Preparation method of MnO<2>@GCs@MnO<2> composite material

A composite material, graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of cumbersome steps, unfavorable promotion and application, complicated operation, etc., to achieve simple operation, electrical conductivity and cycle stability Good properties and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of sandwich structure MnO 2 GCsMnO 2 The preparation method of composite material, comprises the following steps:

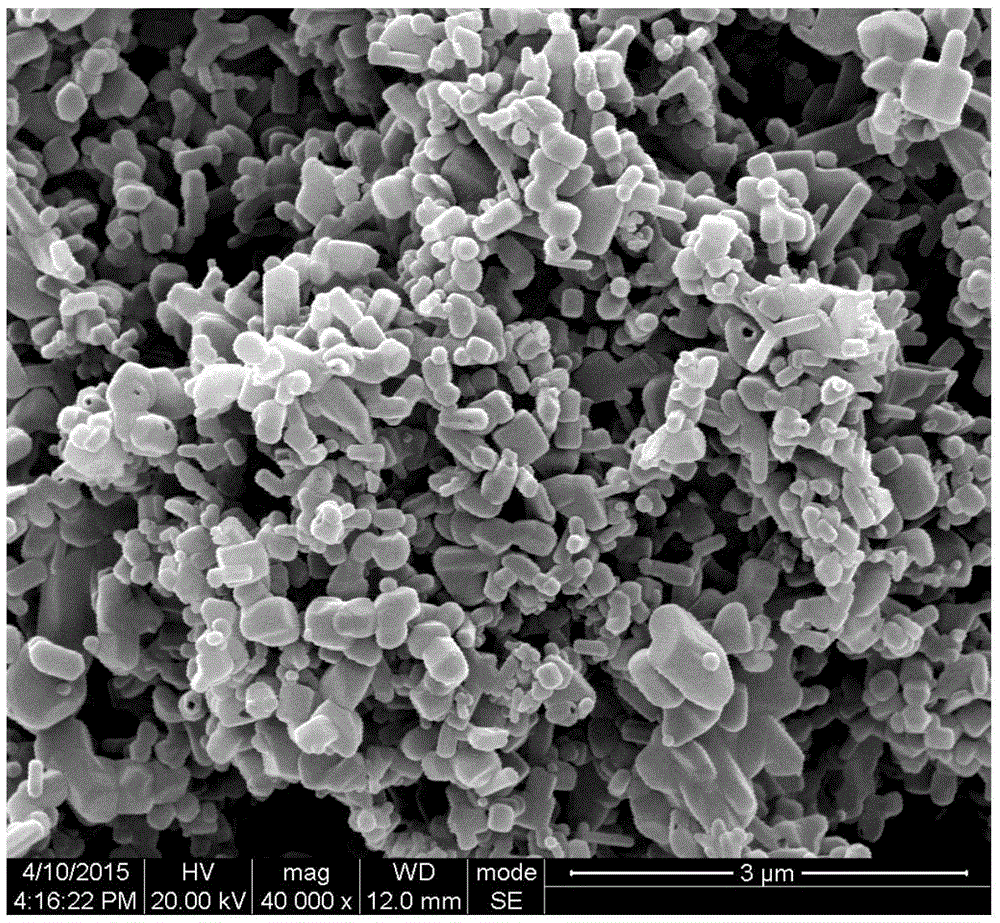

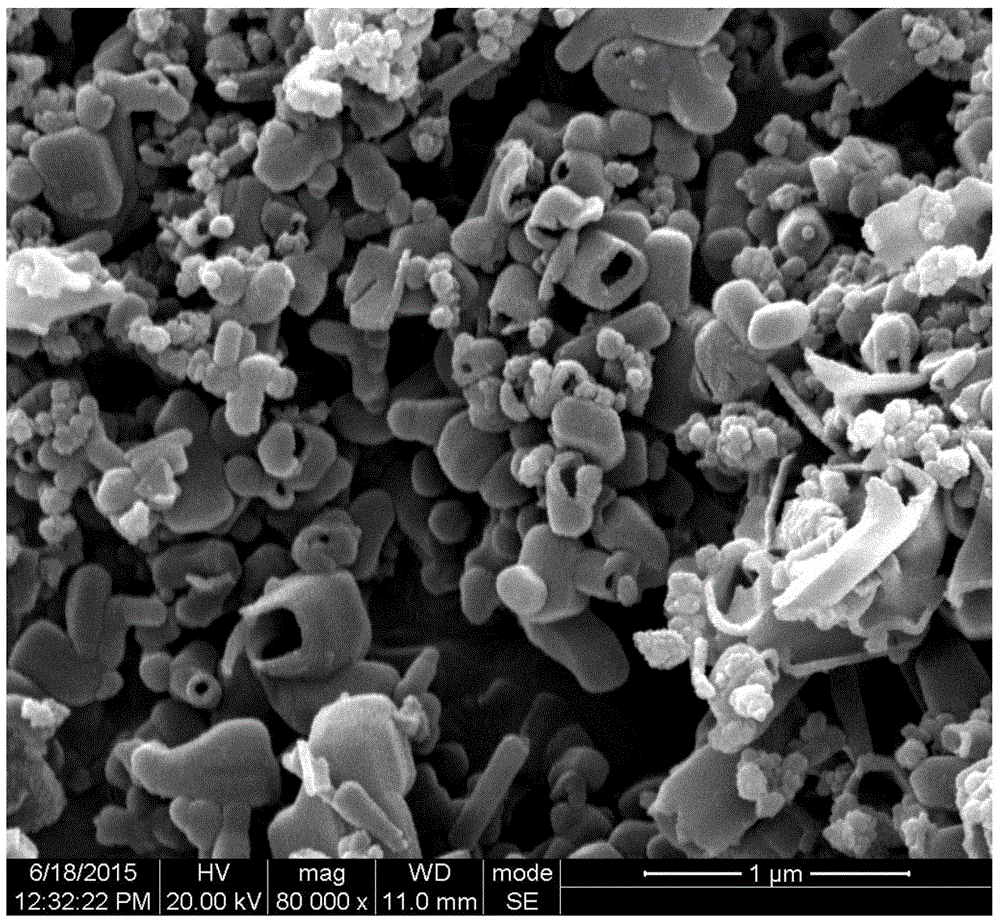

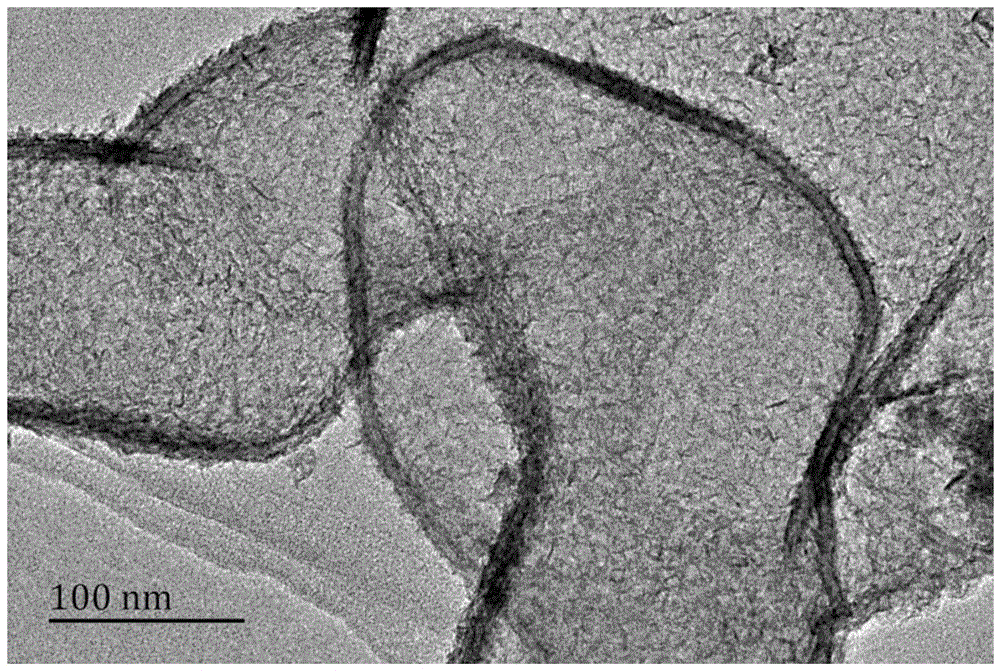

[0026] Step 1, preparing graphene capsules based on chemical vapor deposition equipment: a) spread and disperse nano-zinc oxide particles with a particle size of 10-200 nm in a quartz boat, and put the quartz boat into the middle of the quartz tube of a horizontal heating furnace, Pass inert gas into the quartz tube to discharge the air, then raise the temperature of the horizontal heating furnace to 400-800°C at a heating rate of 3-15°C / min; keep the temperature in the heating furnace at 400-800°C, Feed acetylene gas at a rate of ~50mL / min as a reactant for 30 to 60 min, and graphene nanolayers can be grown in situ on the surface of zinc oxide particles to obtain a graphene / zinc oxide composite material; The composite material of graphene / zinc oxide obtained in the previous step is soaked in 0.1~1mol / L nitric acid for 12~48h to remove zinc oxide ...

Embodiment 1

[0030] A kind of sandwich structure MnO 2 GCsMnO 2 The preparation method of composite material, comprises the following steps:

