Defect positioning method for condensed laser sensor array based Lamb corrugated plate structure

A laser sensor, intensive technology, applied in the direction of optical testing flaws/defects, instruments, scientific instruments, etc., can solve problems such as large area, unable to meet the detection requirements, poor working conditions, etc., to achieve the effect of improving sensitivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Provide following test embodiment in conjunction with the content of the inventive method:

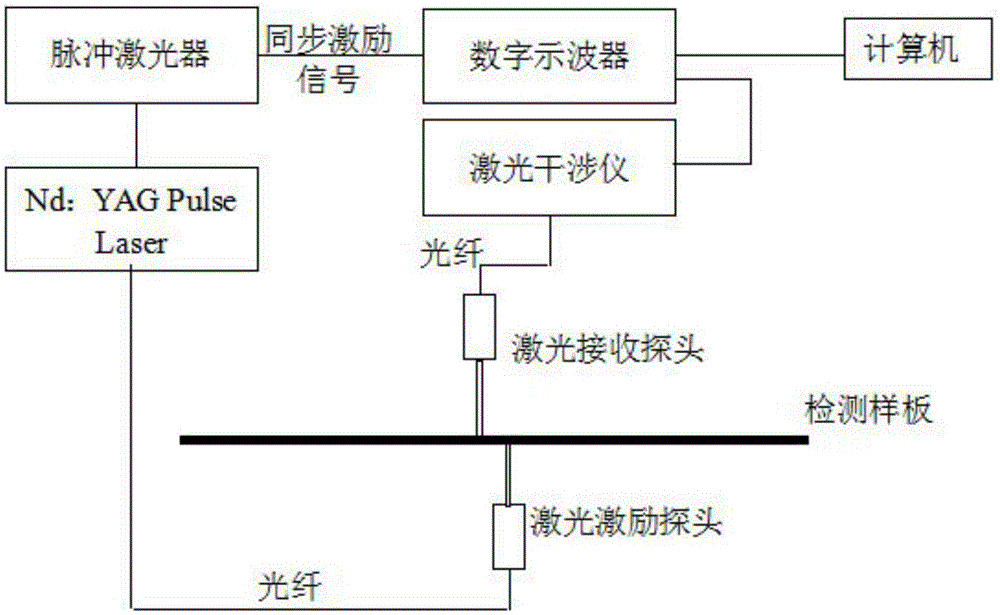

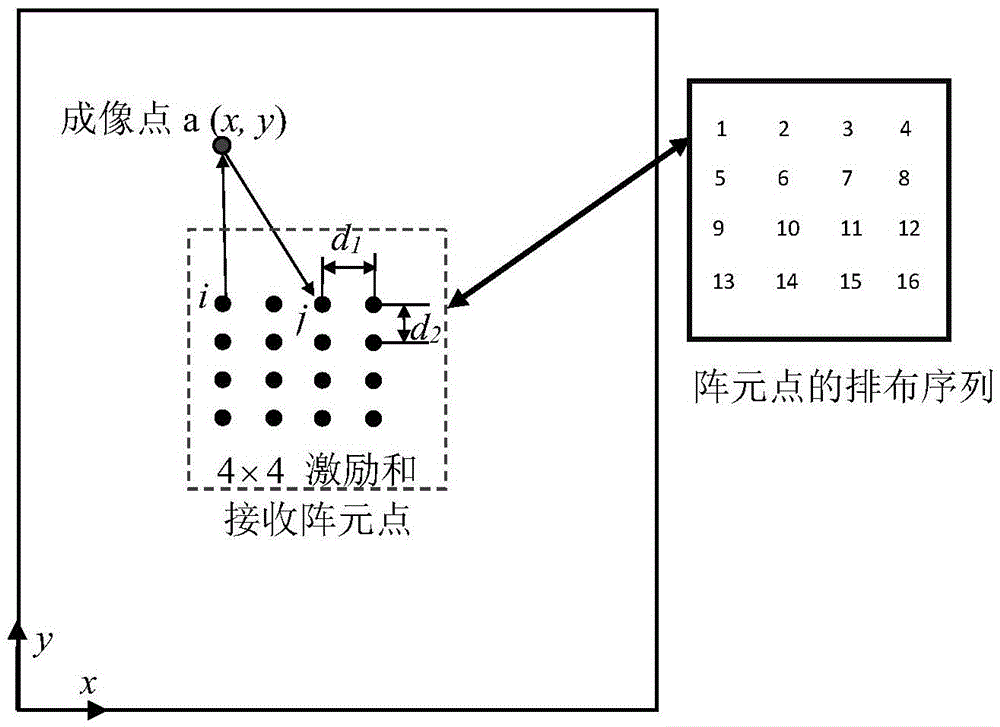

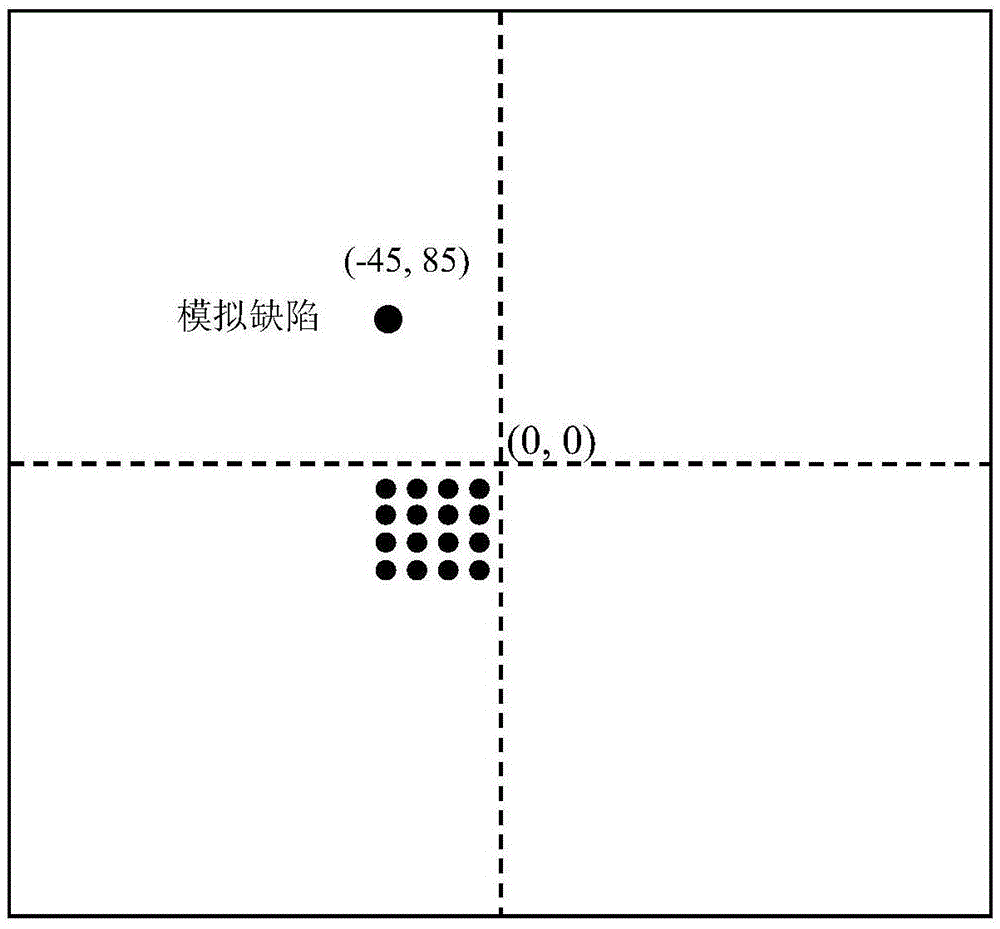

[0041] Use magnets to simulate surface defects on an aluminum plate of 1000mm×1000mm×0.8mm, and the defect size is a cylindrical defect with a radius of 6mm such as image 3 , 16 excitation elements of 4×4 are distributed in the central part of the aluminum plate, the array shape is square, the horizontal spacing and the vertical spacing are both 10mm, the excitation source of the laser is point source excitation, and the radius of the excited light spot is 0.5 mm, since the diameter of the laser excitation probe and the receiving probe itself is greater than 10mm, the distance between the excitation probe and the receiving probe cannot be guaranteed to be 10mm, and the excitation on the same plane will be affected by the air shock wave generated by the laser thermoelastic mechanism on the received signal, so in In this experiment, the method of laser excitation and different-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com