Waste concrete low-temperature heat treatment regenerated active micropowder and preparation method thereof

A waste concrete, low-temperature heat treatment technology, applied in the field of building materials, can solve the problems of incorporation, high thermal activation temperature and mechanical grinding manufacturing cost, difficult to popularize and apply, etc., achieve uniform particle shape and particle size index, and improve surface dispersion effect , The effect of convenient grinding treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

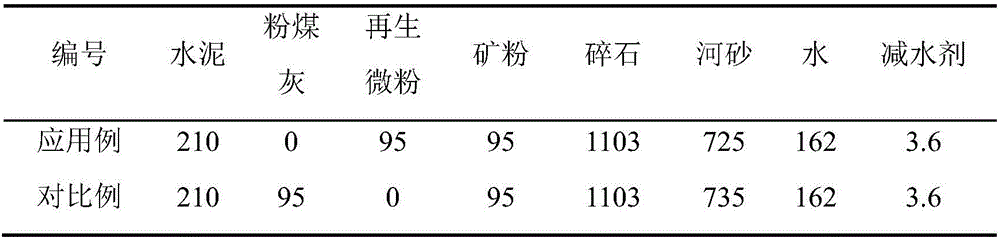

Examples

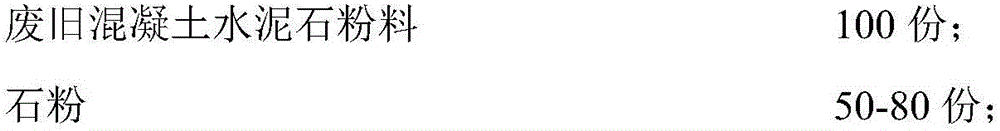

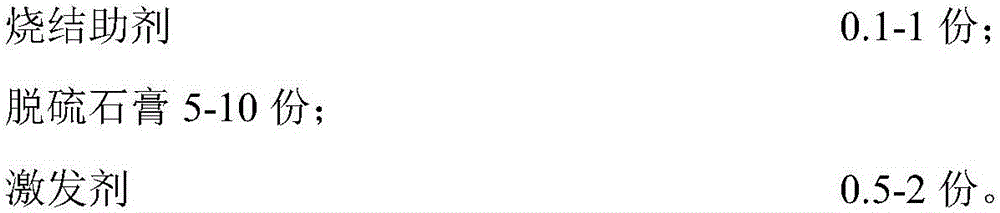

Embodiment 1

[0030] A low-temperature heat treatment of waste concrete regenerated active micropowder, which is composed of 100 parts by weight of waste concrete cement stone powder, 70 parts by weight of stone powder, 0.8 parts by weight of sintering aid, 7 parts by weight of desulfurized gypsum, and 0.8 parts by weight of an activator; wherein the activator consists of 72wt% modified bentonite, 6wt% polyoxyethylene sorbitan monostearate, 8wt% sodium alginate, 5wt% soda ash and 9wt% alkali lignin are mixed; the sintering aid is zinc sulfate.

[0031] The preparation steps of the waste concrete low-temperature heat treatment regenerated active micropowder are as follows: 1) Take waste concrete or waste mortar as raw material, first crush it once with a crusher to obtain recycled coarse aggregate with a particle size of less than 19 mm, and then perform secondary crushing to obtain granules The regenerated fine aggregate whose diameter is less than 4.75mm, then sieve the regenerated fine agg...

Embodiment 2

[0034] A low-temperature heat treatment regeneration active micropowder of waste concrete, which is composed of 100 parts by weight of waste concrete cement stone powder, 65 parts by weight of stone powder, 0.7 parts by weight of sintering aid, 6 parts by weight of desulfurized gypsum, and 1.0 part by weight of an activator; wherein the activator It consists of 80wt% modified bentonite, 4wt% polyoxyethylene sorbitan monostearate, 7wt% sodium alginate, 4wt% soda ash and 5wt% alkali lignin; the sintering aid is zinc carbonate.

[0035] The preparation steps of the waste concrete low-temperature heat treatment regenerated active micropowder are as follows: 1) Take waste concrete or waste mortar as raw material, first crush it once with a crusher to obtain recycled coarse aggregate with a particle size of less than 19 mm, and then perform secondary crushing to obtain granules The regenerated fine aggregate whose diameter is less than 4.75mm, then sieve the regenerated fine aggregat...

Embodiment 3

[0038] A low-temperature heat treatment regeneration active micropowder of waste concrete, which is composed of 100 parts by weight of waste concrete cement stone powder, 60 parts by weight of stone powder, 0.6 parts by weight of sintering aid, 8 parts by weight of desulfurized gypsum, and 1.2 parts by weight of an activator; wherein the activator It consists of 68wt% of modified bentonite, 11wt% of polyoxyethylene sorbitan monostearate, 9wt% of sodium alginate, 2wt% of soda ash, and 10wt% of alkali lignin; the sintering aid is sodium octanoate.

[0039] The preparation steps of the waste concrete low-temperature heat treatment regenerated active micropowder are as follows: 1) Take waste concrete or waste mortar as raw material, first crush it once with a crusher to obtain recycled coarse aggregate with a particle size of less than 19 mm, and then perform secondary crushing to obtain granules The regenerated fine aggregate whose diameter is less than 4.75mm, then sieve the rege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com