Device and method for regulating humidity of coal powder by utilizing microwave preheating

A preheating and microwave technology, applied in the petroleum industry, coke ovens, etc., can solve the problems of large steam and electricity consumption, inability to meet energy saving, difficult operation and maintenance, etc., achieve low operating costs, improve production environment, and improve coke ovens. stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention are described below through specific embodiments. On the premise that there is no conflict with the purpose of the present invention, the embodiments mentioned below and the technical features in the embodiments can be combined with each other.

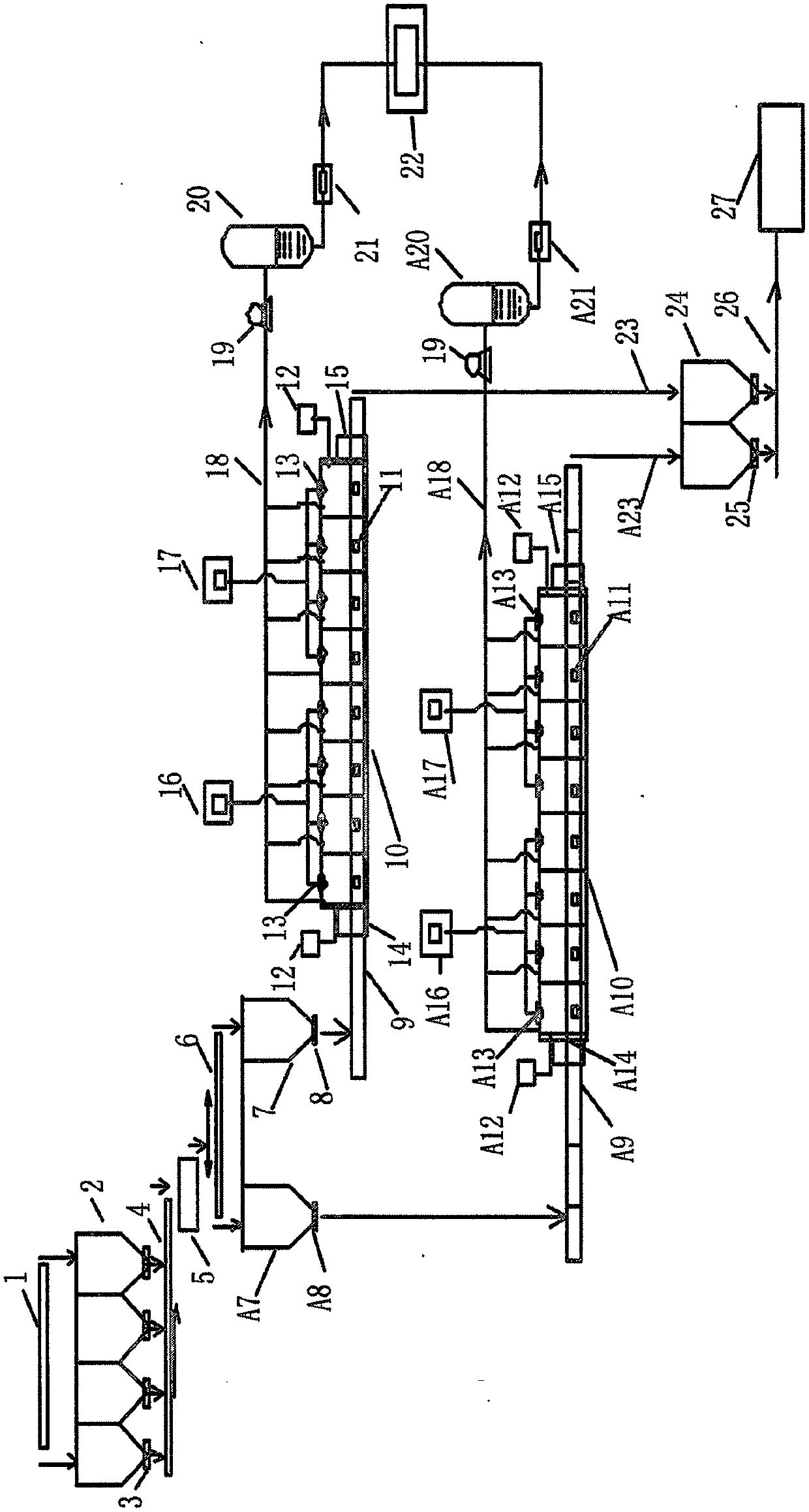

