Pipeline material cloud elastic cutting, labeling and processing automatic guidance system and method

An automatic guidance and pipeline technology, applied in the field of pipeline engineering material preparation optimization system, can solve the problems of inability to meet the needs of flexible processing operations, low equipment data memory capacity, loss, etc., to increase the demand for end-processing guidance and meet the needs of material preparation operations , Strengthen the effect of material preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The technical solution and method of the present invention will be described in detail below in conjunction with the accompanying drawings, in order to fully understand the technical solution and method of the present invention.

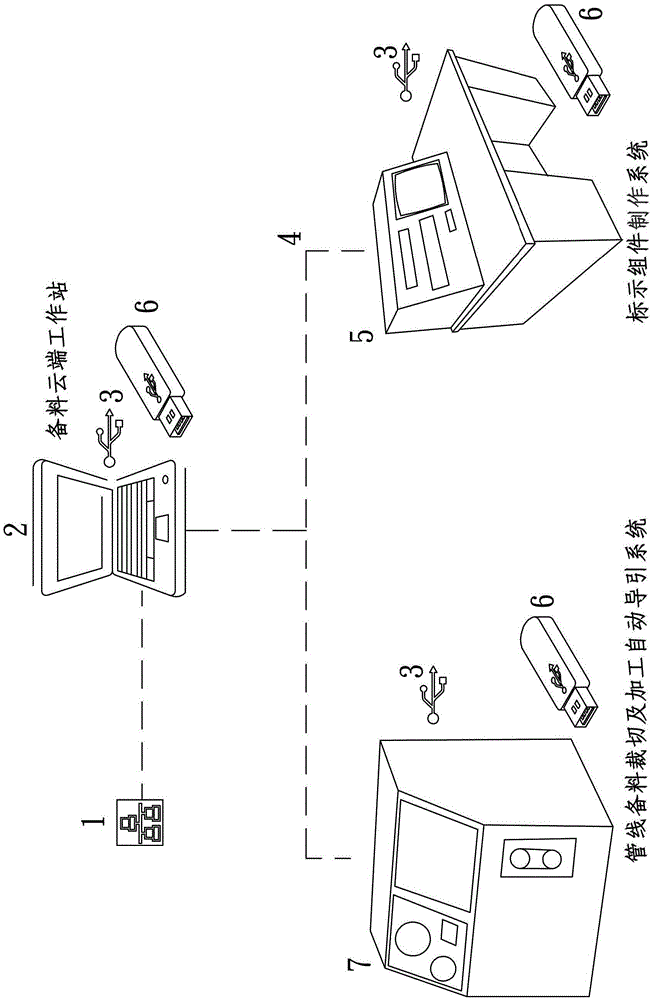

[0080] Such as figure 1 , a cloud-based flexible cutting, labeling and processing automatic guidance system for pipeline materials, including a material preparation cloud workstation 2, a marking component production system 5 and a pipeline material preparation cutting and processing automatic guidance system 7; the material preparation cloud The workstation 2 is electrically connected to the marking component production system 5 and the pipeline material preparation, cutting and processing automatic guidance system 7 respectively through the network connection device;

[0081] The described cloud workstation 2 for preparing materials has an Internet connection interface, a local area network connection interface and a USB access interface; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com