Automobile seat sliding rail lubrication grease and preparation method thereof

A car seat slide rail and grease technology, applied in the direction of lubricating composition, base material, additives, etc., can solve the problems affecting the cleanliness and aesthetics of the car, the long-term lubrication is not very good, and the pollution of cloth and carpets, etc. , to achieve excellent extreme pressure and anti-wear performance, simple and easy-to-control preparation method, and good pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

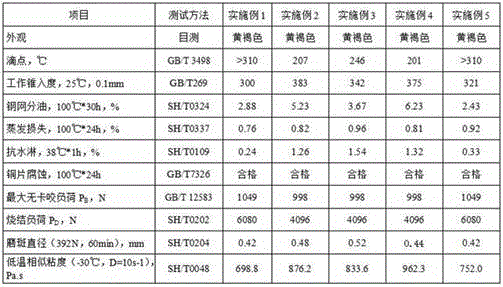

Examples

Embodiment 1

[0019] Put 35kg of polyalphaolefin, 30kg of linear calcium calcium benzene sulfonate with high alkali value into the reactor, stir and heat to 60°C, mix well and add 2kg of dodecylbenzenesulfonic acid, 5kg of water and 1kg of phosphoric acid mixture , stirred at 60°C for 60 minutes, then raised the temperature to 90°C, then added 22.1kg of polyalphaolefin, 1.5kg of boric acid, 2kg12-hydroxystearic acid, and 1.4kg of calcium hydroxide, and continued to heat up to 180°C, and finally Cool down to 90°C for homogeneous sampling and testing.

Embodiment 2

[0021] Put 33kg of sebacate and 32kg of straight-chain calcium calcium benzene sulfonate with high base value into the reactor, stir and heat to 60°C, mix well and add 2kg of dodecylbenzenesulfonic acid, 5kg of water and 3kg of ethanol to mix Liquid, sealed and stirred at 70°C for 60min, then heated to 90°C, then added 20kg sebacic acid ester, 1.6kg sebacic acid, 2.2kg12-hydroxystearic acid, 1.2kg calcium hydroxide, and continued to heat up to 180°C, and finally cooled to 90°C for homogeneous sampling.

Embodiment 3

[0023] Put 34kg of polyalphaolefin and 31kg of branched calcium calcium benzene sulfonate with high alkali value into the reactor, stir and heat to 63°C, mix well and add 2kg of phosphoric acid, 1kg of acetic acid, 5kg of water and 1kg of n-butanol mixed solution, Airtightly stir at 70°C for 60min, then raise the temperature to 100°C, then add 21.1kg of polyalphaolefin, 1.6kg of boric acid, 2kg of stearic acid, and 1.3kg of calcium hydroxide, continue to heat up to 180°C, and finally cool down to 90°C ℃ homogeneous sampling test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com