[0031]Step 1, preparation of graphene capsules: a) 100 mg particle size of 20nm nano-zinc oxide particles is evenly spread and dispersed in the quartz boat, and the quartz boat is placed in the middle of the quartz tube of the horizontal heating furnace, after checking the air tightness, Inject argon gas into the quartz tube at a rate of 80 mL / min for 20 minutes to discharge the air in the quartz tube; then raise the horizontal heating furnace from room temperature to 700 °C at a heating rate of 5 °C / min, and heat the After the temperature stabilizes for 20 minutes, stop feeding argon gas; keep the temperature in the heating furnace at 700°C, and feed acetylene gas into the heating furnace as a reactant at a rate of 50 mL / min for 30 min. After the reaction is completed, stop feeding Inject acetylene, then pass in argon, and cool down to room tempe...

Embodiment 2

[0036] A kind of sandwich structure MnO 2 GCsMnO 2 The preparation method of composite material, comprises the following steps:

[0037] Step 1, preparation of graphene capsules: a) 100 mg particle size of 20nm nano-zinc oxide particles is evenly spread and dispersed in the quartz boat, and the quartz boat is placed in the middle of the quartz tube of the horizontal heating furnace, after checking the air tightness, Inject argon gas into the quartz tube at a rate of 80 mL / min for 20 minutes to discharge the air in the quartz tube; then raise the horizontal heating furnace from room temperature to 700 °C at a heating rate of 5 °C / min, and heat the After the temperature stabilizes for 20 minutes, stop feeding argon gas; keep the temperature in the heating furnace at 700°C, and feed acetylene gas into the heating furnace as a reactant at a rate of 50 mL / min for 30 min. After the reaction is completed, stop feeding Inject acetylene, then pass in argon, and cool down to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com