Automatic vending machine

A technology of vending machines and cabinets, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items. It can solve the problems of unfavorable energy saving and environmental protection, high energy consumption, etc. The effect of energy efficiency level improvement and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

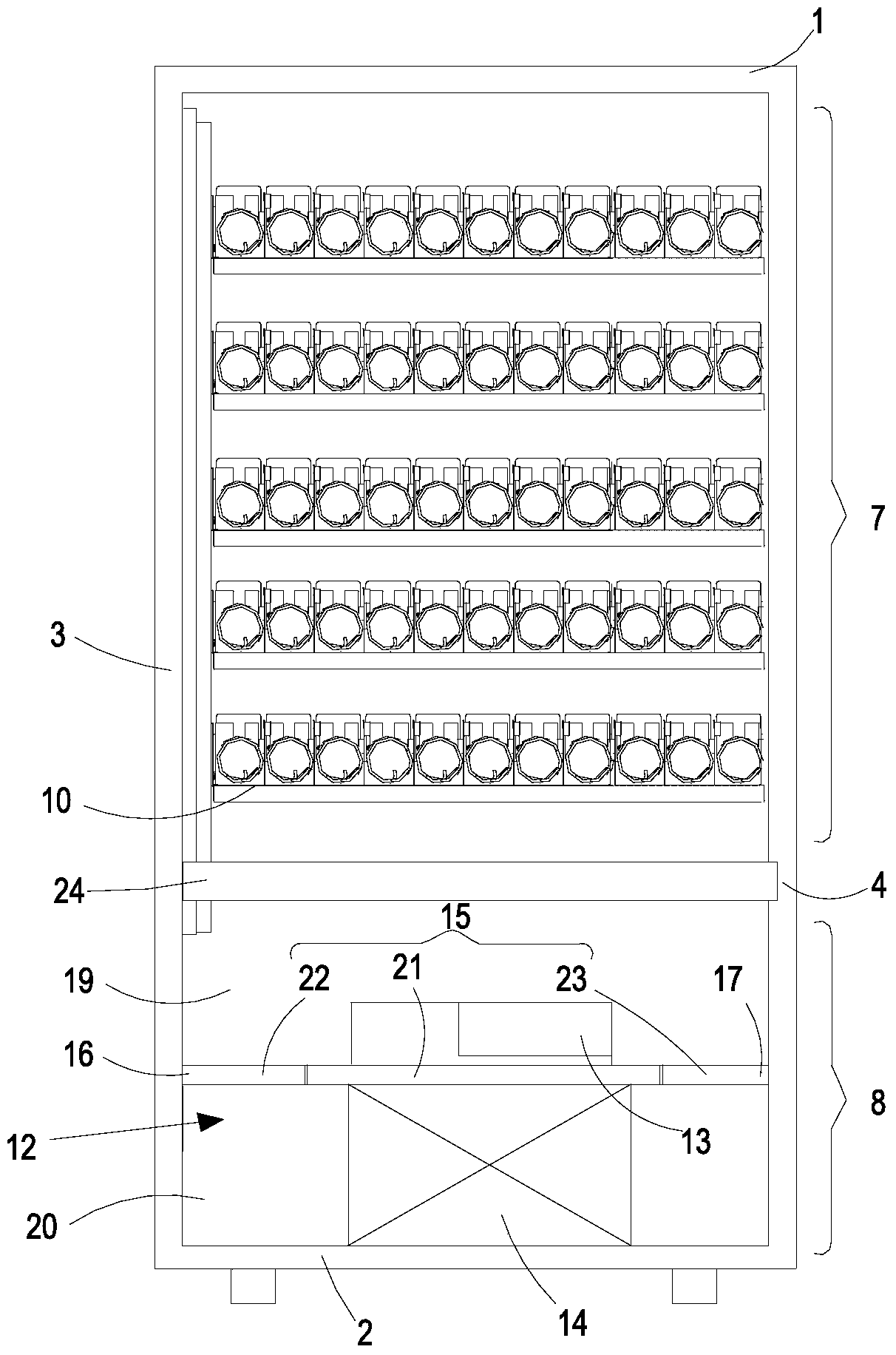

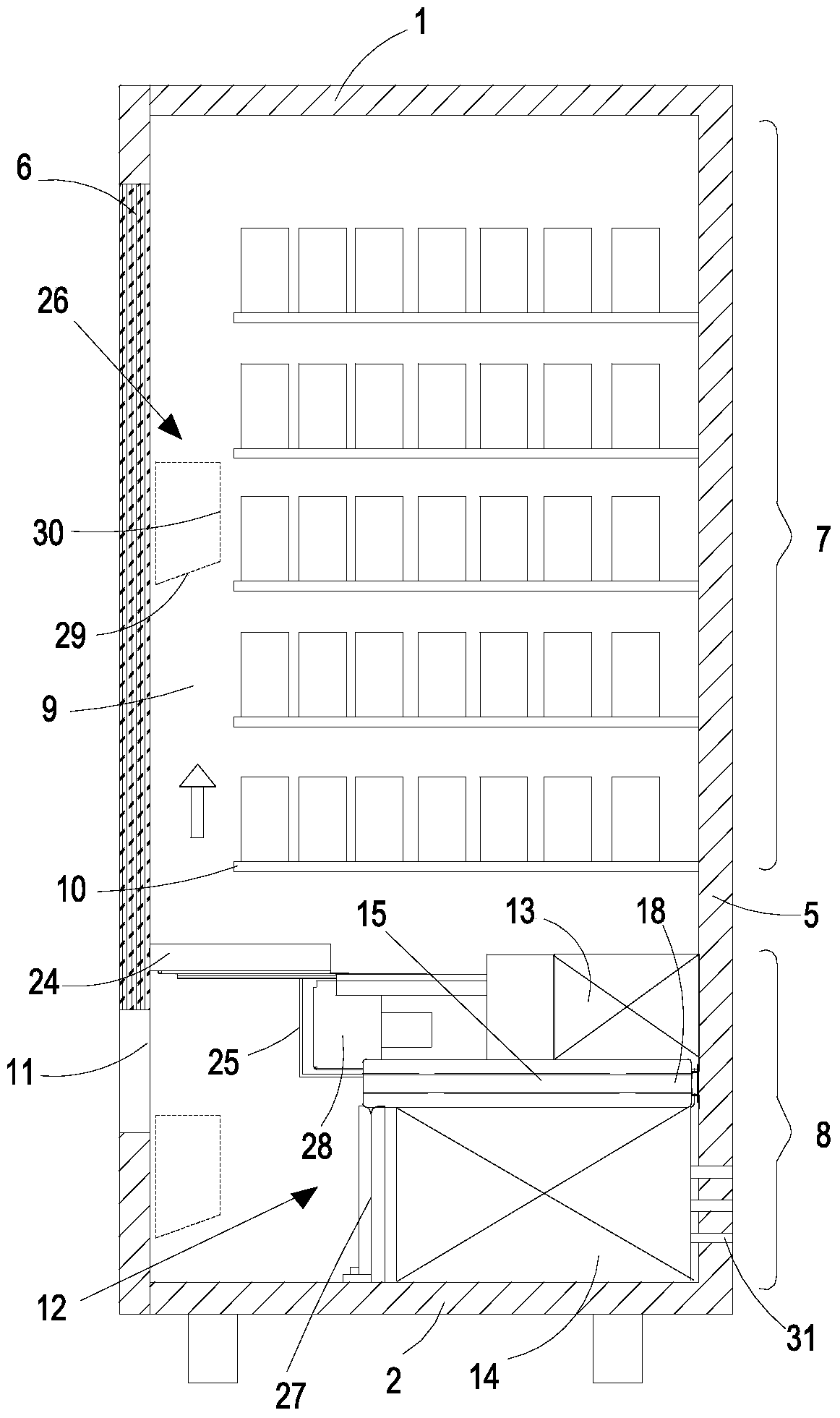

