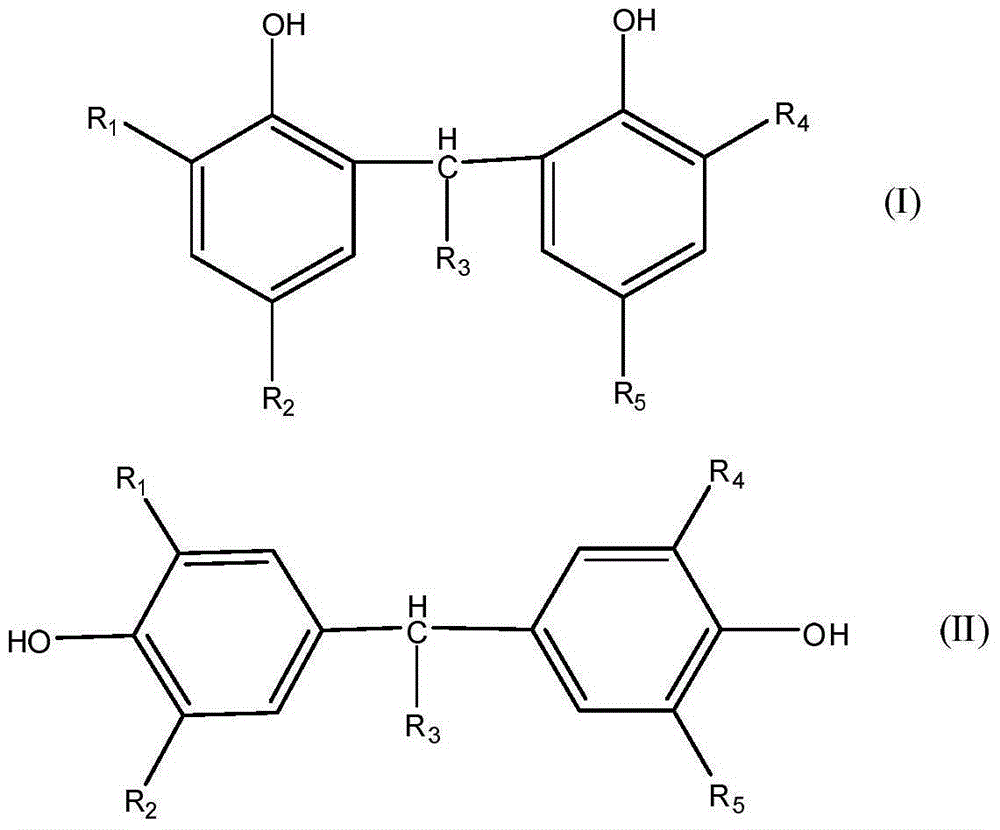

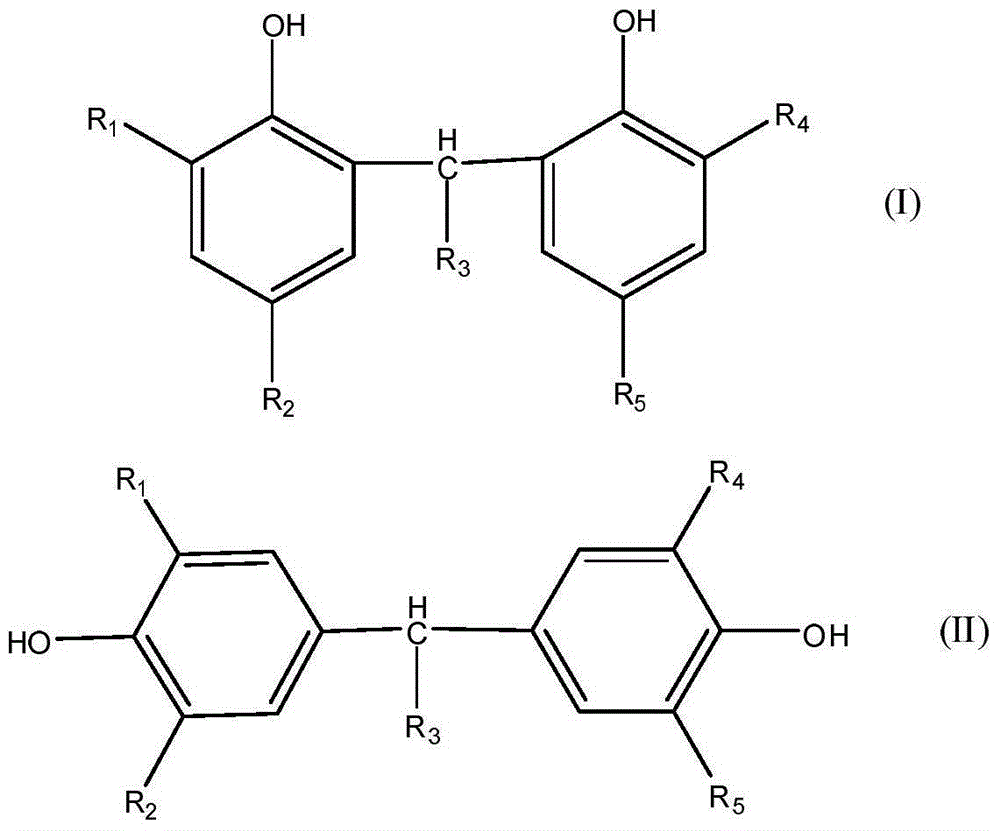

Cleaner production method and use of bisphenol compound anti-oxidant

A clean production and compound technology, applied in the preparation of organic compounds, chemical instruments and methods, lubricating compositions, etc., can solve problems such as unfavorable industrial production, harsh reaction conditions, serious environmental pollution, etc., and achieve scientific and reasonable route design and reaction. The effect of short cycle and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the preparation method of the present invention, the reaction is carried out in a closed reactor, and the reaction system performs condensation reaction in a closed state, effectively avoiding the oxidation of fatty aldehyde and alkylphenol raw materials and the oxidation of bisphenol compound products, and the result is The crude product of bisphenol compound is off-white crystal.

[0042] After the reaction is finished, the solid catalyst needs to be removed. Commonly used methods include but are not limited to: filtration, centrifugal filtration, decantation and other methods to separate the solid catalyst from the desired product. Filter aids such as diatomaceous earth (Celite) can be used to improve separation efficiency.

