Preparation method of cathode material, cathode material, and battery

A positive electrode material and iron source technology, applied in the field of batteries, can solve the problems of limited commercial application, low ion and electronic conductivity, etc., achieve excellent cycle performance and rate performance, low production cost, and reduce production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

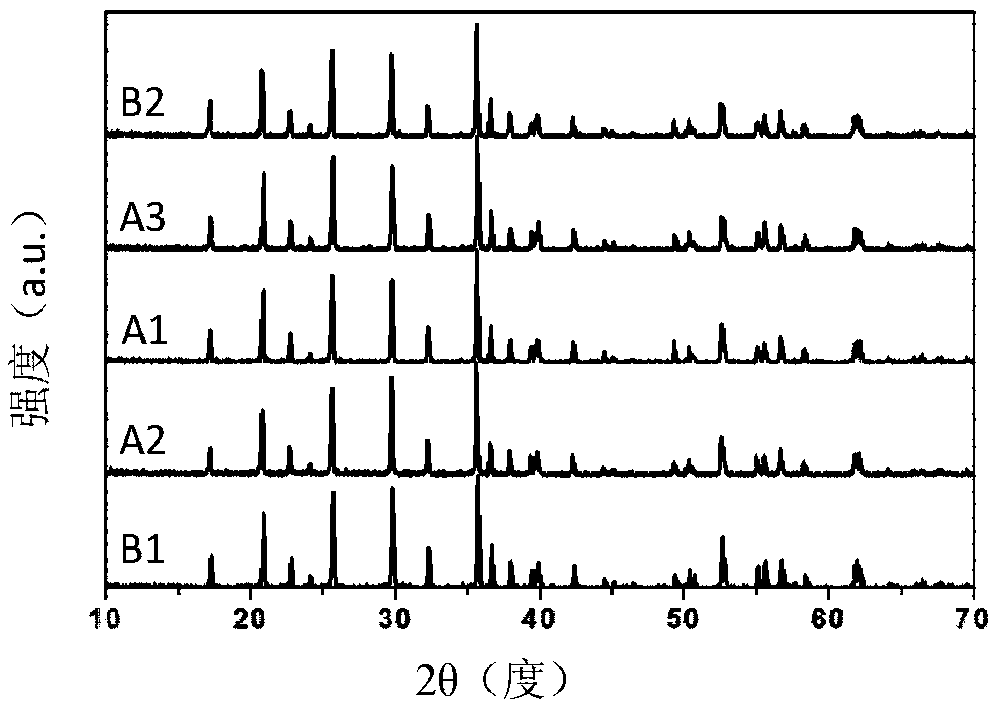

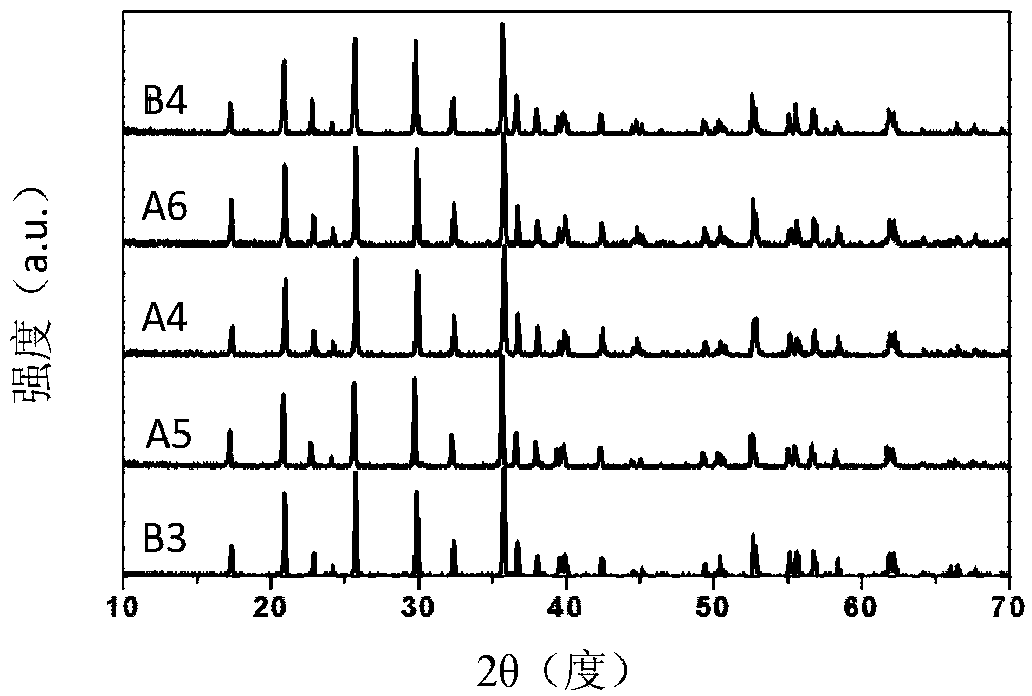

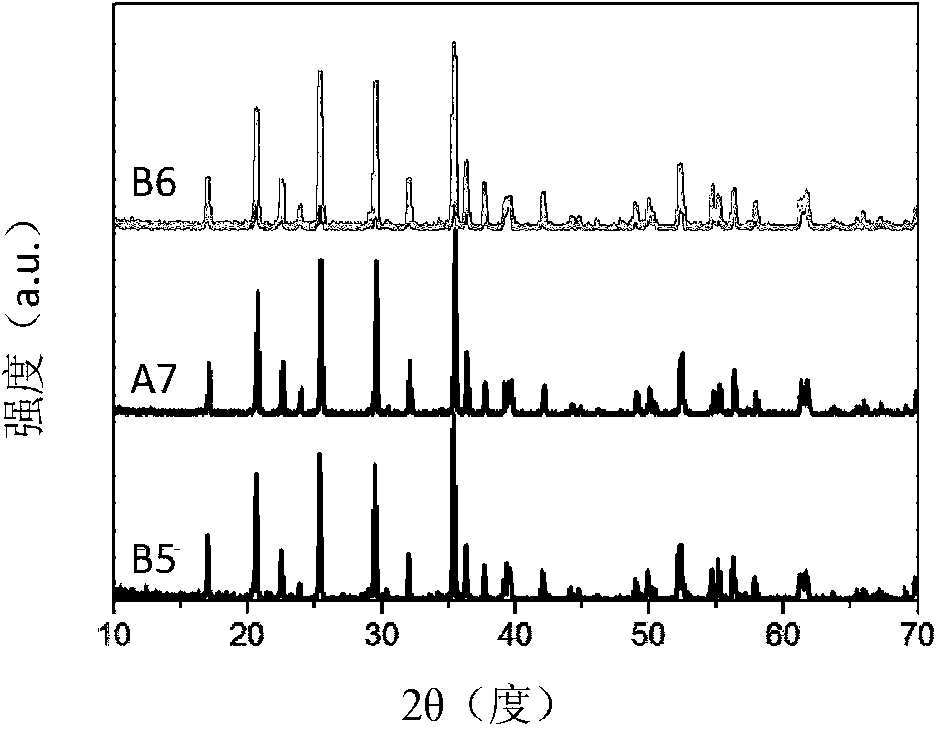

Image

Examples

preparation example Construction

[0041] The present invention proposes a preparation method of a positive electrode material, and the preparation method has the following steps:

[0042] The lithium source, the manganese source, the iron source, and the phosphorus source are mixed according to the material ratio of Li, Mn, Fe, and P of 1:x:1-x:1, wherein 0≤x<1, and the iron source includes the first An iron source and a second iron source, wherein the material ratio of the first iron source and the second iron source ranges from 2:8 to 8:2;

[0043] The mixed product is calcined in an inert atmosphere to obtain a calcined product, the calcination temperature is 300-550°C, and the calcination time is 2-20h;

[0044] The pre-sintered product is mixed with the carbon source and sintered in an inert atmosphere, the sintering temperature is 600-900 DEG C, and the sintering time is 2-20 hours.

[0045] The preparation method of the present invention includes two situations, corresponding to the preparation method ...

Embodiment approach 1

[0048] When x=0, the present invention is a lithium iron phosphate (LiFePO 4 ) preparation method, comprising the following steps:

[0049]The lithium source, the iron source, and the phosphorus source are mixed according to the material ratio of Li, Fe, and P at 1:1:1, wherein the iron source includes a first iron source and a second iron source, and the first iron source and The material ratio range of the second iron source is 2:8-8:2;

[0050] The mixed product is calcined in an inert atmosphere to obtain a calcined product, the calcination temperature is 300-550°C, and the calcination time is 2-20h;

[0051] The pre-sintered product is mixed with the carbon source and sintered in an inert atmosphere, the sintering temperature is 600-900 DEG C, and the sintering time is 2-20 hours.

[0052] The iron source in the present invention is ferrous oxalate, ferric oxalate, ferrous acetate, ferric acetate, ferrous nitrate, ferric nitrate, ferric phosphate, ferric oxide, ferrous ...

Embodiment approach 2

[0070] When 0x Fe 1-x PO 4 ) preparation method, comprising the following steps:

[0071] The lithium source, the manganese source, the iron source, and the phosphorus source are mixed according to the material ratio of Li, Mn, Fe, and P 1:x:1-x:1, wherein 0<x<1, wherein the iron source includes the first iron source and a second iron source, the material ratio of the first iron source and the second iron source ranges from 2:8 to 8:2;

[0072] Drying, pre-sintering the dried product in an inert atmosphere to obtain a pre-sintering product, the pre-sintering temperature is 300-550 °C, and the pre-sintering time is 2-20 h;

[0073] The pre-sintered product is mixed with the carbon source and sintered in an inert atmosphere, the sintering temperature is 600-900 DEG C, and the sintering time is 2-20 hours.

[0074] The manganese source in this embodiment is at least one of manganese chloride, manganese oxalate, manganese sulfate, manganese nitrate, manganese trioxide, manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com