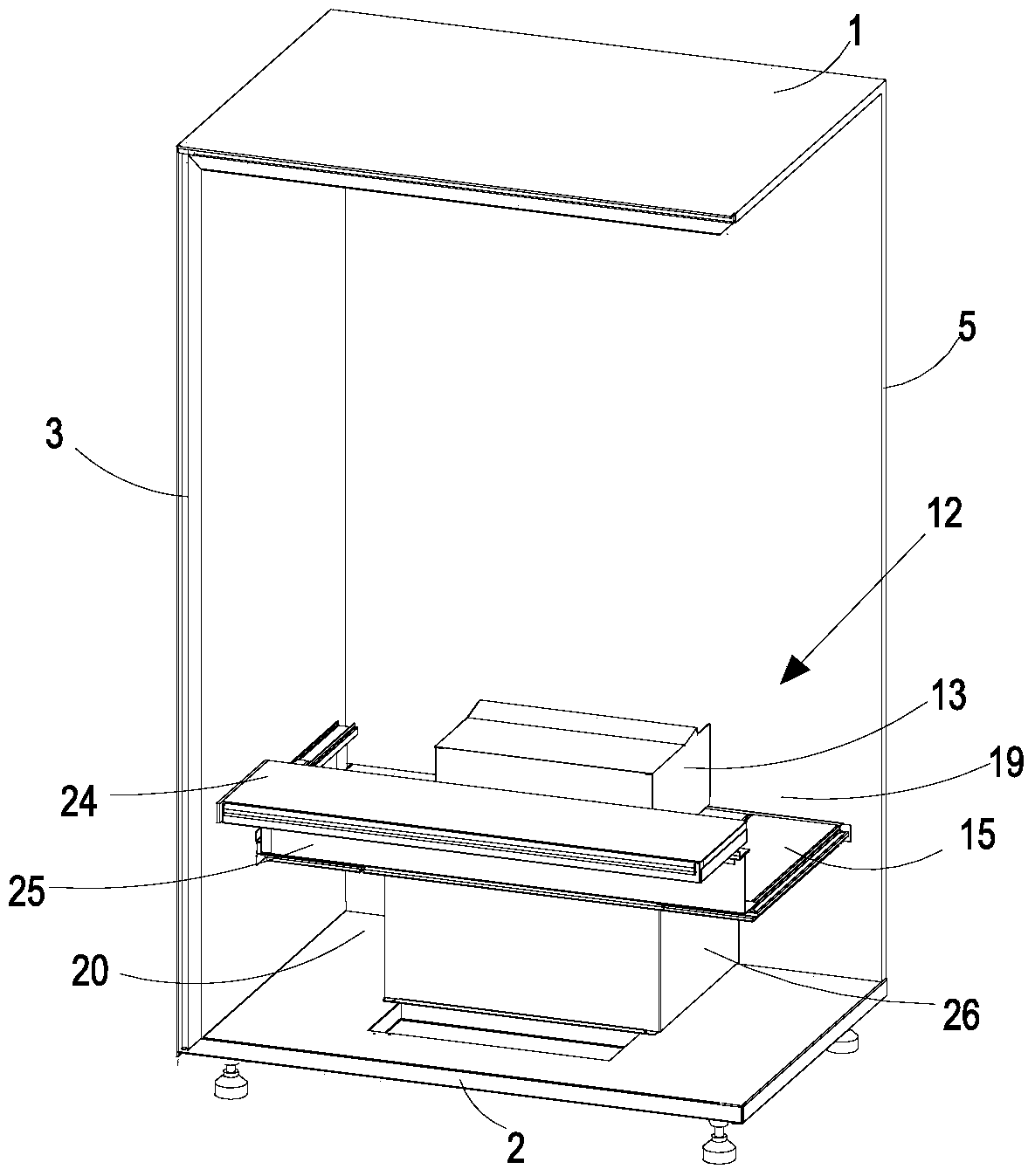

[0021] like figure 1 , 2 The shown automatic vending machine has a cabinet. The cabinet includes a top wall 1, a bottom wall 2, a left side wall 3, a right side wall 4, a rear side wall 5 and a front cabinet door 6. The top wall 1, the left side wall The wall 3, the right side wall 4, the rear side wall 5 and the front cabinet door 6 preferably all adopt cabinet walls with high thermal insulation performance, such as the top wall 1, the left side wall 3, the right side wall 4, and the rear side wall 5. The insulation board of interior filling foaming material is made, and front cabinet door 6 is a transparent door body, then can adopt the heat-insulating glass support of vacuumizing in multilayer. The interior of the cabinet has a produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com