Substrate processing method, substrate processing apparatus, method for manufacturing semiconductor device, and recording medium

一种处理方法、处理容器的技术,应用在半导体/固态器件制造、电气元件、涂层等方向,达到提高制造产能、提高特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

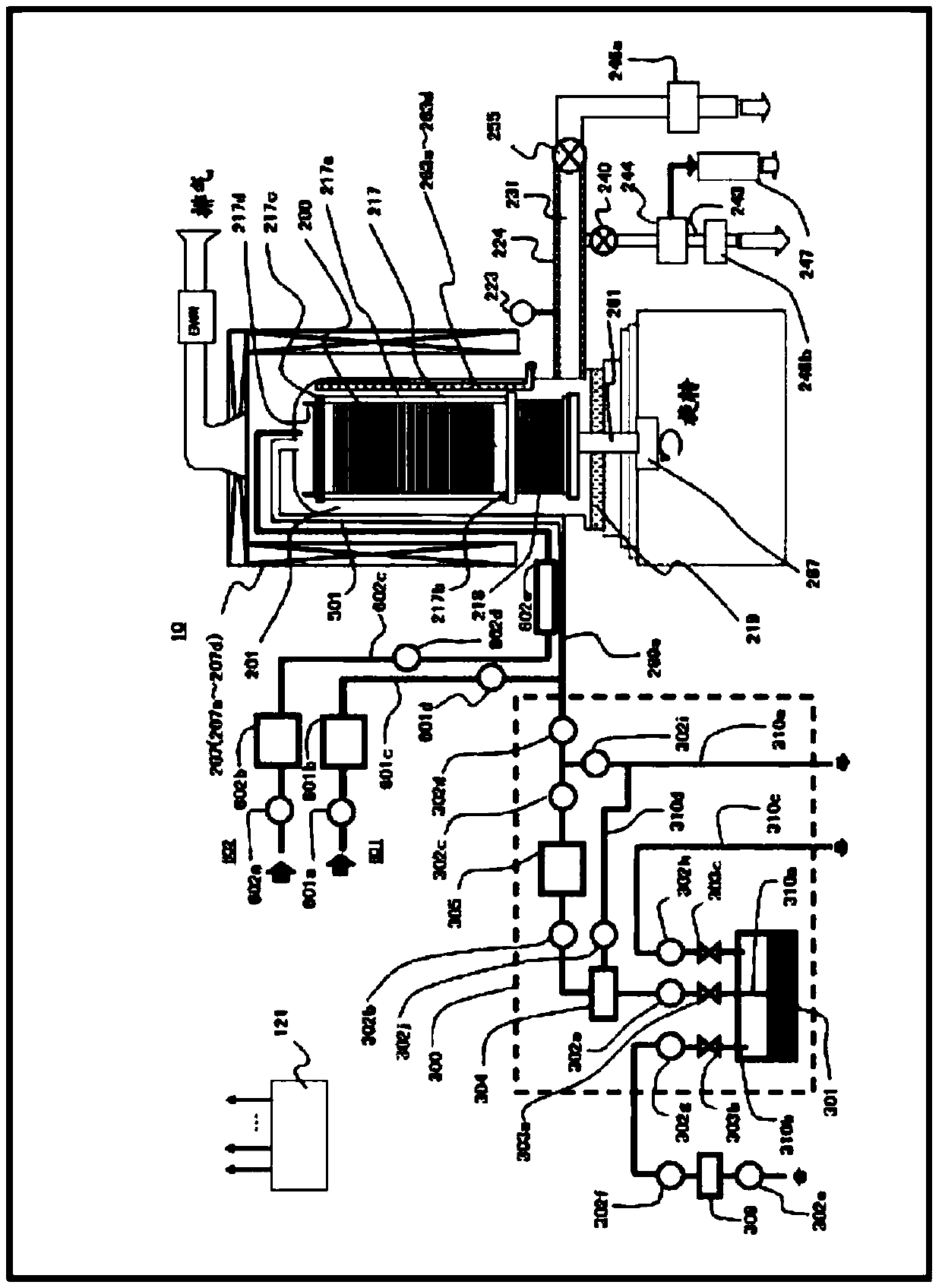

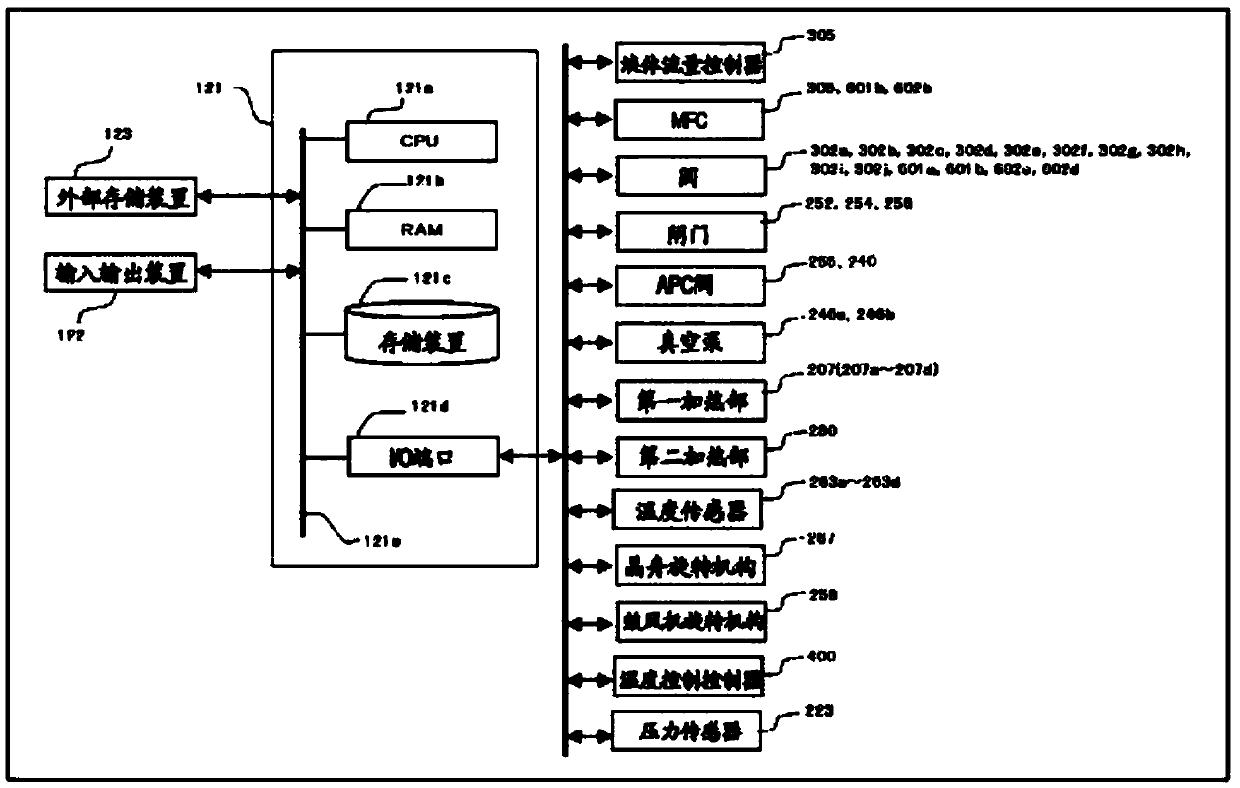

[0044] Hereinafter, a first embodiment which is one of preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0045] (1) Structure of the substrate processing device

