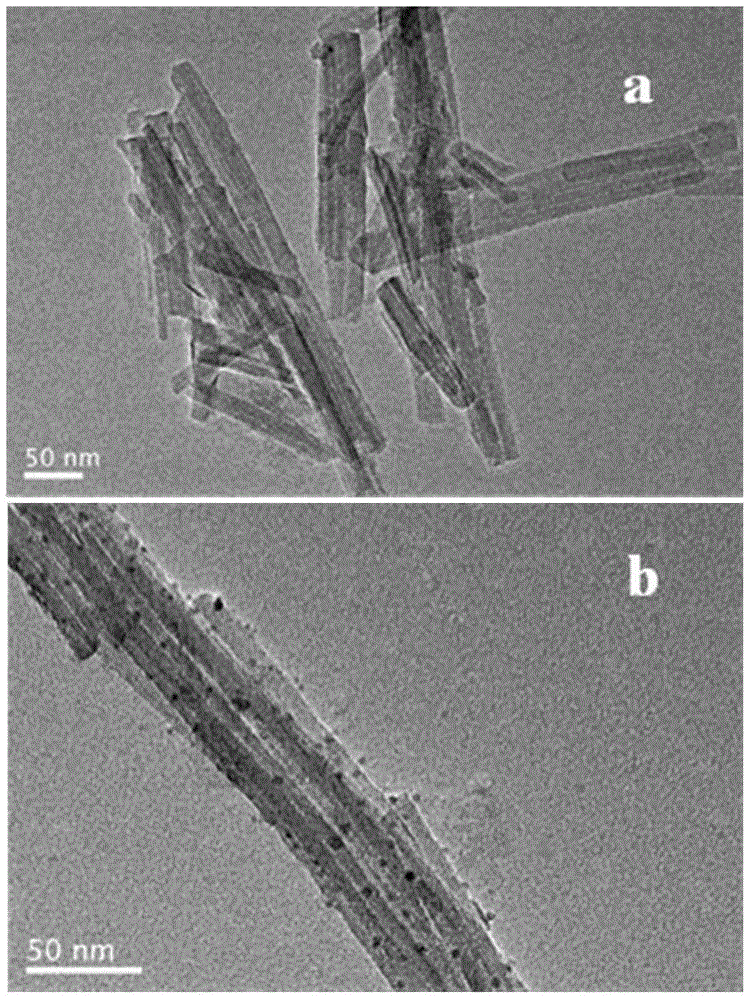

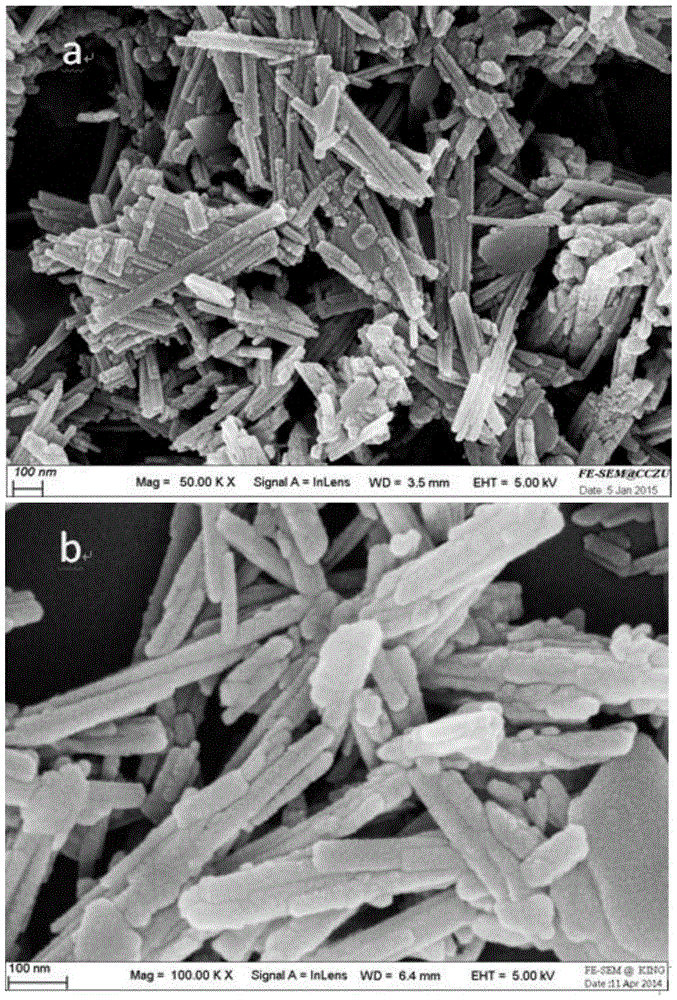

[0026] (1) Pretreatment of attapulgite

[0027] Add 2 g of attapulgite and 200 mL of concentrated nitric acid into a 250 mL three-necked flask, and reflux and condense at 120 ° C for 8 h. HNO removal after natural cooling to room temperature 3 Clear solution, then diluted with deionized water to remove HNO 3 The clear solution was diluted repeatedly, then filtered with a Buchner funnel, and finally dried in an oven.

