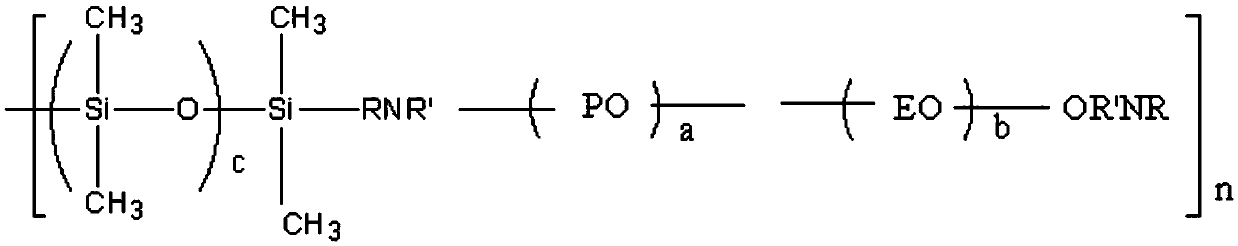

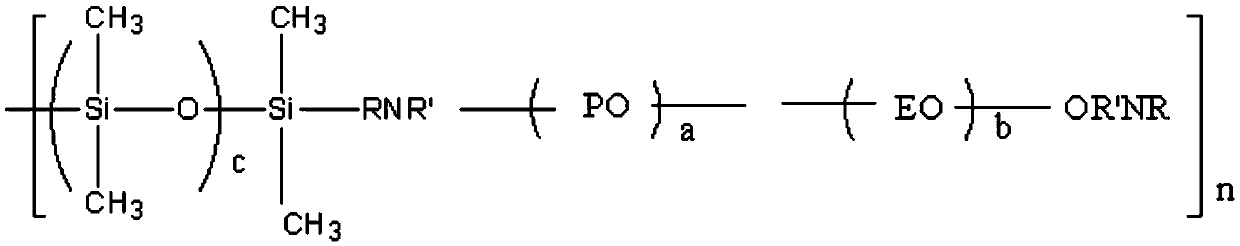

Ternary polymerization block polyether amino silicon oil softening agent and preparing method thereof

A ternary copolymerization block and polyether amino technology, applied in the field of softeners, can solve problems such as yellowing, reducing fabric comfort and hygroscopicity, and achieve the effect of improving wearability and excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Hydrogen double head A40g and D 4 1000g, heated up to 50°C, and reacted for 18 hours to obtain a terminal hydrosiloxane intermediate.

[0028] (2) 2000g of terminal hydrosiloxane intermediate and 45g of allyl polyoxyethylene polyoxypropylene epoxy ether, 20g of isopropanol, 0.2g of chloroplatinic acid, heated up to 80°C under the protection of nitrogen, and reacted After 3-4 hours, epoxy-terminated polyether silicone oil was obtained.

[0029] (3) 2000 g of epoxy-terminated polyether silicone oil, 150 g of amino polyether, and 400 g of isopropanol were heated to 80° C. under the protection of nitrogen, and reacted for 9 hours to obtain ternary copolymerized block polyether amino silicone oil.

[0030] (4) 200g of ternary copolymerization block polyether amino silicone oil, 100g of fatty alcohol polyoxyethylene ether, 5g of acetic acid, 695g of deionized water, and obtain the ternary copolymerization block polyether amino silicone oil emulsion through emulsification...

Embodiment 2

[0032] (1) Hydrogen double head A40g and D 4 1000g, heated up to 60°C, and reacted for 18 hours to obtain a terminal hydrosiloxane intermediate.

[0033] (2) 2000g of terminal hydrosiloxane intermediate and 30g of allyl polyoxyethylene polyoxypropylene epoxy ether, 20g of isopropanol, 0.2g of chloroplatinic acid, heated up to 80°C under the protection of nitrogen, and reacted After 4 hours, epoxy-terminated polyether silicone oil was obtained.

[0034] (3) 2000 g of epoxy-terminated polyether silicone oil, 150 g of amino polyether, and 400 g of isopropanol were heated to 90° C. under the protection of nitrogen, and reacted for 10 hours to obtain terpolymerized block polyether amino silicone oil.

[0035] (4) 300g of ternary copolymerization block polyether amino silicone oil, 100g of fatty alcohol polyoxyethylene ether, 5g of acetic acid, 695g of deionized water, and obtain the ternary copolymerization block polyether amino silicone oil emulsion through emulsification reactio...

Embodiment 3

[0037] (1) Hydrogen double head A40g and D 4 1000g, heated up to 50°C, and reacted for 20 hours to obtain a terminal hydrosiloxane intermediate.

[0038] (2) 1000g of terminal hydrosiloxane intermediate and 20g of allyl polyoxyethylene polyoxypropylene epoxy ether, 10g of isopropanol, 0.1g of chloroplatinic acid, heated up to 90°C under the protection of nitrogen, and reacted After 4 hours, epoxy-terminated polyether silicone oil was obtained.

[0039] (3) 1000 g of epoxy-terminated polyether silicone oil, 80 g of amino polyether, and 150 g of isopropanol were heated to 90° C. under the protection of nitrogen, and reacted for 10 hours to obtain terpolymerized block polyether amino silicone oil.

[0040] (4) 400g of ternary copolymerization block polyether amino silicone oil, 100g of fatty alcohol polyoxyethylene ether, 5g of acetic acid, 695g of deionized water, through emulsification reaction to obtain ternary copolymerization block polyether amino silicone oil emulsion, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com