Preparation method of Non-thermal physically preserved water chestnut

A non-thermal, water chestnut technology, applied in the preservation of fruits and vegetables, preservation of fruits/vegetables by radiation/electrical treatment, food preservation, etc., can solve the problems of water chestnut color, taste and nutritional value, hidden dangers of food safety, etc., to avoid food Potential safety hazards, guarantee of taste and nutritional value, and effect of color protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

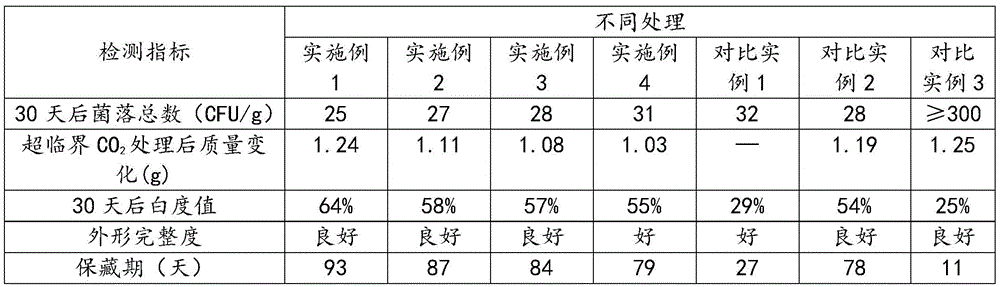

Examples

Embodiment 1

[0025] (1) Selection and pre-treatment: select fresh water chestnuts without rot and thin skin, and cut off the tail pedicles.

[0026] (2), cleaning: wash the water chestnuts with clear water, then put them into an ultrasonic cleaning device and clean them with ultrapure water for 1.5 hours.

[0027] (3), slice: cut the water chestnut into 10mm thin slices after peeling.

[0028] (4), soaking: the water chestnuts after the above-mentioned pretreatment are immersed in ultrapure water to isolate oxygen.

[0029] (5), extraction: 50g of water chestnut slices are packed into the barrel, then put into the extraction kettle, the selected extraction temperature is 43°C, the extraction pressure is 13MPa, the separation temperature is 43°C, the extraction time is 60min, CO 2 The flow rate is 10L / min, the entraining agent is 8% ethanol with a molar fraction of 18% of the weighted water chestnut mass, and ultrasonic vibration is carried out to strengthen the supercritical CO 2 During ...

Embodiment 2

[0035] (1) Selection and pre-treatment: select fresh water chestnuts without rot and thin skin, and cut off the tail pedicles.

[0036] (2) Cleaning: wash the water chestnuts with clear water, then put them into an ultrasonic cleaning device and clean them with ultrapure water for 1 hour.

[0037] (3), slice: cut the water chestnut into 8mm thin slices after peeling.

[0038] (4), soaking: the water chestnuts after the above-mentioned pretreatment are immersed in ultrapure water to isolate oxygen.

[0039] (5), extraction: 50g water chestnut slices are loaded into the barrel, then put into the extraction kettle, the selection extraction temperature is 40°C, the extraction pressure is 11MPa, the separation temperature is 40°C, the extraction time is 45min, CO 2 The flow rate is 8L / min, the entraining agent is 15% of the weighted water chestnut mass, and the entraining agent is 6% ethanol with a molar fraction. 2 During the extraction process, the ultrasonic frequency is 18KHz...

Embodiment 3

[0045] (1) Selection and pre-treatment: select fresh water chestnuts without rot and thin skin, and cut off the tail pedicles.

[0046] (2) Cleaning: wash the water chestnuts with clear water, then put them into an ultrasonic cleaning device and clean them with ultrapure water for 1 hour.

[0047] (3), slice: cut the water chestnut into 8mm thin slices after peeling.

[0048] (4), soaking: the water chestnuts after the above-mentioned pretreatment are immersed in ultrapure water to isolate oxygen.

[0049] (5), extraction: 50g water chestnut slices are loaded into the barrel, then put into the extraction kettle, the selection extraction temperature is 40°C, the extraction pressure is 10MPa, the separation temperature is 40°C, the extraction time is 30min, CO 2 The flow rate is 8L / min, the entraining agent is 15% of the weighted water chestnut mass, and the entraining agent is 6% ethanol with a molar fraction. 2 During the extraction process, the ultrasonic frequency is 18KHz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com