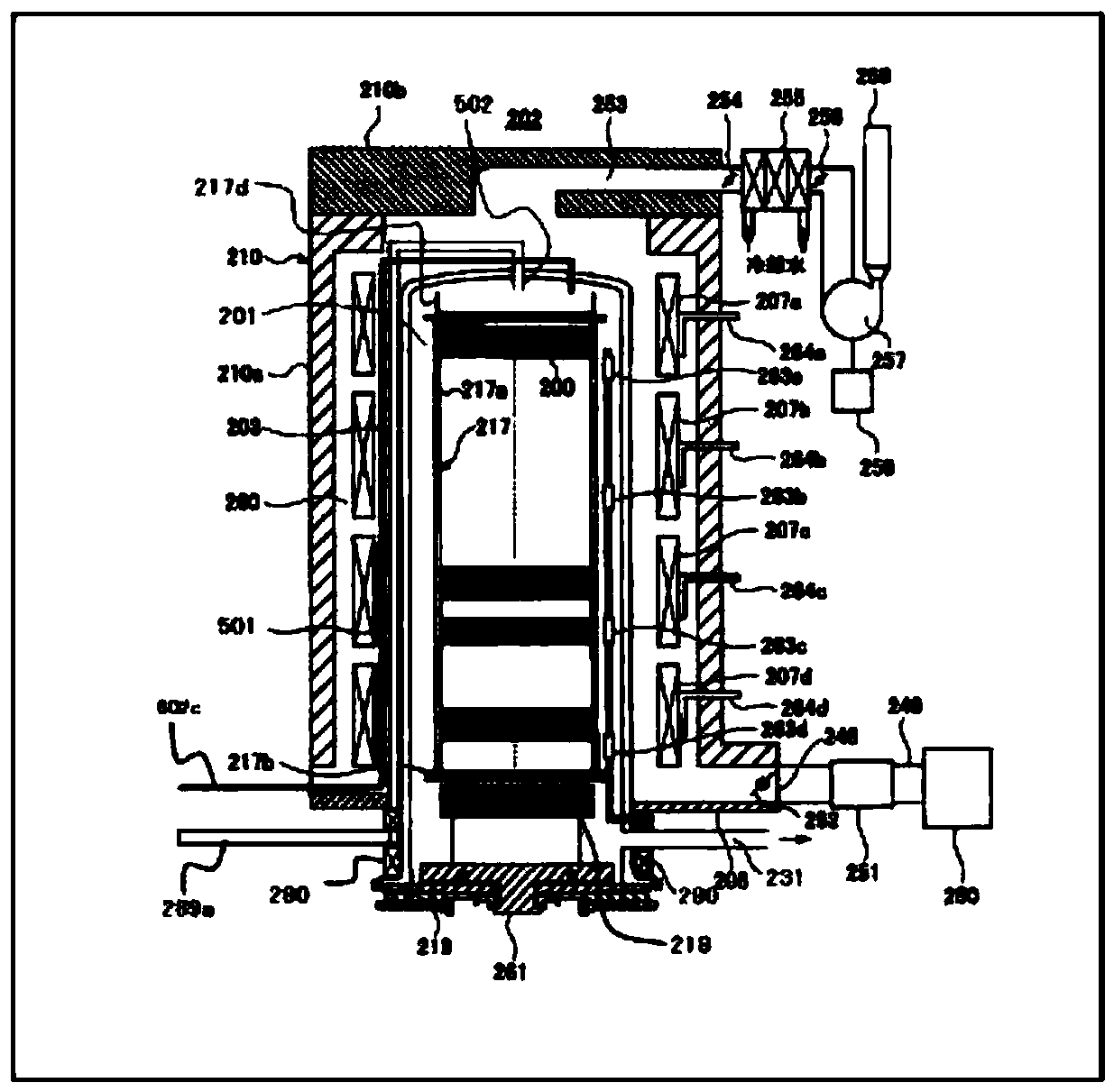

[0046] First, the main use figure 1 and figure 2 The structure of the substrate processing apparatus according to this embodiment will be described. figure 1 It is a schematic configuration diagram of the substrate processing apparatus according to the present embodiment, and shows the processing furnace 202 in vertical section. figure 2 It is a schematic longitudinal sectional view of the processing furnace 202 included in the substrate processing apparatus according to this embodiment.

[0047] (processing container)

[0048] figure 1 As shown, the processing furnace 202 includes a processing container (reaction tube) 203 . The processing container 203 is made of, for example, quartz (SiO 2 ) or silicon carbide (SiC) and other heat-resistant materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com