[0043] A typical application of the bisphenol compound antioxidant of the present invention is as an additive in lubricating oil compositions, but it can also be used in other applications. Further, some embodiments of the present invention ...

Embodiment 1

[0046] Add 78ml of methylal, 36g of 2-tert-butyl-p-cresol (4:1 molar ratio) and 7.2g of clay activated by p-toluenesulfonic acid into a thick-walled pressure-resistant glass bottle with a magnet , reacted at a reaction temperature of 40°C and a reaction time of 3 hours. After the reaction, the reaction product was cooled to room temperature, and the catalyst was separated by suction filtration to obtain a crude reaction product, which was washed to obtain 2,2'-methylene Base-bis(4-methyl-6-tert-butylphenol). The product yield is greater than 75%, and the product purity is greater than 98%.

[0047] The p-toluenesulfonic acid-activated clay used in this embodiment can also be replaced by other acid clays containing free acids and other acid-activated acid clays listed above.

Embodiment 2

[0049] 2-tert-butyl p-cresol 109g, paraformaldehyde 10g (molar ratio is 2:1) and p-toluenesulfonic acid activated clay 10.9g are added in a thick-walled pressure-resistant glass bottle with a magnet, in The reaction temperature is 100° C., and the reaction time is 1 hour. After the reaction, the aftertreatment of the reaction product is the same as in Example 1. The product yield is greater than 75%, and the product purity is greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com