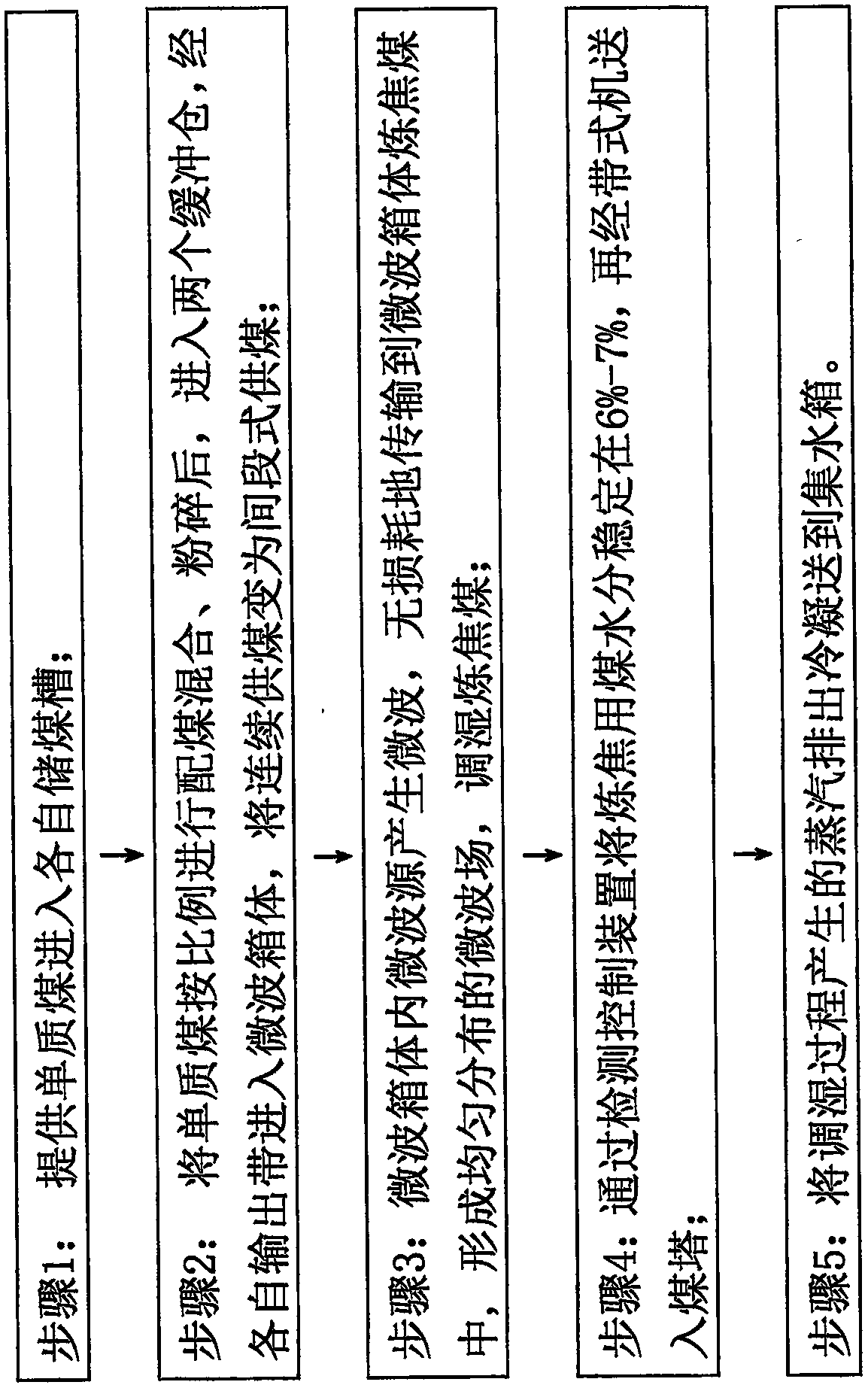

[0036] The technical scheme adopted in the present invention is: a single type of coal enters the respective coal storage tanks through a belt machine, and an automatic coal blending device is installed under the coal storage tanks, and the feeding amount is controlled according to a given value, and the coal is laid on the coal blending belt in turn. After entering the pulverizer and crushing, it enters two buffer bins, and enters the microwave box through their respective output belts, changing the continuous coal supply into interval coal supply. The microwave source in the microwave box generates microwaves, which are transmitted to the coking coal in the microwave box without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com