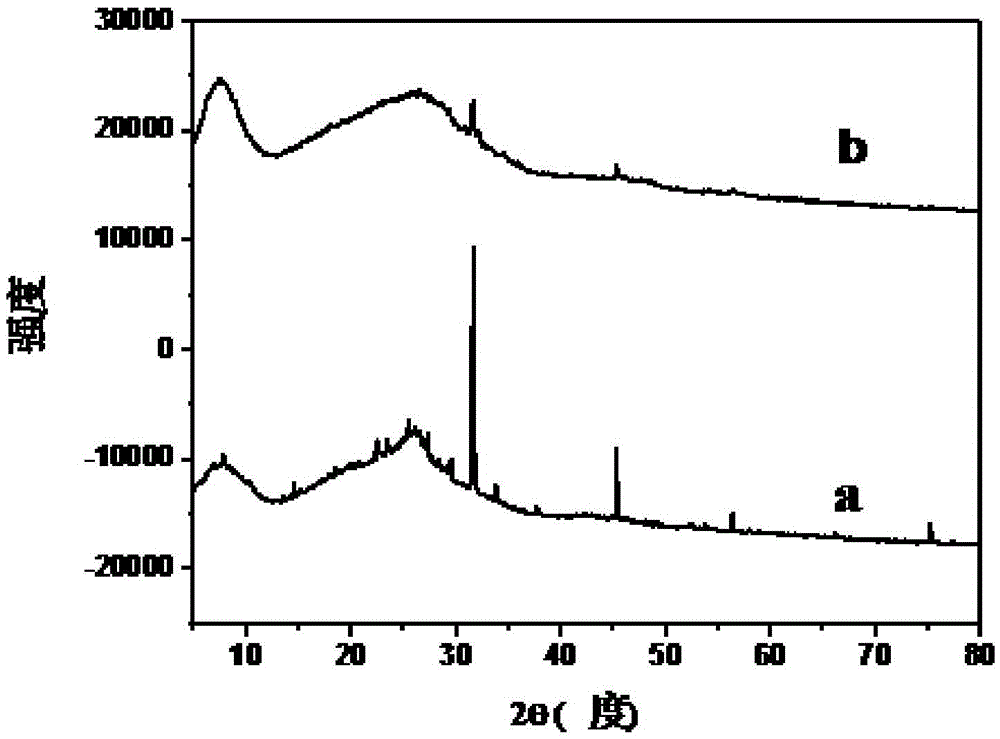

[0028] (2) Preparation of nitrocobalt phthalocyanine

[0029] Weigh 3.820g (4mmol) of 3-nitrophthalonitrile and 1.000g (1mmol) of cobalt chloride into a 250ml three-neck flask, add 100mL of n-amyl alcohol, and then add 3mL of catalyst DBU dropwise. Heated and stirred under the protection of nitrogen, and refluxed to condense, and the reaction was started when the temperature reached 130° C. for 8 hours. After cooling and standing to room temperature, suction filtration was performed with a Buchner funnel, and then rinsed with methanol until the filtrate was c...

Embodiment 2

[0033] (1) Pretreatment of attapulgite

[0034] Add 5 g of attapulgite and 200 mL of concentrated nitric acid into a 250 mL three-necked flask, and reflux at 150 ° C for 10 h. HNO removal after natural cooling to room temperature 3 Clear solution, then diluted with deionized water to remove HNO 3 The clear liquid was diluted repeatedly, then filtered with a Buchner funnel, and finally dried in an oven.

[0035] (2) Preparation of nitrocobalt phthalocyanine

[0036] Weigh 3.820g (4mmol) of 3-nitrophthalonitrile and 1.000g (1mmol) of cobalt chloride into a 250ml three-neck flask, add 100mL of n-amyl alcohol, and then add 7mL of catalyst DBU dropwise. Heated and stirred under the protection of nitrogen, and refluxed to condense, and the reaction was started when the temperature reached 150° C. for 6 h. After cooling and standing to room temperature, suction filtration was performed with a Buchner funnel, and then rinsed with methanol until the filtrate was colorless, then was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com