Sea squirt nano cellulose ultrafiltration membrane as well as preparation method and application of sea squirt nano cellulose ultrafiltration membrane

A nanocellulose and ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology and other directions, can solve the problems of difficult treatment, high preparation cost, high quality of ceramic membrane, etc., and achieves low cost and simple preparation method. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

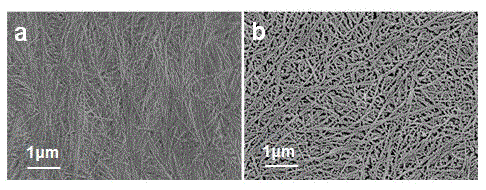

Image

Examples

Embodiment 1

[0016] After dissecting the ascidian, 500 g (wet weight) of the rucksack was treated with 1.5L of 5wt% NaOH solution at 80°C for 24 hours, washed with deionized water until neutral, and then treated twice with alkali in the same way. With 1.5L1.2wt% H 2 o 2 The solution is bleached at 80°C under weakly alkaline conditions (pH 8~9), and 30g of 30%H is added every 3h 2 o 2 , After reacting for 12 hours, rinse with deionized water, dry and crush to obtain 25g of purified product. To prepare sea squirt nanocellulose suspension, 10g sea squirt cellulose was dispersed in 500g 65wt% sulfuric acid and hydrolyzed at 70°C for 2h, the reaction solution was diluted 10 times, centrifuged and washed continuously at 10000rpm until the upper liquid became turbid, and then dialyzed into water until the conductivity remained constant . The suspension was concentrated to a certain concentration by rotary evaporation, and the concentration measured by gravimetric method was 3%.

Embodiment 2

[0018] 20mL of 0.01wt% ascidian nanocellulose aqueous suspension was suction-filtered with a common filter membrane with a pore size of 0.22 μm to prepare a sea squirt nanocellulose ultrafiltration membrane. The ultrafiltration membrane has a thickness of 2 μm and a pore size of ≤30 nm. The ultrafiltration membrane was used to separate bovine serum albumin with a concentration of 10 mg / mL, and the separation rate was 80%. In addition, the ultrafiltration membrane is used for emulsified oil separation test, and the microemulsion of isooctane and water is separated at a mass ratio of 1:99. The ultrafiltration membrane is conducive to demulsification or oil droplet condensation, and effectively intercepts emulsified oil droplets to achieve oil-water separation. Purpose. The separation efficiency of the filter membrane is 90%, and the flow rate is 7710L m -2 h -1 ·MPa -1 .

Embodiment 3

[0020] Take 0.5wt% sea squirt nanocellulose aqueous suspension 3mL, use the 0.22μm pore size ordinary filter membrane, suction filter to make sea squirt nanocellulose ultrafiltration membrane. The ultrafiltration membrane has a thickness of 9 μm and a pore size of ≤30 nm. The ultrafiltration membrane was used to separate bovine serum albumin with a concentration of 10 mg / mL, and the separation rate was 90%. In addition, the ultrafiltration membrane is used for emulsified oil separation test, and the microemulsion of isooctane and water is separated at a mass ratio of 1:99. The ultrafiltration membrane is conducive to demulsification or oil droplet condensation, and effectively intercepts emulsified oil droplets to achieve oil-water separation. Purpose. The separation efficiency of the filter membrane is 99%, and the flow rate is 2100L m -2 h -1 ·MPa -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com