Aluminum alloy casting waste gas treating device and method

A waste gas treatment device and treatment method technology, which is applied in the field of aluminum alloy smelting and low-pressure casting, to achieve the effects of high absorption and purification efficiency, large processing capacity and low working cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

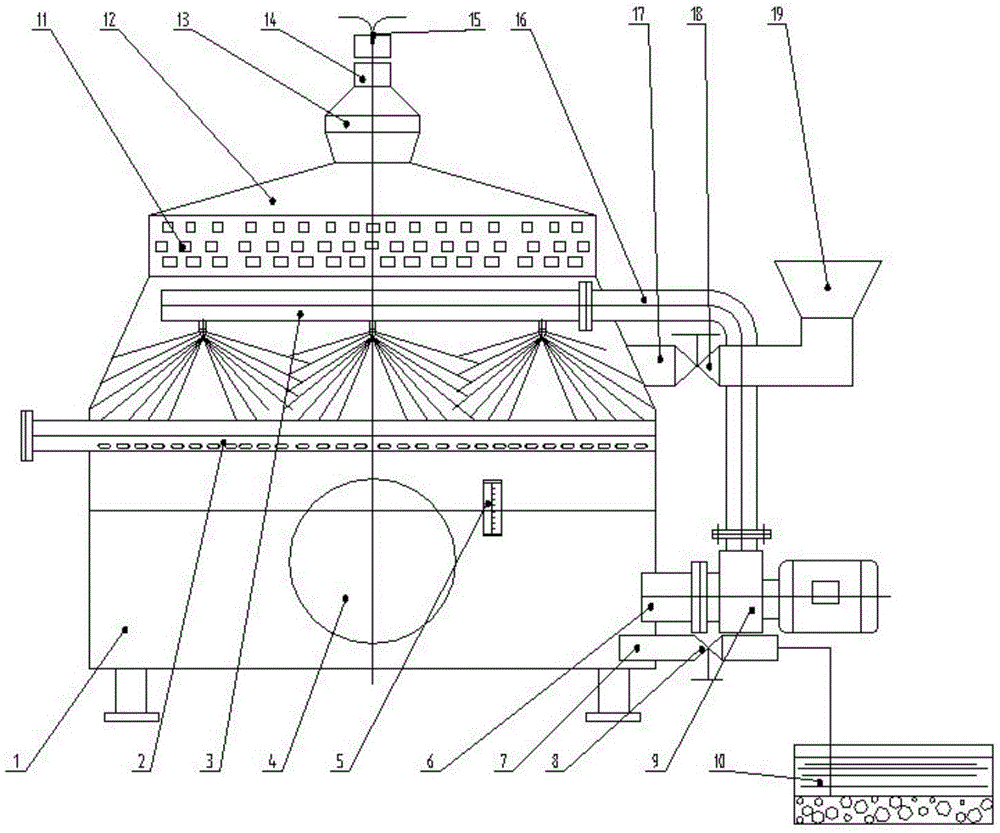

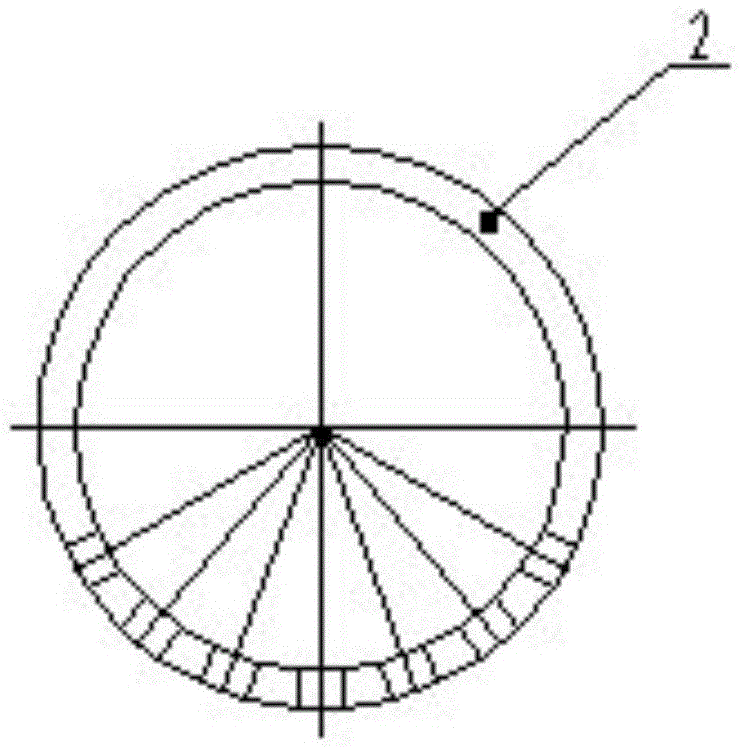

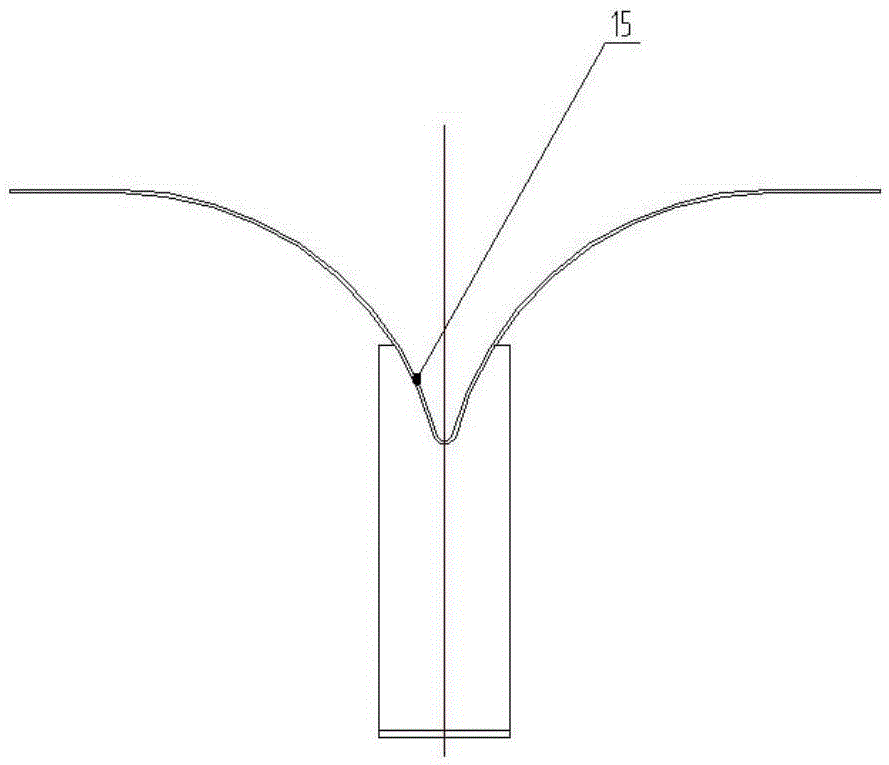

[0015] See figure 1 , figure 2 , image 3 , an aluminum alloy casting exhaust gas treatment device, the present invention is characterized in that: an inlet muffler pipe 2 is welded and introduced into the middle and upper part of the pagoda-shaped spray water tank 1; a U-shaped spiral liquid curtain spray is respectively connected and introduced into the upper part of the inlet muffler pipe 2 System 3 and feeding pipe 17, feeding pipe 17 is connected together with feeding hopper 19 through feeding valve 18; Manhole cover 4 and liquid level indicator 5 are respectively installed in the lower part of pagoda type spray water tank 1, and is connected with The return pipe 6, the return pipe 6 is introduced into the upper part of the pagoda-shaped spray water tank 1 through the reinforced polypropylene centrifugal pump 9 and its outlet pipeline 16, and is connected with the U-shaped spiral liquid curtain spray system 3 to form an internal circulation pipeline; A drain line 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com