Polyethylene double-side composite waterproof coiled material

A waterproof membrane and polyethylene technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of weak adhesion, softness and tolerance, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

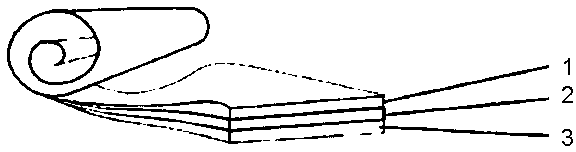

[0007] A polyethylene double-sided composite waterproof roll material is composed of an inner layer 1, an outer layer 3 and a middle layer 2. The inner layer is composed of polypropylene filament non-woven fabric, the outer layer is composed of polyester filament non-woven fabric, the middle layer is a sheet made of polyethylene resin, the middle layer is composited between the inner layer and the outer layer, and the thickness of the middle layer is greater than The thickness of the inner and outer layers. The invention can be constructed coldly and cemented wet, and has the advantages of convenient operation, strong cohesive force, good stability, high tensile strength, high elongation, low temperature flexibility, good heat resistance, corrosion resistance, radiation resistance and the like. The invention can be widely used in waterproofing of various roofs in industry and construction, building waterproofing projects such as basements, reservoirs, dams, highway tunnels, el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com